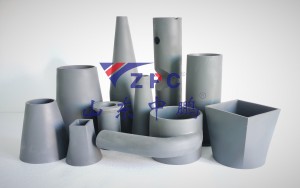

Iiplastiki ze-silicon carbide ceramic

I-silicon carbide engagugiyo

Iimpawu zoYilo lweeLiners ezimelana nokunxitywa zeSilicon Carbide (SiC):

(1)Uyilo lweNdlela yokuHamba eLungelelanisiweyo

Umgca ogudileyo nolungeleleneyo ukusuka ekungeneni ukuya ekuphumeni unciphisa ukumelana nokuhamba kwamanzi, nto leyo eyenza ii-SiC liners zilungele ukusetyenziswa kwemizi-mveliso eyahlukeneyo.

(2) Ukwenziwa kwe-Atomization okuPhambili

I-MechanismLiquids iguqulwa ibe ngamathontsi amancinci ngokungqubana okubonakalayo okuncitshiswa kancinci kancinci kwemiphezulu ye-SiC liner, okuqinisekisa ukusasazwa okufanayo kwe-spray.

(3)Ulwakhiwo oluncinci, olungenazimbobo

Umjelo wokuhamba othe ngqo nongenasiseko ususa izithintelo zangaphakathi, uphucula kakhulu ulwelo ngaphakathi komlinganiselo wemibhobho evalekileyo ngelixa uthintela ukuvaleka.

(4)Iindlela ezimbini zokutshiza ukuze kuphuculwe ukusebenza kakuhle

Ixhasa zombini iipateni zokutshiza ze-solid-cone kunye ne-hollow-cone, inikezela ngee-engile ezibanzi zokugubungela kunye nokusebenza okuchasene nokuvaleka kwemisebenzi yokusebenza kakuhle.

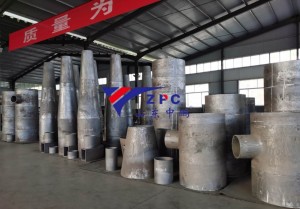

Iingenelo eziphambili xa kuthelekiswa nezinye izinto:

(1) Ukumelana nokunxiba okungalinganiyo

Ubunzima: Ii-SiC liners zinobunzima be-Mohs obuyi-9.5 (xa kuthelekiswa ne-8.0 yee-alumina ceramics, i-6.0 yentsimbi ene-chromium ephezulu), nto leyo ebenza bakwazi ukumelana nokuguguleka okukhulu kwi-slurry yemigodi, uthuthu lwamalahle, kunye nomgubo wesinyithi.

Ubude bexesha: Ubomi benkonzo budlula izinto zemveli ezi-5–10× (umz. ii-raber okanye ii-polyurethane liners) kwizicelo ezinefuthe elikhulu ezifana nee-ball mills okanye ii-slurry pumps.

(2)Ukugqwala kunye nokungangeni kweekhemikhali

Ukumelana ne-Acid/Alkali: Iyamelana ne-acid e-sulfuric exineneyo (98%), i-sodium hydroxide (50%), kunye neetyuwa ezinyibilikisiweyo (umz. i-NaCl-KCl kwi-800°C), ngelixa iintsimbi zibola ngokukhawuleza kwaye iipolymers zibola.

Akukho kungcoliswa: Umphezulu ongaphenduliyo uqinisekisa ubunyulu kwimveliso yebhetri ye-semiconductor okanye ye-lithium, ngokungafaniyo nee-liners zentsimbi ezithambekele ekutsaleni kwe-ion.

(3) Uzinzo olugqithisileyo lobushushu

Ukumelana nobushushu: Isebenza rhoqo kwi-1,600°C (xa kuthelekiswa nomda we-alumina we-1,200°C) ngokwandiswa okuncinci kobushushu (CTE: 4.0×10⁻⁶/℃), ithintela ukuqhekeka kwii-oven okanye kwii-oven zokunyibilikisa.

Ukumelana Nokushukuma Kobushushu: Igcina ulwakhiwo luqinile phantsi kotshintsho olukhawulezileyo lobushushu (umz. ukucima ukusuka kwi-1,000°C ukuya kubushushu begumbi), ngokungafaniyo neeseramikhi ezibuthathaka.

(4) Ukusebenza kakuhle kwamandla kunye noyilo olulula

Ukungqubana okuphantsi: Umphezulu we-SiC ocoliweyo (Ra <0.1 μm) unciphisa ukumelana nolwelo ngama-30–50% xa kuthelekiswa nee-liners zentsimbi ezingacacanga, nto leyo enciphisa iindleko zamandla okupompa.

Ukonga Ubunzima: Ubuninzi be-3.1 g/cm³ (xa kuthelekiswa ne-7.8 g/cm³ yentsimbi) kwenza kube lula ukufakela kwaye kuxhasa izixhobo ezikhaphukhaphu kwiiyunithi zokucubungula izinto ezisemoyeni okanye eziphathwayo.

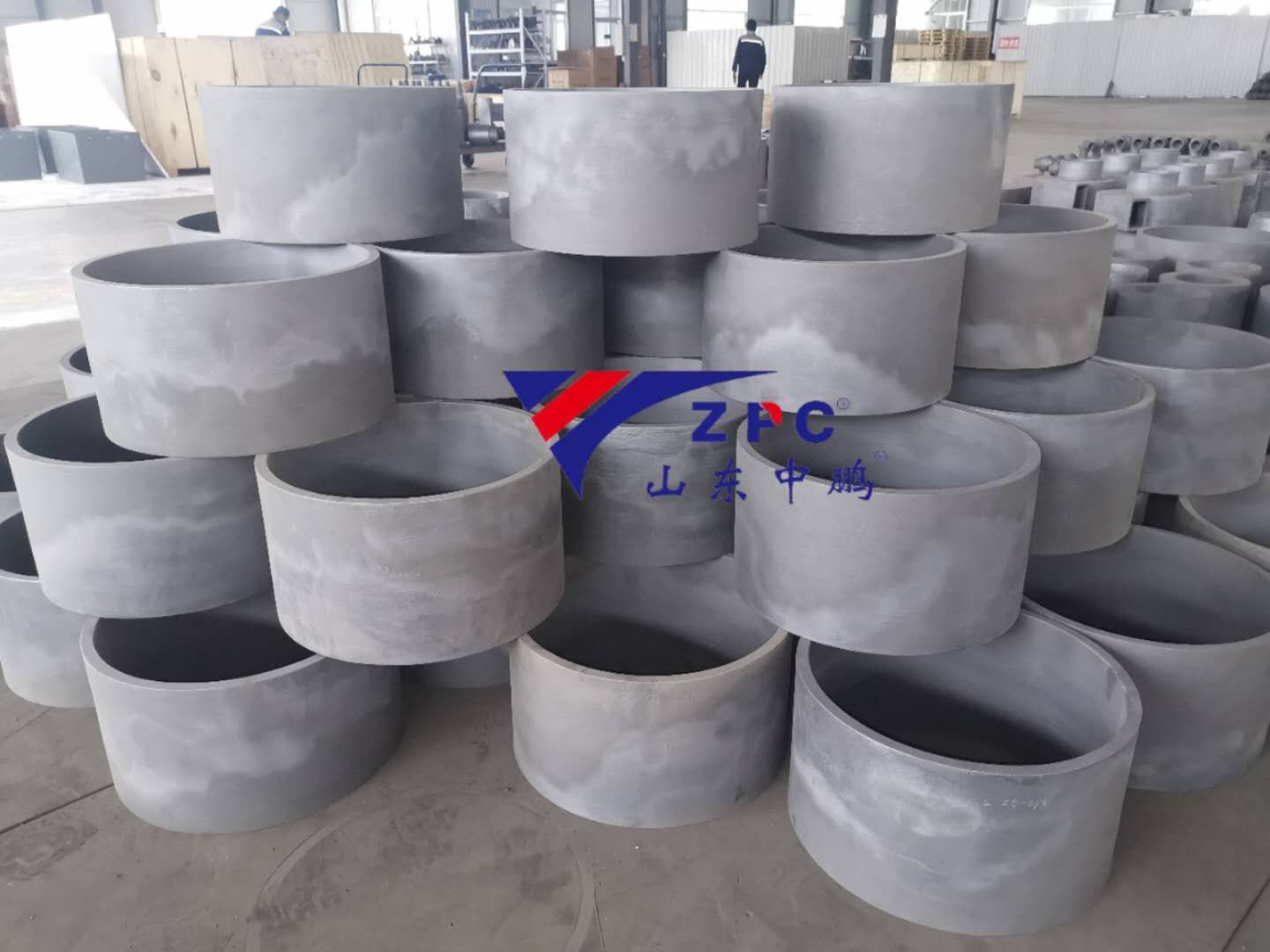

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.