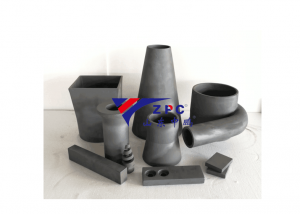

Iimpumlo ze-FGD ze-silicon carbide

Ii-nozzles ze-silicon carbide FGD zizinto ezibalulekileyo kwizityalo zamandla obushushu, kwiibhoyila ezinkulu, nakwizixhobo zokususa i-sulphurization kunye nokuqokelela uthuli.

Ezi mveliso zithandwa kakhulu ngamashishini ahlukeneyo, ngenxa yeempawu zazo, ezinje ngokumelana nokugqwala, ubulukhuni obuphezulu, ukusebenza okuzinzileyo njalo njalo.

IiNozzles zokufunxa igesi ephuma kwiFlue Gas Desulfurization (FGD)

Ukususwa kwee-sulfur oxides, ezibizwa ngokuba yi-SOx, kwiigesi zokukhupha umoya kusetyenziswa i-alkali reagent, njenge-limestone slurry emanzi.

Xa amafutha efosili esetyenziswa kwiinkqubo zokutsha ukuqhuba iibhoyila, ii-oven, okanye ezinye izixhobo, anokukwazi ukukhupha i-SO2 okanye i-SO3 njengenxalenye yegesi ephumayo. Ezi sulfur oxides zisabela ngokulula nezinye izinto ukuze zenze i-compound enobungozi efana ne-sulfuric acid kwaye zinokuba nefuthe elibi kwimpilo yabantu nakwindalo esingqongileyo. Ngenxa yezi ziphumo zinokwenzeka, ulawulo lwale compound kwiigesi ze-flue luyinxalenye ebalulekileyo yezityalo zamandla ezisebenzisa amalahle kunye nezinye izicelo zoshishino.

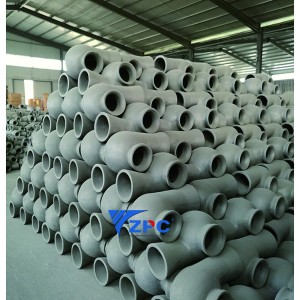

Ngenxa yokukhukuliseka, ukuvalwa, kunye nokwakheka, enye yezona nkqubo zithembekileyo zokulawula le nkunkuma yinkqubo ye-open-tower wet flue gas desulfurization (FGD) esebenzisa ilitye lekalika, ilime emanzi, amanzi olwandle, okanye esinye isisombululo se-alkaline. Ii-spray nozzles ziyakwazi ukusasaza ezi slurry ngokufanelekileyo nangokuthembekileyo kwiinqaba zokufunxa. Ngokwenza iipateni ezifanayo zamaconsi anobukhulu obufanelekileyo, ezi nozzles ziyakwazi ukudala ngokufanelekileyo indawo yomphezulu efunekayo ukuze kufunxwe ngokufanelekileyo ngelixa zinciphisa ukufakwa kwesisombululo sokukhuhla kwigesi ye-flue.

IiNozzles zeSiC FGD Absorber:

A: IiNozzles zeTangential zeCone ezingenanto

B: IiNozzles ezipheleleyo zeCone Tangential

C: IiNozzles zeCone ezipheleleyo

D: IiNozzles zePulse

E: IiNozzles ze-SMP

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.