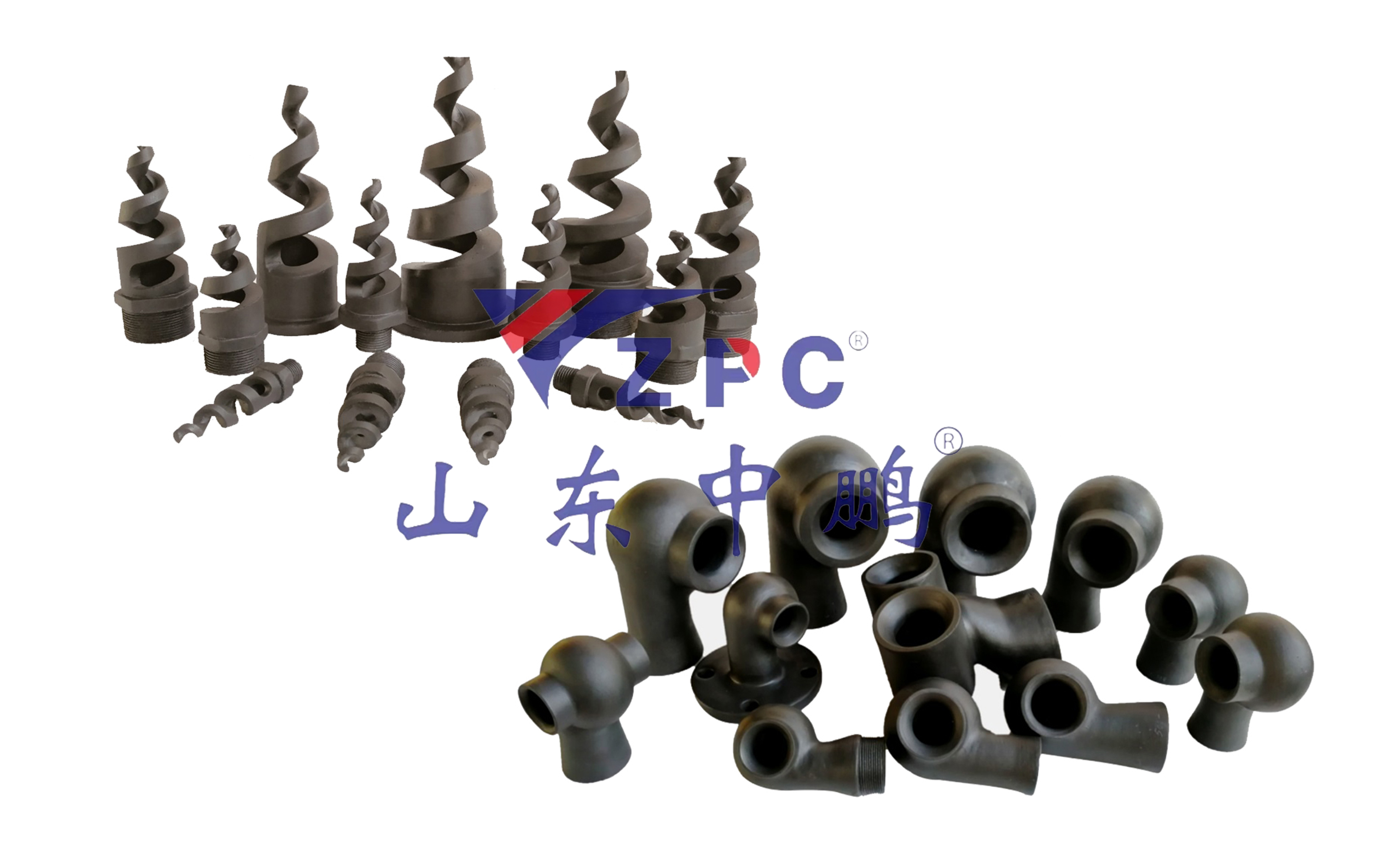

Sechinhu chikuru chemazuva ano chekuchenesa magasi emvura,silicon carbide FGD mokugezerainoita basa rakakosha muminda yemaindasitiri senge simba rekupisa uye simbi. Iyi silicon carbide ceramic nozzle yakagadzirisa zvinobudirira dambudziko rema nozzle esimbi echinyakare pasi pengura yakasimba uye mamiriro ekusakara zvakanyanya kuburikidza nekugadzira zvivakwa zvitsva uye kufambira mberi kwezvinhu, zvichivandudza zvakanyanya kushanda kwe desulfurization.

1, Zvimiro zvezvinhu zvinoisa hwaro hwekushanda zvakanaka

Kuomarara kweMohszviumbwa zvesimbi zvesilicon carbideinosvika 9.2, yechipiri kune dhaimani, uye kusimba kwayo kwekutyoka kwakapetwa katatu pane alumina ceramics. Chimiro ichi chekristaro checovalent chinopa chinhu ichi kusimba kwakanaka kwekukwesha, uye pasi pekukanganiswa nekutsvedza kwemvura ine gypsum crystals (kuyerera kwemvura kusvika 12m/s), kukwesha kwemvura pamusoro pechinhu ichi kunongova 1/20 chete yesimbi. Munzvimbo ine acid-base alternating ine pH ye4-10, kusimba kwesimbi yesilicon carbide kuri pasi pe0.01mm/gore, izvo zviri nani kupfuura 0.5mm/gore ye316L stainless steel.

Kuwanda kwekupisa kwezvinhu (4.0 × 10 ⁻⁶/℃) kwakafanana nesimbi, uye kunogona kuramba kwakagadzikana kwechimiro kana tembiricha yasiyana ne150 ℃. Zvigadzirwa zvesilicon carbide zvakagadzirwa nemaitiro ekuita sintering zvine huwandu hwepamusoro pe98% uye porosity iri pasi pe0.5%, zvichidzivirira kukuvara kwechimiro kunokonzerwa nekupinda kwepakati.

2, Kururama kweatomization mashandiro uye kuyerera kwemunda kudzora

Iyomuromo wesimbi wesilicon carbideinowedzera zvakanyanya kumhanya kwekutenderera kwetsvina, uye nekuvhura kwakanyatsojeka, inoputsa slurry ye limestone kuita madonhwe madiki uye akafanana. Mwero wekufukidza munda we spray une hollow conical unoumbwa nechimiro ichi wakakura kwazvo, uye nguva yekugara kwemadonhwe mushongwe inowedzerwa kusvika kumasekonzi maviri kusvika matatu, 40% yakakwira kupfuura ye nozzles dzechinyakare.

3, Kufananidza masisitimu uye kugadzirisa mashandiro emainjiniya

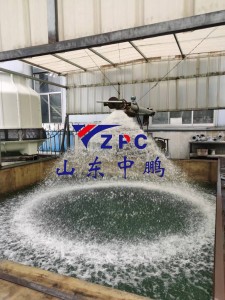

Mushongwe yekupfapfaidza yakajairika,simbi dzeFGD dzesilicon carbideZvakarongwa nenzira yechessboard zvinoshandiswa, ne spaceship ye 1.2-1.5 yakapetwa dhayamita ye spray cone, zvichiita 3-5 layers ye overlay. Iyi gadziriro inoita kuti cross-sectional coverage ye desulfurization tower ipfuure 200%, zvichiita kuti pave nekubatana kwakakwana pakati pe flue gas ne slurry. Ne empty tower flow rate ye 3-5 m/s, system pressure loss inodzorwa mukati me 800-1200 Pa.

Ruzivo rwekushanda runoratidza kuti kushanda zvakanaka kweFGD system uchishandisa silicon carbide nozzles kunoramba kwakagadzikana pa97.5%, uye hunyoro hwezvigadzirwa zvegypsum hwakaderedzwa kusvika pasi pe10%. Nguva yekugadzirisa michina yakawedzerwa kubva pamwedzi mitatu yesimbi nozzles kusvika kumakore matatu, uye mutengo wekutsiva zvikamu wakaderera ne70%.

Kushandiswa kweizviMuromo weFGDchiratidzo chekuchinja kubva pamidziyo yakakura kuenda kune chaiyo yekuchengetedza zvakatipoteredza. Nekukura kwetekinoroji ye3D printing ceramic, dhizaini ye topology yekugadzirisa chimiro che flow channel inogona kuzadzikiswa mune ramangwana, izvo zvinogona kuwedzera kushanda kweatomization ne15-20% uye kukurudzira tekinoroji ye ultra-low emission kuti ipinde padanho idzva rekukura.

Nguva yekutumira: Kurume-24-2025