Zvishongo zvesimbi zvesilicon carbide

Silicon carbide inodzivirira kusakara

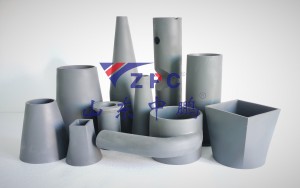

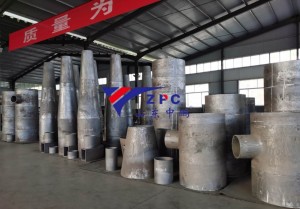

Zvimiro zveMagadzirirwo eSilicon Carbide (SiC) Wear-Resistant Liners:

(1) Dhizaini yeNzira Yekuyerera Yakarongeka

Kurongeka kwakapfava uye kwakarongeka kubva pakupinda nepakubuda kunoderedza kuramba kwemvura ichiyerera, zvichiita kuti SiC liners ikwanise kushandiswa mumaindasitiri akasiyana-siyana.

(2) Kugadziriswa Kwepamusoro

Mechanism Liquids inogadzirwa kuita madonhwe madiki kuburikidza nekusangana kwetangential nemativi eSiC liner anotetepa zvishoma nezvishoma, zvichiita kuti spray iparadzirwe zvakaenzana.

(3)Maumbirwo Akamanikana, Asina Kuvharika

Nzira yekuyerera isina chinhu inobvisa zvipingamupinyi zvemukati, ichiwedzera kuyerera kwemvura mukati memapaipi akavharirwa uku ichidzivirira kuvharika.

(4)Maitiro maviri epfapfaidzo ekuwedzera kushanda zvakanaka

Inotsigira mapatani ekupfapfaidza e solid-cone ne hollow-cone, ichipa makona akafara ekufukidza uye inodzivirira kuvhara kwekushanda kwepamusoro-soro.

Zvakanakira zvepakati zvichienzaniswa nezvimwe zvinhu:

(1) Kusapfeka Kusingaenzaniswi

Kuomarara: SiC liners dzine kuomarara kweMohs kwe9.5 (zvichienzaniswa ne8.0 yealumina ceramics, 6.0 yesimbi ine chromium yakawanda), zvichiita kuti dzikwanise kutsungirira kusakara kwakanyanya mumigodhi, dota remarasha, uye upfu hwesimbi.

Hurefu hwenguva: Hupenyu hwebasa hunodarika 5–10× zvinhu zvechinyakare (semuenzaniso rabha kana polyurethane liners) mumashandisirwo ane simba guru senge mabhora kana mapombi eslurry.

(2)Kuora uye Kusashanda kweMakemikari

Kuramba kweAcid/Alkali: Kunodzivirira sulfuric acid yakawanda (98%), sodium hydroxide (50%), uye munyu wakanyungudutswa (semuenzaniso NaCl-KCl pa800°C), nepo simbi dzichikurumidza kuora uye mapolymer achiora.

Kusasvibiswa: Nzvimbo isingashande zvakanaka inovimbisa kuchena mukugadzirwa kwemabhatiri e semiconductor kana lithium, kusiyana nema liner esimbi anowanzo kanganiswa ne ion leaching.

(3) Kugadzikana Kwekupisa Kwakanyanya

Kutsungirira Kupisa: Inoshanda nguva dzose pa1,600°C (zvichienzaniswa nemuganhu we1,200°C wealumina) nekuwedzera kushoma kwekupisa (CTE: 4.0×10⁻⁶/℃), ichidzivirira kutsemuka mumakiln kana maoven ekunyungudutsa.

Kuramba Kupisa Nekuvhunduka: Inochengetedza chimiro chayo kana tembiricha ikachinja-chinja nekukurumidza (semuenzaniso kudzima kubva pa1,000°C kusvika patembiricha yemukamuri), kusiyana neceramics dzakapfava.

(4) Kushanda Nesimba Uye Dhizaini Yakareruka

Kukweshana Kwakaderera: Nzvimbo yakakweshwa yeSiC (Ra <0.1 μm) inoderedza kuramba kwemvura ne30–50% zvichienzaniswa nesimbi dzakaoma, zvichideredza mari yekushandisa pakupomba.

Kuderedza Huremu: Huremu hwe3.1 g/cm³ (zvichienzaniswa ne7.8 g/cm³ yesimbi) hunoita kuti zvive nyore kuisa uye hunotsigira michina yakareruka muzvishandiso zvemuchadenga kana zvekufambisa.

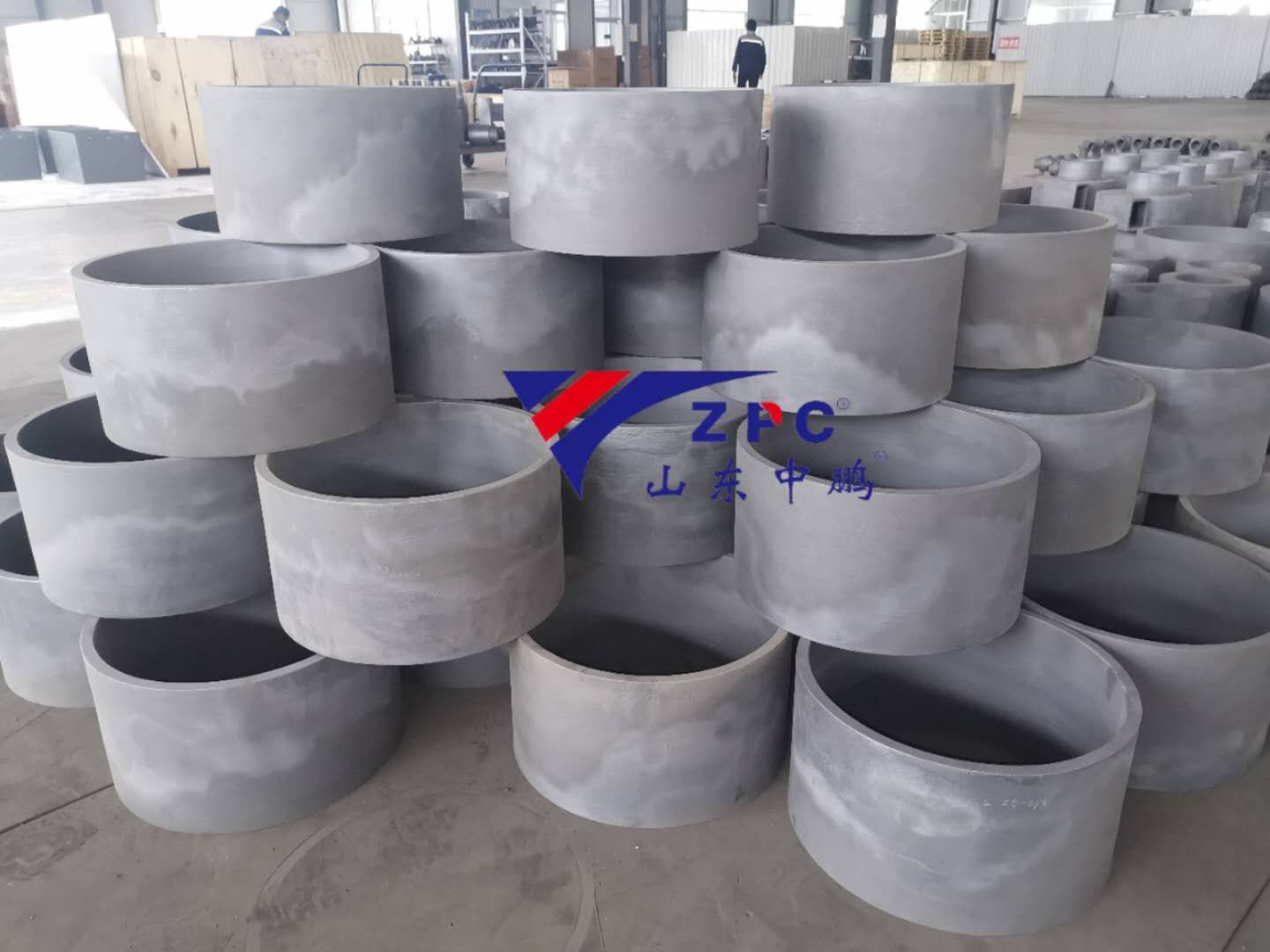

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yemhando huru dzesilicon carbide ceramic itsva muChina. SiC technical ceramic: Kuomarara kwaMoh kwa9 (Kuomarara kwaNew Moh kwa13), nekusimba kwakanaka pakukukurwa nekuora, kusimba kwakanaka - kusimba uye kudzivirira oxidation. Hupenyu hwebasa rechigadzirwa cheSiC hwakareba ka4 kusvika ka5 kupfuura 92% alumina material. MOR yeRBSiC yakapetwa ka5 kusvika ka7 kupfuura SNBSC, inogona kushandiswa kune mamwe maumbirwo akaomarara. Maitiro ekukosha kwemashoko anokurumidza, kuendesa kwacho kwakaitwa sezvakavimbiswa uye mhando yacho haina kukosha. Tinogara tichiramba tichipikisa zvinangwa zvedu uye tinopa moyo yedu kunharaunda.