A matsayin babban ɓangaren tsarin tsarkake iskar gas na zamani,bututun FGD na silicon carbidesuna taka muhimmiyar rawa a fannonin masana'antu kamar wutar lantarki da aikin ƙarfe. Wannan bututun ƙarfe na silicon carbide ya yi nasarar magance matsalar fasaha ta bututun ƙarfe na gargajiya a ƙarƙashin tsananin tsatsa da yanayin lalacewa ta hanyar ƙira mai inganci da ci gaban kayan aiki, wanda hakan ya inganta ingancin cire sulfur.

1, Kayan aiki suna kafa harsashin aiki

Taurin Mohs nayumburan silicon carbideYa kai 9.2, wanda ya fi lu'u-lu'u ta biyu, kuma ƙarfin karyewar sa ya ninka na yumburan alumina sau uku. Wannan tsarin lu'u-lu'u mai kama da covalent yana ba wa kayan kyakkyawan juriya ga gogewa, kuma ƙarƙashin tasirin slurry mai sauri mai ɗauke da lu'ulu'u na gypsum (ƙarfin kwarara har zuwa 12m/s), ƙimar lalacewa ta saman shine 1/20 kawai na bututun ƙarfe. A cikin yanayin canzawa na acid-base tare da ƙimar pH na 4-10, ƙimar juriyar tsatsa na silicon carbide bai wuce 0.01mm/shekara ba, wanda ya fi kyau fiye da 0.5mm/shekara na bakin karfe 316L.

Ma'aunin faɗaɗa zafi na kayan (4.0 × 10 ⁻⁶/℃) yana kusa da na ƙarfe, kuma har yanzu yana iya kiyaye daidaiton tsarin a ƙarƙashin bambancin zafin jiki na 150 ℃. Tukwanen silicon carbide da aka shirya ta hanyar tsarin haɗa sinadarai suna da yawa sama da 98% da kuma porosity na ƙasa da 0.5%, wanda hakan ke hana lalacewar tsarin da matsakaicin shigar ruwa ke haifarwa.

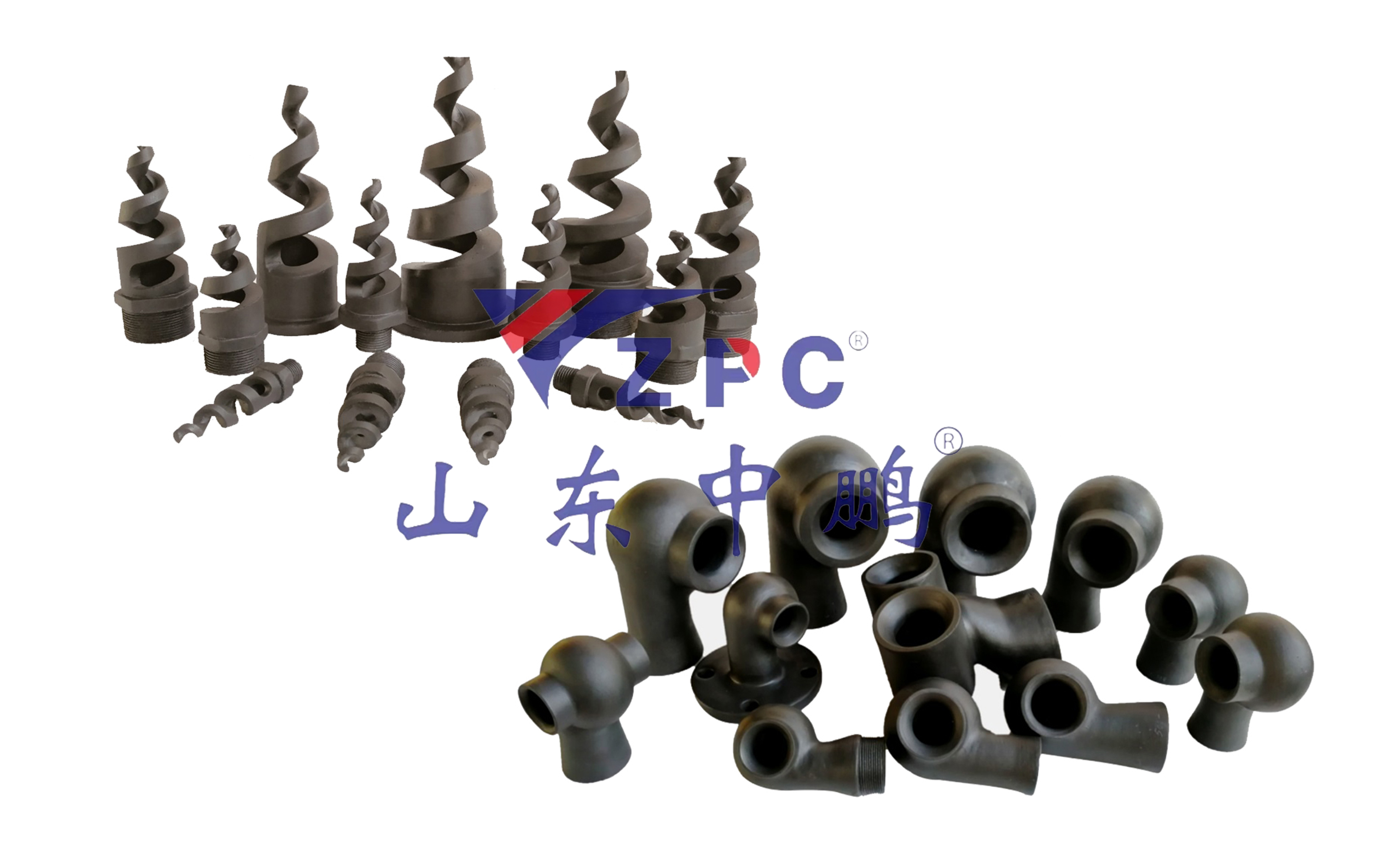

2, tsarin atomization daidaici da kuma kula da filin kwarara

Thebututun ƙarfe mai siffar silicon carbideYana ƙara saurin juyawar slurry sosai, kuma tare da madaidaicin buɗewar fita, yana raba slurry ɗin dutse zuwa ƙananan ɗigon ruwa iri ɗaya. Yawan rufe filin feshi mai siffar konkoli da wannan tsari ya samar yana da girma sosai, kuma lokacin zama na ɗigon ruwa a cikin hasumiyar yana ƙaruwa zuwa daƙiƙa 2-3, wanda ya fi na bututun ƙarfe na gargajiya girma da kashi 40%.

3, Daidaita tsarin da inganta injiniyanci

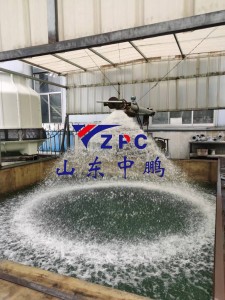

A cikin hasumiyar feshi ta yau da kullun,bututun FGD na silicon carbideAn yi amfani da shi ta hanyar zane-zane, tare da tazara sau 1.2-1.5 diamita na feshi, wanda ke samar da yadudduka 3-5 na rufewa. Wannan tsari yana tabbatar da cewa murfin hasumiyar desulfurization ya wuce kashi 200%, yana tabbatar da isasshen hulɗa tsakanin iskar gas da slurry. Tare da kwararar hasumiya mara komai na 3-5 m/s, ana sarrafa asarar matsin lamba na tsarin a cikin kewayon 800-1200 Pa.

Bayanan aiki sun nuna cewa ingancin tsarin FGD ta amfani da bututun silicon carbide ya kasance daidai da kashi 97.5%, kuma danshi na kayayyakin gypsum ya ragu zuwa ƙasa da kashi 10%. An tsawaita lokacin kula da kayan aiki daga watanni 3 na bututun ƙarfe zuwa shekaru 3, kuma farashin maye gurbin kayan gyara ya ragu da kashi 70%.

Amfani da wannanbututun FGDyana nuna tsalle daga kayan aikin kariya ga muhalli masu yawa zuwa ingantattun kayan aikin kariya. Tare da balaga da fasahar yumbu ta bugu ta 3D, ƙirar inganta yanayin tsarin kwararar ruwa za a iya cimmawa nan gaba, wanda zai iya ƙara inganta ingancin atomization da kashi 15-20% da kuma haɓaka fasahar fitar da hayaki mai ƙarancin iska don shiga sabon matakin ci gaba.

Lokacin Saƙo: Maris-24-2025