Zitsulo za ceramic za silicon carbide

Chipinda cholimba cholimba cha silicon carbide

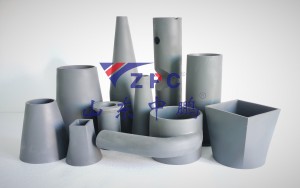

Kapangidwe ka Ma Liners Osavala a Silicon Carbide (SiC):

(1)Kapangidwe ka Njira Yoyenda Mosavuta

Mawonekedwe osalala komanso osavuta kuyambira polowera kupita potulukira amachepetsa kukana kwa madzi, zomwe zimapangitsa kuti ma SiC liners azitha kugwiritsidwa ntchito m'mafakitale osiyanasiyana.

(2) Kutulutsa kwapamwamba

Madzi amapangidwa kukhala madontho ang'onoang'ono kudzera mu kugundana kwa tangential komwe kumachepa pang'onopang'ono pamwamba pa SiC liner, kuonetsetsa kuti kufalikira kwa spray kuli kofanana.

(3) Kapangidwe Kakang'ono, Kopanda Kutsekeka

Njira yolunjika, yopanda pakati, imachotsa zopinga zamkati, ndikuwonjezera kuchuluka kwa madzi mkati mwa mapaipi otsekedwa pomwe imaletsa kutsekeka.

(4)Mauthenga Awiri Opopera Kuti Mugwire Bwino Ntchito

Imathandizira njira zopopera za solid-cone ndi hollow-cone, zomwe zimapereka ma angles ambiri ophimba komanso magwiridwe antchito oletsa kutsekeka kwa ntchito zogwira ntchito bwino kwambiri.

Ubwino waukulu poyerekeza ndi zipangizo zina:

(1) Kukana Kuvala Kosayerekezeka

Kulimba: Ma liners a SiC amafika pa kulimba kwa Mohs kwa 9.5 (mosiyana ndi 8.0 ya alumina ceramics, 6.0 ya chitsulo chapamwamba cha chromium), zomwe zimawathandiza kupirira kuwonongeka kwakukulu kwa matope a migodi, phulusa la malasha, ndi ufa wachitsulo.

Kutalika kwa nthawi: Nthawi yogwiritsira ntchito zinthu zakale imaposa 5–10× (monga rabara kapena polyurethane liners) m'magwiritsidwe ntchito amphamvu kwambiri monga ma ball mills kapena ma slurry pumps.

(2) Kudzikundikira ndi Kusagwira Ntchito kwa Mankhwala

Kukana kwa Asidi/Alkali: Kumalimbana ndi asidi wokhuthala wa sulfuric (98%), sodium hydroxide (50%), ndi mchere wosungunuka (monga NaCl-KCl pa 800°C), pomwe zitsulo zimawonongeka mwachangu ndipo ma polima amawonongeka.

Kusaipitsidwa konse: Malo osasinthika amatsimikizira kuyera kwa semiconductor kapena batire ya lithiamu, mosiyana ndi zitsulo zomwe zimakhala ndi ma ion leaching.

(3) Kukhazikika Kwambiri pa Kutentha

Kupirira Kutentha: Imagwira ntchito mosalekeza pa 1,600°C (motsutsana ndi malire a alumina a 1,200°C) ndi kutentha kochepa (CTE: 4.0×10⁻⁶/℃), kuteteza ming'alu m'mauvuni kapena ng'anjo zosungunulira.

Kukana Kutentha ndi Kutentha: Imasunga umphumphu wa kapangidwe kake pamene kutentha kusinthasintha mofulumira (monga kuzimitsa kuchokera pa 1,000°C mpaka kutentha kwa chipinda), mosiyana ndi zoumba zosweka.

(4) Kugwiritsa Ntchito Mphamvu Moyenera ndi Kapangidwe Kopepuka

Kukangana Kochepa: Malo opukutidwa a SiC (Ra <0.1 μm) amachepetsa kukana kwa madzi ndi 30–50% poyerekeza ndi zitsulo zopyapyala, zomwe zimachepetsa ndalama zopopera mphamvu.

Kuchepetsa Kulemera: Kuchuluka kwa 3.1 g/cm³ (motsutsana ndi 7.8 g/cm³ yachitsulo) kumathandiza kuyika mosavuta ndikuthandizira zida zopepuka m'mayunitsi opangira zinthu m'mlengalenga kapena m'magalimoto.

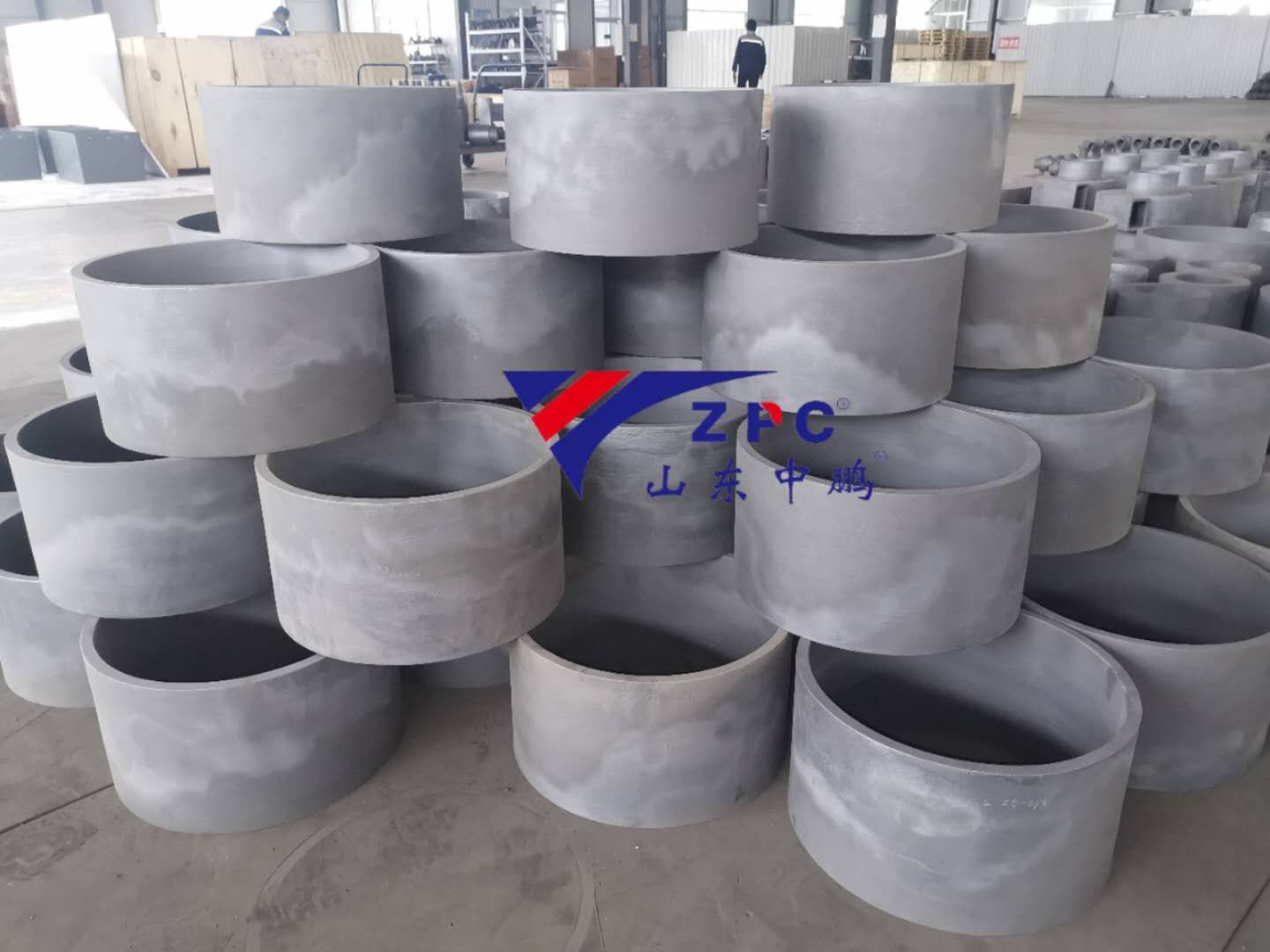

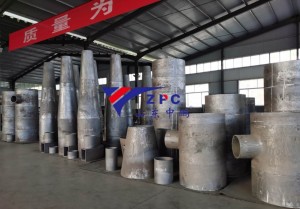

Shandong Zhongpeng Special Ceramics Co., Ltd ndi imodzi mwa njira zazikulu kwambiri zothetsera zinthu zatsopano za silicon carbide ceramic ku China. SiC technical ceramic: Kuuma kwa Moh ndi 9 (Kuuma kwa New Moh ndi 13), komwe kumalimbana bwino ndi kukokoloka ndi dzimbiri, kukana bwino kwambiri - kukana komanso kukana okosijeni. Moyo wa ntchito wa SiC ndi wautali nthawi 4 mpaka 5 kuposa 92% alumina. MOR ya RBSiC ndi nthawi 5 mpaka 7 kuposa ya SNBSC, ingagwiritsidwe ntchito pazinthu zovuta kwambiri. Njira yowerengera mawu ndi yachangu, kutumiza kumakhala monga momwe kunalonjezera ndipo khalidwe lake ndi lapamwamba kwambiri. Nthawi zonse timapitilizabe kutsutsa zolinga zathu ndikubwezera mitima yathu kwa anthu.