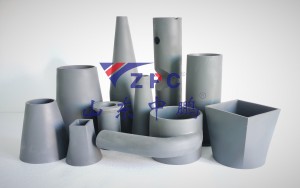

Ama-liners e-ceramic e-silicon carbide

Ulwelwesi olumelana nokuguguleka lwe-silicon carbide

Izici Zokuklama Zama-Liner Amelana Nokugqokwa e-Silicon Carbide (SiC):

(1)Umklamo Wendlela Yokugeleza Eqondisiwe

Ukwakheka okubushelelezi nokulula kusuka ekungeneni komoya kuya ekuphumeni kunciphisa ukumelana nokugeleza kwamanzi, okwenza ama-SiC liners avumelane nezinhlelo zokusebenza ezahlukahlukene zezimboni.

(2)Ukwenziwa Okuthuthukisiwe Kwe-Atomization

I-MechanismUketshezi luguqulwa lube amaconsi amancane ngokushayisana okubonakalayo okuncishiswa kancane kancane kwe-SiC liner, okuqinisekisa ukusatshalaliswa okufanayo kwesifutho.

(3)Isakhiwo Esincane, Esingenawo Ama-Clog

Isiteshi sokugeleza esiqondile nesingenamgogodla sisusa izithiyo zangaphakathi, sandise uketshezi olungena ngaphakathi kobukhulu bepayipi elivalekile ngenkathi sivimbela ukuvaleka.

(4)Izindlela Zokufafaza Ezimbili Zokusebenza Kahle Okuthuthukisiwe

Isekela amaphethini okufafaza anekhoni eliqinile kanye nekhoni elingenalutho, inikeza ama-engeli abanzi okumboza kanye nokusebenza okulwa nokuvaleka kwemisebenzi yokusebenza kahle kakhulu.

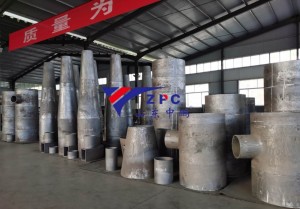

Izinzuzo eziyinhloko uma kuqhathaniswa nezinye izinto:

(1) Ukumelana Nokugqokwa Okungalingani

Ukuqina: Ama-SiC liners afinyelela ubulukhuni be-Mohs obungu-9.5 (uma kuqhathaniswa no-8.0 we-alumina ceramics, u-6.0 wensimbi ene-chromium ephezulu), okwenza akwazi ukumelana nokuguguleka okukhulu kwe-slurry yezimayini, umlotha wamalahle, kanye nempuphu yensimbi.

Ubude besikhathi: Impilo yesevisi idlula izinto zendabuko ezingu-5–10× (isb. irabha noma i-polyurethane liner) ezisetshenziswayo ezinomthelela omkhulu njengezigayo zebhola noma amaphampu e-slurry.

(2)Ukugqwala kanye nokungangeni kahle kwamakhemikhali

Ukumelana ne-Acid/Alkali: Kumelana ne-asidi ye-sulfuric egxilile (98%), i-sodium hydroxide (50%), kanye nosawoti oncibilikisiwe (isb. i-NaCl-KCl ku-800°C), kuyilapho izinsimbi zibola ngokushesha futhi ama-polymers awonakala.

Ukungcola Okungaphenduki: Indawo engaphenduli iqinisekisa ubumsulwa ekukhiqizweni kwebhethri le-semiconductor noma le-lithium, ngokungafani nama-liners ensimbi athambekele ekuleheni kwe-ion.

(3) Ukuqina Kokushisa Okukhulu

Ukuqina Kokushisa: Isebenza njalo ku-1,600°C (uma kuqhathaniswa nomkhawulo we-alumina ongu-1,200°C) ngokwandiswa okuncane kokushisa (CTE: 4.0×10⁻⁶/℃), ivimbela ukuqhekeka kuma-oven noma kuma-oven okuncibilikisa.

Ukumelana Nokushaqeka Okushisayo: Kugcina ubuqotho besakhiwo ngaphansi kokushintshashintsha kwezinga lokushisa okusheshayo (isb. ukucima kusuka ku-1,000°C kuya ekushiseni kwegumbi), ngokungafani nezitsha zobumba ezibuthakathaka.

(4) Ukusebenza Kahle Kwamandla Nomklamo Olula

Ukungqubuzana Okuphansi: Ubuso be-SiC obucwebezelayo (Ra <0.1 μm) kunciphisa ukumelana koketshezi ngo-30–50% uma kuqhathaniswa nama-liners ensimbi aqinile, okunciphisa izindleko zamandla okupompa.

Ukonga Isisindo: Ubuningi obungu-3.1 g/cm³ (uma kuqhathaniswa no-7.8 g/cm³ wensimbi) kwenza kube lula ukufakwa futhi kusekela imishini elula kumayunithi okucubungula ezindiza noma eselula.

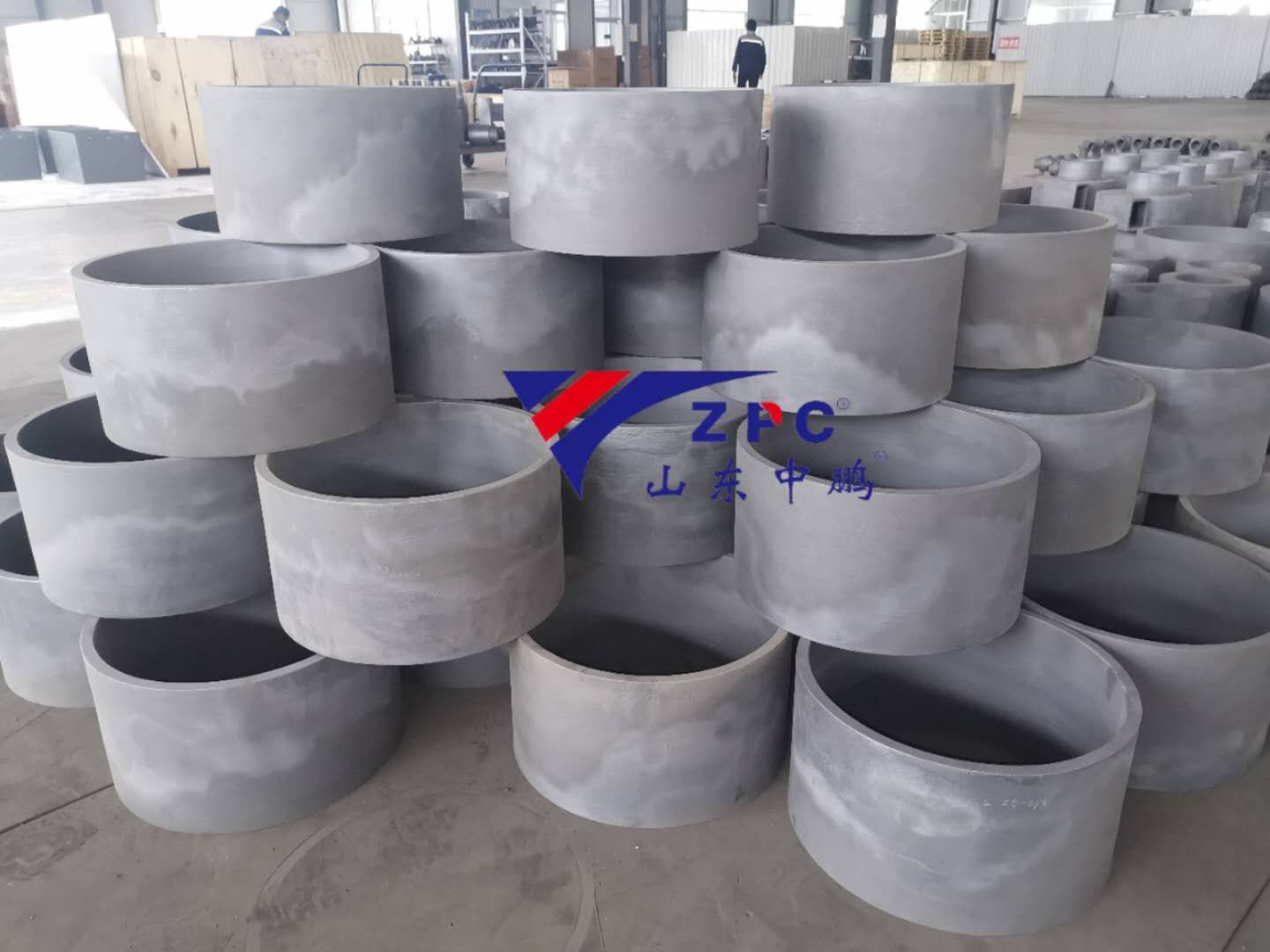

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingenye yezixazululo ezinkulu zezinto ezintsha ze-silicon carbide ceramic eShayina. I-SiC technical ceramic: Ubulukhuni bukaMoh buyi-9 (ubulukhuni bukaMoh obuyi-13), bunokumelana okuhle kakhulu nokuguguleka nokugqwala, ukumelana okuhle kakhulu - ukumelana nokugqwala kanye nokulwa nokubola. Impilo yesevisi yomkhiqizo we-SiC ide ngokuphindwe ka-4 kuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 kuya ku-7 kune-SNBSC, ingasetshenziswa ezimweni eziyinkimbinkimbi kakhulu. Inqubo yokucaphuna iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ayilingani. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisela izinhliziyo zethu emphakathini.