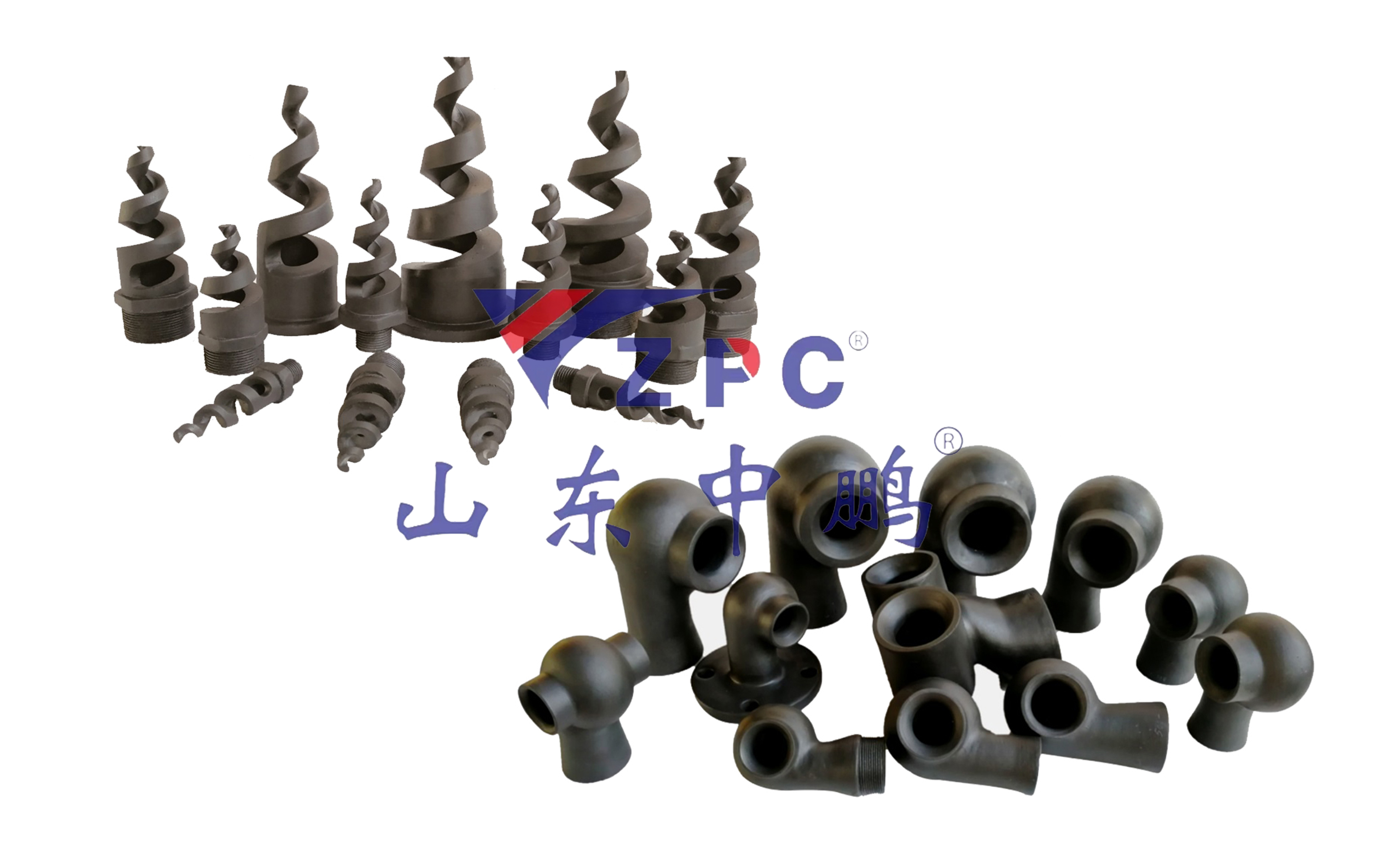

Dịka akụkụ bụ isi nke sistemụ nhicha gas flue nke oge a,FGD nozzles silicon carbidena-arụ ọrụ dị oke mkpa n'ọrụ ụlọ ọrụ mmepụta ihe dịka ike okpomọkụ na igwe ígwè. Ihe mkpuchi seramiiki silicon carbide a edozila nsogbu teknụzụ nke ihe mkpuchi ígwè ọdịnala n'okpuru nchara siri ike na ọnọdụ iyi dị elu site na imewe ihe owuwu ọhụrụ na ihe ndị mepụtara, na-eme ka arụmọrụ desulfurization ka mma nke ukwuu.

1, Ihe onwunwe na-atọ ntọala maka arụmọrụ

Ike siri ike nke Mohsseramiiki silicon carbideỌ na-eru 9.2, nke abụọ karịa dayamọnd, ike mgbawa ya dịkwa okpukpu atọ karịa nke seramiiki alumina. Nhazi kristal covalent a na-enye ihe ahụ ezigbo ike mgbochi abrasion, n'okpuru mmetụta nke slurry dị elu nwere kristal gypsum (ọsọ mmiri ruru 12m/s), ọnụego iyi elu bụ naanị 1/20 nke nozzles ígwè. N'ebe mgbanwe acid-base nwere uru pH nke 4-10, ọnụego iguzogide corrosion nke silicon carbide erughị 0.01mm/afọ, nke ka mma karịa 0.5mm/afọ nke ígwè anaghị agba nchara 316L.

Oke mgbasawanye okpomọkụ nke ihe ahụ (4.0 × 10 ⁻⁶/℃) dị nso na nke ígwè, ọ ka nwere ike ịnọgide na-enwe nkwụsi ike nhazi n'okpuru ọdịiche okpomọkụ nke 150 ℃. Seramiki silikọn carbide nke usoro mmeghachi omume na-emepụta nwere njupụta karịrị 98% na porosity nke na-erughị 0.5%, nke na-egbochi mmebi nhazi nke nnukwu ntinye na-akpata.

2, usoro atomization nkenke na njikwa ubi eruba

Ihesilicon carbide gburugburu nozuluỌ na-eme ka ọsọ nke slurry ahụ na-agbagharị nke ukwuu, sitekwa na oghere ọpụpụ ziri ezi, ọ na-agbaji slurry limestone ka ọ bụrụ obere ntapụ mmiri na otu nha. Oke mkpuchi oghere conical nke usoro a mepụtara buru ibu nke ukwuu, oge obibi nke ntapụ mmiri dị n'ụlọ elu ahụ na-agbatị ruo sekọnd 2-3, nke dị elu karịa 40% karịa nke nozzles ọdịnala.

3, Nhazi sistemụ na nhazi injinia

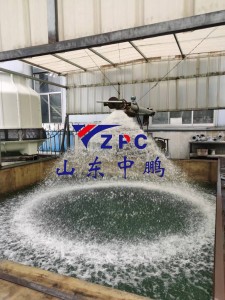

N'ụlọ elu a na-agba mmiri nkịtị,ihe mkpuchi FGD nke silicon carbideA na-eji usoro chessboard eme ihe, ya na oghere dị okpukpu 1.2-1.5 nke dayameta cone nke a na-agba, na-eme ka oyi akwa 3-5 nke mkpuchi kpuchie. Nhazi a na-eme ka mkpuchi nke ụlọ elu desulfurization gafere 200%, na-eme ka njikọ zuru oke n'etiti gas flue na slurry ahụ. Site na ọnụego mmiri ụlọ elu efu nke 3-5 m/s, a na-achịkwa mfu nrụgide sistemụ n'ime oke 800-1200 Pa.

Data ọrụ na-egosi na arụmọrụ nke sistemụ FGD site na iji silicon carbide nozzles ka kwụsiri ike na ihe karịrị 97.5%, ọdịnaya mmiri nke ngwaahịa gypsum ewedakwara ala ruo n'okpuru 10%. A gbatịala usoro mmezi akụrụngwa site na ọnwa atọ maka nozzles ígwè ruo afọ atọ, ọnụ ahịa nke nnọchi akụkụ mapụtara ebelatala site na 70%.

Ojiji nke aFGD nozuluna-egosi mmụba site na ngwa nchekwa gburugburu ebe obibi sara mbara ruo na nke ziri ezi. Site na ntozu oke nke teknụzụ seramiiki mbipụta 3D, a ga-emezu nhazi nhazi topology nke nhazi ọwa mmiri n'ọdịnihu, nke nwere ike imeziwanye arụmọrụ atomization site na 15-20% ma kwalite teknụzụ mmepụta dị oke ala iji banye n'ọkwa ọhụrụ nke mmepe.

Oge ozi: Maachị-24-2025