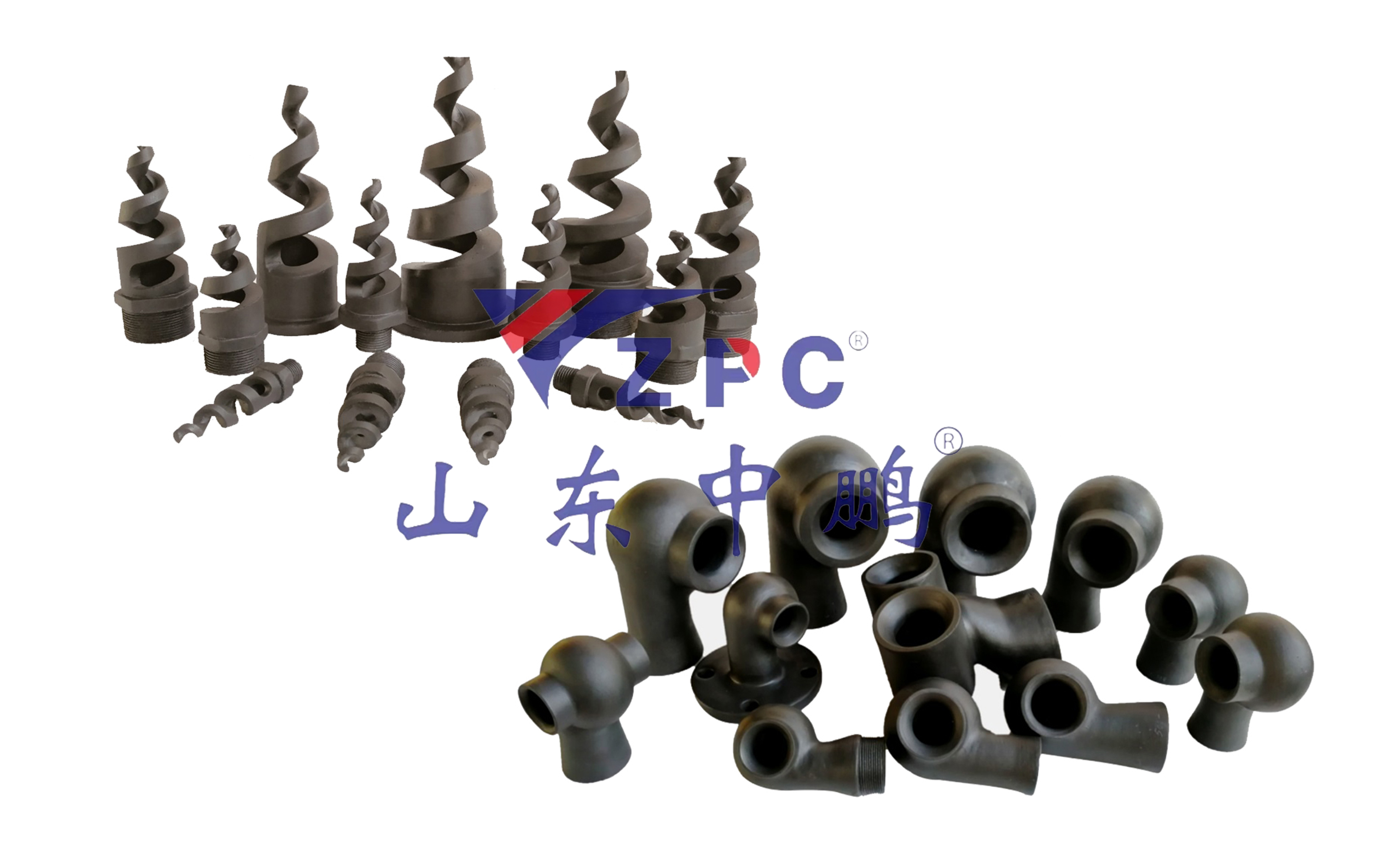

Njengenxalenye ephambili yeenkqubo zanamhlanje zokucoca igesi yombhobho,Ii-FGD Nozzles ze-silicon carbideidlala indima ebalulekileyo kwimimandla yemizi-mveliso efana namandla obushushu kunye ne-metallurgy. Le nozzle ye-silicon carbide ceramic isombulule ngempumelelo imiqobo yobugcisa yee-nozzle zesinyithi zendabuko phantsi kokugqwala okunamandla kunye neemeko zokuguguleka okuphezulu ngoyilo olutsha lwesakhiwo kunye nophuhliso lwezinto, nto leyo ephucula kakhulu ukusebenza kakuhle kwe-desulfurization.

1, Iimpawu zezinto ezibonakalayo zibeka isiseko sokusebenza

Ubunzima bukaMohsiiseramikhi zesilicon carbideIfikelela kwi-9.2, ilandela idayimani kuphela, kwaye ukuqina kwayo kokuqhekeka kuphindwe kathathu kunokwe-alumina ceramics. Olu lwakhiwo lwekristale ye-covalent lunika le nto ukumelana nokukrala okugqwesileyo, kwaye phantsi kwempembelelo ye-slurry ekhawulezayo equlethe iikristale ze-gypsum (isantya sokuhamba ukuya kuthi ga kwi-12m/s), izinga lokuguguleka komphezulu liyi-1/20 kuphela lee-nozzles zesinyithi. Kwindawo etshintshanayo ne-acid-base enexabiso le-pH eliyi-4-10, izinga lokuxhathisa ukugqwala kwe-silicon carbide lingaphantsi kwe-0.01mm/ngonyaka, elingcono kakhulu kune-0.5mm/ngonyaka yentsimbi engagqwaliyo eyi-316L.

I-coefficient yokwandiswa kobushushu bezinto (4.0 × 10 ⁻⁶/℃) isondele kweyentsimbi, kwaye isenokugcina uzinzo lwesakhiwo phantsi komahluko wobushushu we-150 ℃. Iiseramikhi ze-silicon carbide ezilungiselelwe ngenkqubo yokusila i-reaction zinoxinano olungaphezulu kwe-98% kunye ne-porosity engaphantsi kwe-0.5%, nto leyo ethintela ngempumelelo umonakalo wesakhiwo obangelwa kukungena okuphakathi.

2, Indlela yokwenza i-atomization icace kakuhle kunye nolawulo lwentsimi yokuhamba

Iumlomo ojikelezayo we-silicon carbideIyandisa kakhulu isantya sokujika kwe-slurry, kwaye ngomngxuma ochanekileyo wokuphuma, iyawaphula ama-slurry e-limestone abe ngamathontsi amancinci nafanayo. Izinga lokugubungela intsimi yokutshiza e-conical engenanto eyenziwe lolu lwakhiwo likhulu kakhulu, kwaye ixesha lokuhlala kwamathontsi kwinqaba landiswe ukuya kwimizuzwana emi-2-3, liphezulu ngama-40% kunelo lee-nozzles zemveli.

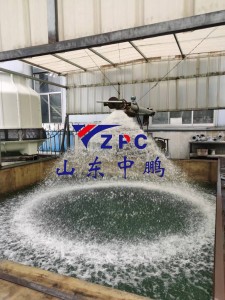

3, Uthelekiso lwenkqubo kunye nokwenza ngcono ubunjineli

Kwinqaba yokutshiza eqhelekileyo,ii-nozzles ze-silicon carbide FGDKusetyenziswa ibhodi yechess, apho isithuba siphindwe kayi-1.2-1.5 ubukhulu bekhowuni yokutshiza, okwenza iileya ezi-3-5 zokugquma. Olu lungiselelo luqinisekisa ukuba ukugquma kwenqaba yokunyibilikisa isulfur kudlula i-200%, kuqinisekisa unxibelelwano olwaneleyo phakathi kwegesi yolwelo kunye ne-slurry. Ngesantya sokuhamba kwenqaba engenanto se-3-5 m/s, ukulahleka koxinzelelo lwenkqubo kulawulwa ngaphakathi koluhlu lwe-800-1200 Pa.

Idatha yokusebenza ibonisa ukuba ukusebenza kakuhle kwenkqubo ye-FGD esebenzisa i-silicon carbide nozzles kuhlala kuzinzile ngaphezulu kwe-97.5%, kwaye umxholo wokufuma weemveliso ze-gypsum uncitshisiwe ukuya ngaphantsi kwe-10%. Umjikelo wokugcinwa kwezixhobo wolulwe ukusuka kwiinyanga ezi-3 kwi-nozzles zesinyithi ukuya kwiminyaka emi-3, kwaye iindleko zokutshintshwa kwezixhobo ezingasetyenziswanga zehle nge-70%.

Ukusetyenziswa kwale ntoImpumlo ye-FGDkuphawula inyathelo elivela kwizixhobo ezibanzi ukuya kwezichanekileyo zokukhusela okusingqongileyo. Ngokukhula kwetekhnoloji yeseramikhi yokushicilela ye-3D, uyilo lwe-topology optimization lwesakhiwo setshaneli yokuhamba kwamanzi lunokuphunyezwa kwixesha elizayo, olunokuphucula ngakumbi ukusebenza kwe-atomization nge-15-20% kwaye lukhuthaze itekhnoloji yokukhupha umoya ephantsi kakhulu ukungena kwinqanaba elitsha lophuhliso.

Ixesha leposi: Matshi-24-2025