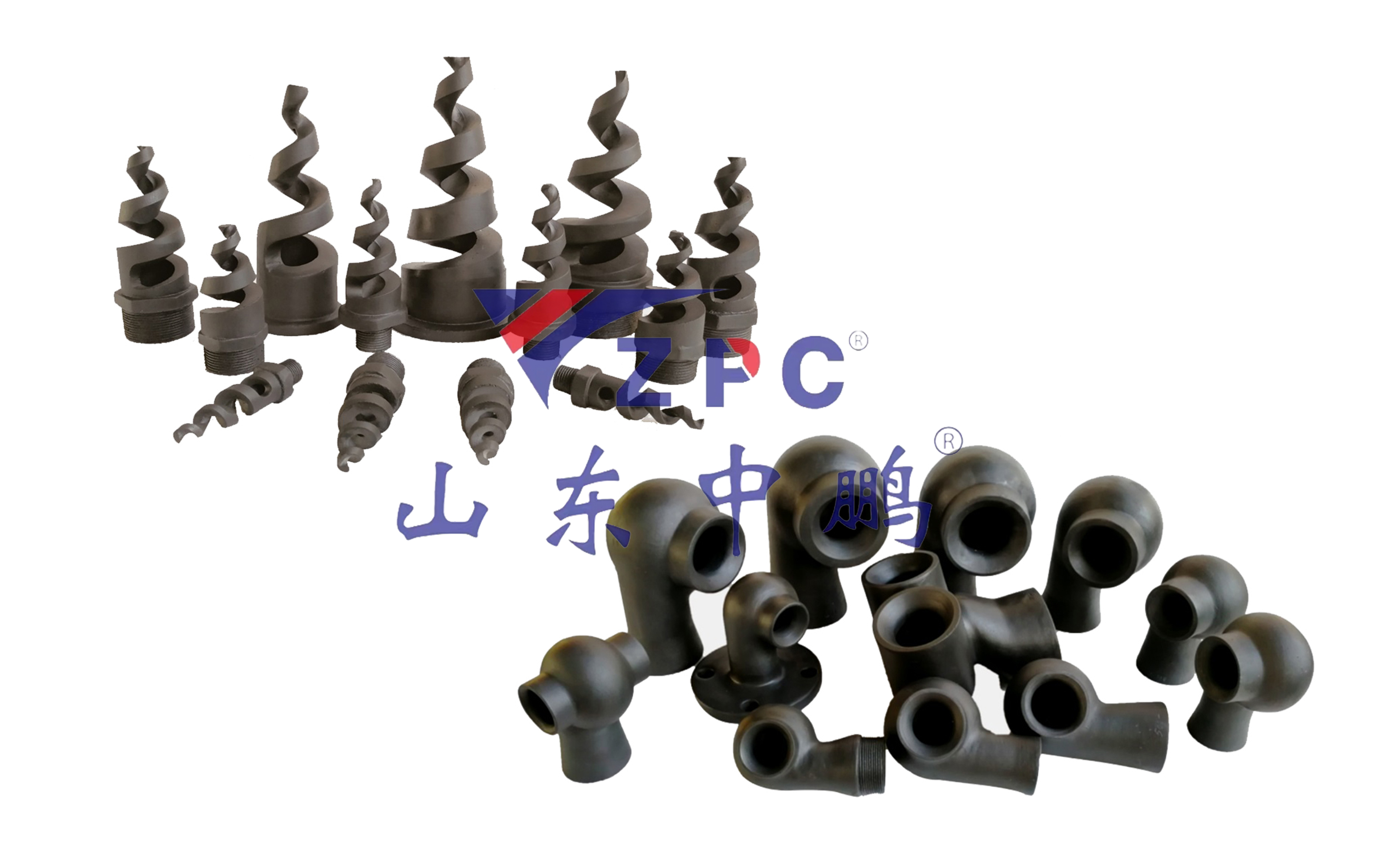

Raws li lub hauv paus tseem ceeb ntawm cov txheej txheem ntxuav roj flue niaj hnub no,silicon carbide FGD NozzlesUa lub luag haujlwm tseem ceeb hauv kev lag luam xws li lub zog thermal thiab metallurgy. Lub silicon carbide ceramic nozzle no tau daws qhov teeb meem ntawm cov hlau nozzles ib txwm muaj nyob rau hauv kev xeb muaj zog thiab kev hnav siab los ntawm kev tsim qauv tshiab thiab kev tshawb fawb txog cov khoom siv, ua kom zoo dua qub desulfurization efficiency.

1, Cov khoom siv tsim lub hauv paus rau kev ua tau zoo

Lub zog ntawm Mohssilicon carbide ceramicsncav cuag 9.2, thib ob tsuas yog pob zeb diamond, thiab nws qhov tawg toughness yog peb zaug ntawm alumina ceramics. Cov qauv siv lead ua ke no muab cov khoom siv nrog kev tiv thaiv zoo heev, thiab nyob rau hauv qhov cuam tshuam ntawm cov slurry ceev ceev uas muaj gypsum crystals (nqi ntws txog 12m / s), qhov hnav ntawm qhov chaw tsuas yog 1/20 ntawm cov hlau nozzles. Hauv ib puag ncig acid-base alternating nrog tus nqi pH ntawm 4-10, qhov kev tiv thaiv corrosion ntawm silicon carbide yog tsawg dua 0.01mm / xyoo, uas zoo dua li 0.5mm / xyoo ntawm 316L stainless hlau.

Tus coefficient ntawm thermal expansion ntawm cov khoom siv (4.0 × 10 ⁻⁶/℃) yog ze rau cov hlau, thiab nws tseem tuaj yeem tswj tau qhov ruaj khov ntawm cov qauv hauv qab qhov kub sib txawv ntawm 150 ℃. Silicon carbide ceramics npaj los ntawm cov txheej txheem sintering muaj qhov ceev ntawm ntau dua 98% thiab porosity tsawg dua 0.5%, zoo tiv thaiv kev puas tsuaj ntawm cov qauv los ntawm kev nkag mus rau hauv nruab nrab.

2, Precision atomization mechanism thiab flow field control

Lubsilicon carbide kauv nozzleua rau qhov ceev ntawm cov slurry nce ntxiv, thiab nrog qhov qhib qhov tseeb, nws rhuav cov limestone slurry ua cov tee me me thiab sib xws. Lub hollow conical spray teb npog uas tsim los ntawm cov qauv no yog loj heev, thiab lub sijhawm nyob ntawm cov tee dej hauv lub pej thuam tau ntev txog 2-3 vib nas this, siab dua 40% dua li ntawm cov nozzles ib txwm muaj.

3. Kev sib phim ntawm lub kaw lus thiab kev txhim kho engineering

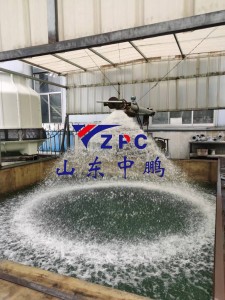

Hauv ib lub pej thuam tsuag ib txwm muaj,silicon carbide FGD nozzlessiv cov txheej txheem chessboard, nrog qhov sib nrug ntawm 1.2-1.5 npaug ntawm lub taub hau tsuag, tsim 3-5 txheej ntawm kev sib tshooj. Qhov kev npaj no ua kom ntseeg tau tias qhov kev npog ntawm lub pej thuam desulfurization ntau tshaj 200%, kom ntseeg tau tias muaj kev sib cuag txaus ntawm cov pa roj flue thiab cov slurry. Nrog rau qhov ntws ntawm lub pej thuam khoob ntawm 3-5 m / s, qhov poob siab ntawm lub kaw lus raug tswj hwm hauv qhov ntau ntawm 800-1200 Pa.

Cov ntaub ntawv ua haujlwm qhia tau hais tias qhov ua tau zoo ntawm desulfurization ntawm FGD system siv silicon carbide nozzles tseem ruaj khov ntawm ntau dua 97.5%, thiab cov dej noo ntawm gypsum by-products raug txo kom qis dua 10%. Lub voj voog txij nkawm khoom siv tau txuas ntxiv los ntawm 3 lub hlis rau cov hlau nozzles mus rau 3 xyoos, thiab tus nqi ntawm cov khoom seem hloov tau txo qis 70%.

Daim ntawv thov ntawm qhov noFGD nozzlecim ib qho kev dhia los ntawm cov khoom siv tiv thaiv ib puag ncig dav dav mus rau qhov tseeb. Nrog rau kev loj hlob ntawm 3D luam ntawv ceramic thev naus laus zis, kev tsim qauv topology optimization ntawm cov qauv ntws yuav raug ua tiav yav tom ntej, uas tuaj yeem txhim kho kev ua haujlwm atomization ntxiv los ntawm 15-20% thiab txhawb nqa ultra-low emission technology kom nkag mus rau theem tshiab ntawm kev txhim kho.

Lub sijhawm tshaj tawm: Lub Peb Hlis-24-2025