Njengengxenye eyinhloko yezinhlelo zanamuhla zokuhlanza igesi yoketshezi,Ama-nozzle e-silicon carbide e-FGDidlala indima ebalulekile emikhakheni yezimboni njengamandla okushisa kanye ne-metallurgy. Le nozzle ye-silicon carbide ceramic ixazulule ngempumelelo i-bottleneck yobuchwepheshe yama-nozzle ensimbi yendabuko ngaphansi kokugqwala okunamandla kanye nezimo zokuguguleka okuphezulu ngokuklama okusha kwesakhiwo kanye nokuthuthukiswa kwezinto, okuthuthukisa kakhulu ukusebenza kahle kwe-desulfurization.

1, Izakhiwo zezinto zibeka isisekelo sokusebenza

Ubulukhuni bukaMohsizitsha zobumba ze-silicon carbideifinyelela ku-9.2, ilandela idayimane kuphela, futhi ukuqina kwayo kokuqhekeka kuphindwe kathathu kunokwe-alumina ceramics. Lesi sakhiwo sekristalu esihlanganisiwe sinikeza le nto ukumelana okuhle kakhulu nokuguguleka, futhi ngaphansi kokuthinteka kwe-slurry eshesha kakhulu equkethe amakristalu e-gypsum (isilinganiso sokugeleza kufika ku-12m/s), izinga lokuguguleka kobuso liyi-1/20 kuphela le-nozzles yensimbi. Endaweni eshintshana nge-acid-base enenani le-pH elingu-4-10, izinga lokumelana nokugqwala kwe-silicon carbide lingaphansi kuka-0.01mm/ngonyaka, okungcono kakhulu kunensimbi engagqwali engu-316L engu-0.5mm/ngonyaka.

I-coefficient yokwandisa ukushisa kwezinto (4.0 × 10 ⁻⁶/℃) iseduze neyensimbi, futhi isengagcina ukuqina kwesakhiwo ngaphansi komehluko wokushisa ongu-150 ℃. I-silicon carbide ceramics elungiselelwe ngenqubo yokusabela inamandla angaphezu kuka-98% kanye ne-porosity engaphansi kuka-0.5%, okuvimbela ngempumelelo umonakalo wesakhiwo obangelwa ukungena okuphakathi.

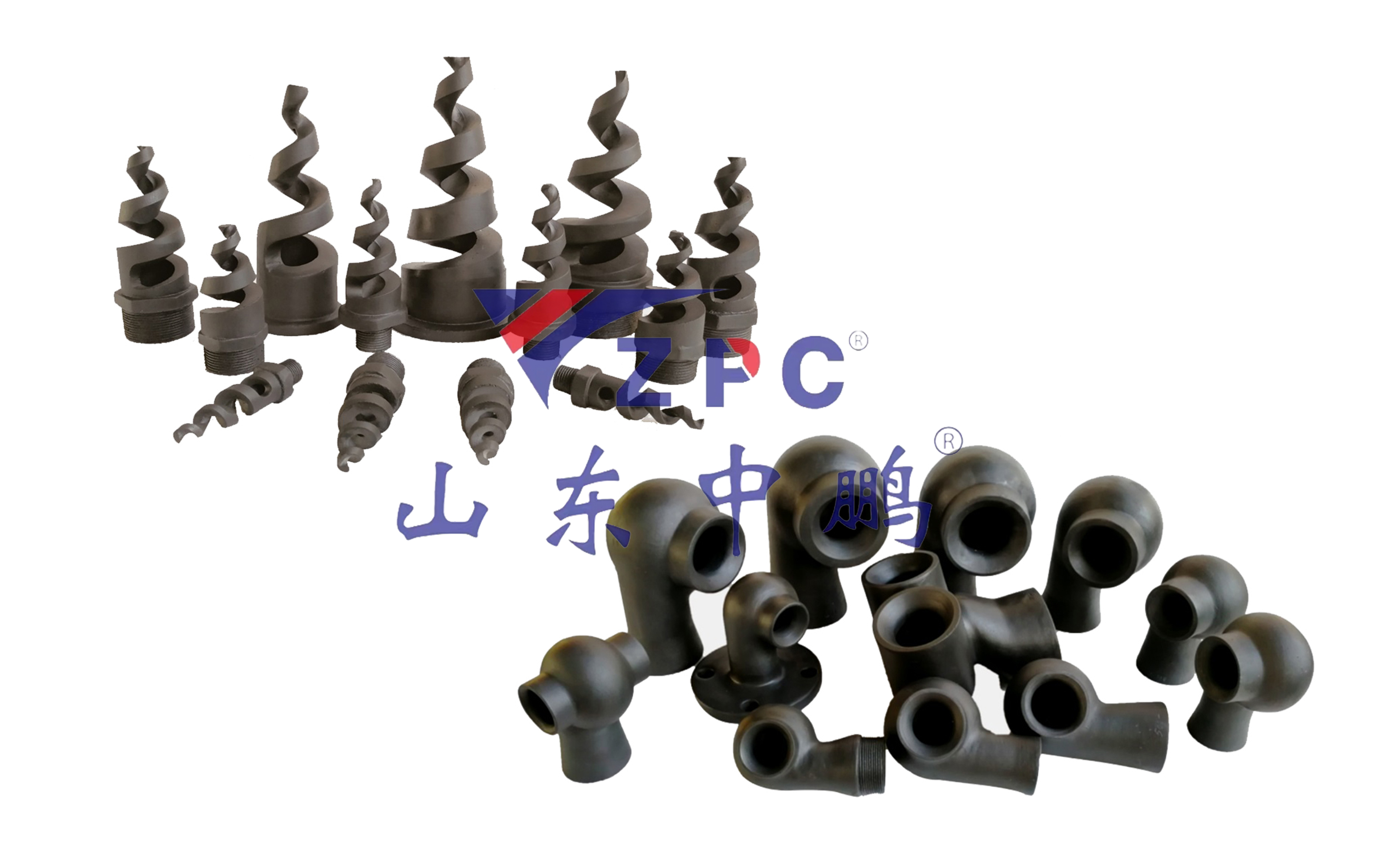

2, Indlela yokwenza i-atomization ibe nembile kanye nokulawula insimu yokugeleza

Iumlomo ojikelezayo we-silicon carbidekwandisa kakhulu isivinini sokuzungeza kwe-slurry, futhi ngokuvulwa okuqondile kokuphuma, iphula i-slurry ye-limestone ibe amaconsi amancane nafanayo. Izinga lokumboza insimu yokufutha eyindilinga eyakhiwe yilesi sakhiwo likhulu kakhulu, futhi isikhathi sokuhlala kwamaconsi embhoshongweni sandiswa sibe yimizuzwana emi-2-3, okuphakeme ngama-40% kunesezimbobo zendabuko.

3, Ukufanisa uhlelo kanye nokwenza ngcono ubunjiniyela

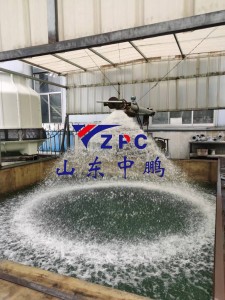

Embhoshongweni ojwayelekile wokufutha,ama-nozzle e-silicon carbide FGDKusetshenziswa ibhodi le-chessboard, ngesikhala esiphindwe ka-1.2-1.5 kunobubanzi bekhoni yokufafaza, okwenza izendlalelo ezi-3-5 zokumboza. Lokhu kulungiswa kuqinisekisa ukuthi ukumbozwa kwengxenye yombhoshongo wokususa i-sulfur kudlula u-200%, okuqinisekisa ukuthintana okwanele phakathi kwegesi yomoya kanye ne-slurry. Ngesilinganiso sokugeleza kombhoshongo ongenalutho esingu-3-5 m/s, ukulahlekelwa kwengcindezi yesistimu kulawulwa ngaphakathi kwebanga elingu-800-1200 Pa.

Idatha yokusebenza ikhombisa ukuthi ukusebenza kahle kokususa i-sulfurization kohlelo lwe-FGD kusetshenziswa ama-nozzle e-silicon carbide kuhlala kuzinzile ngaphezu kuka-97.5%, kanti okuqukethwe komswakama kwemikhiqizo ye-gypsum kuncishisiwe kwaba ngaphansi kuka-10%. Umjikelezo wokugcinwa kwemishini unwetshiwe kusukela ezinyangeni ezi-3 zama-nozzle ensimbi kuya eminyakeni emi-3, kanti izindleko zokushintsha izingxenye ezisele zehle ngo-70%.

Ukusetshenziswa kwalokhuI-nozzle ye-FGDKuphawula igxathu elisuka emishinini yokuvikela imvelo ebanzi kuya kweqondile. Ngokuvuthwa kobuchwepheshe be-ceramic bokunyathelisa be-3D, ukwakheka kwe-topology optimization kwesakhiwo sesiteshi sokugeleza kungase kubonakale esikhathini esizayo, okungathuthukisa ukusebenza kahle kwe-atomization ngo-15-20% futhi kukhuthaze ubuchwepheshe bokukhipha umoya obuphansi kakhulu ukuze kungene esigabeni esisha sentuthuko.

Isikhathi sokuthunyelwe: Mashi-24-2025