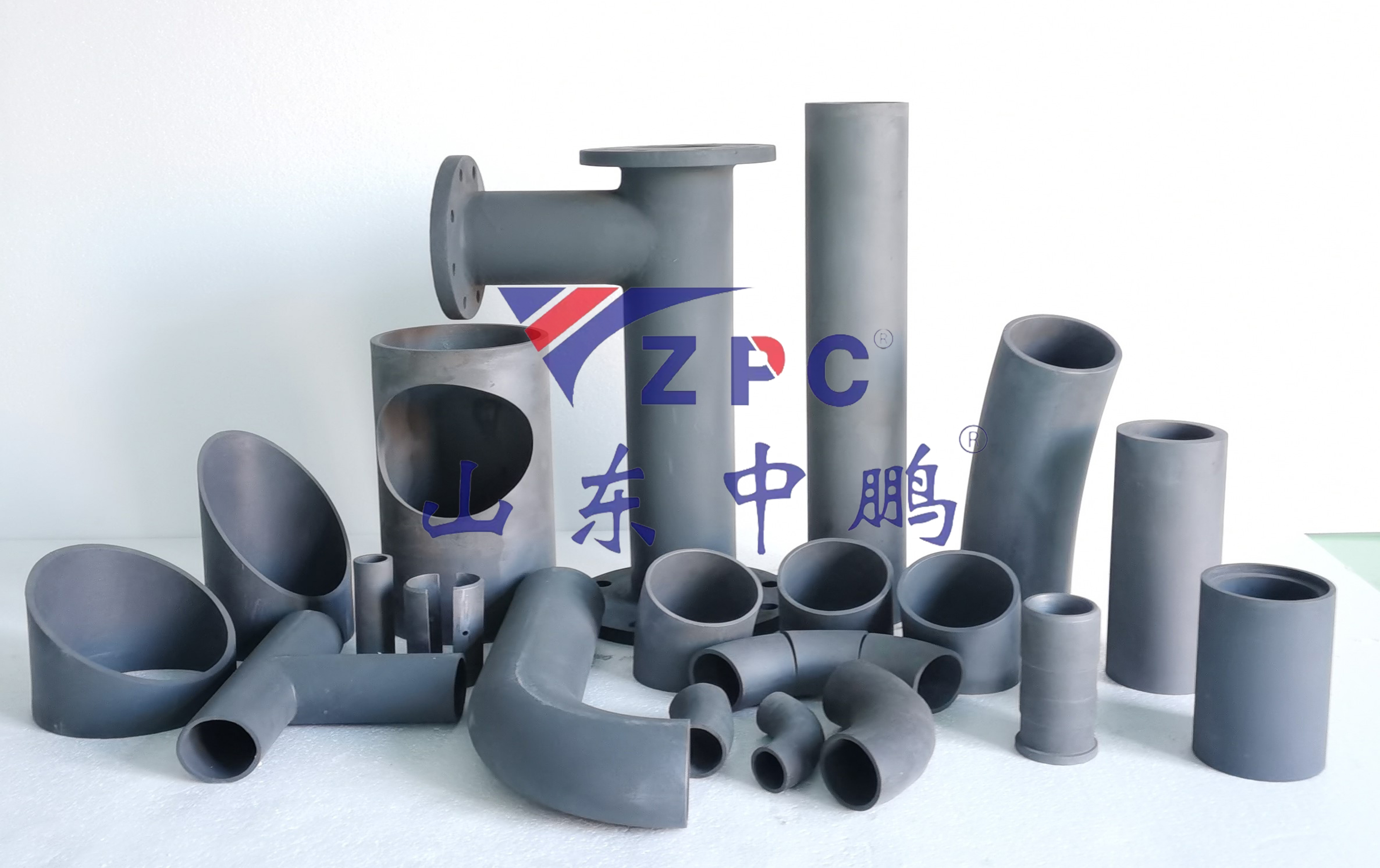

Umbhobho onganyangekiyo ogqunywe nge-silicon carbide ceramic

Iipayipi ezingagugiyo ze-silicon carbide ziipayipi ezenziwe kakhulu nge-silicon carbide kwaye zisetyenziswa kakhulu kwiindawo ezahlukeneyo. Ukhuphiswano lwayo oluphambili lulandelayo:

(1) Uguquko lobomi

Xa kuthuthwa izinto ezirhabaxa ezifana nodaka kunye nothuthu lwamalahle, ixesha lokuphila liphindwe kalishumi kunelesinyithi, nto leyo enciphisa ukutshintshwa rhoqo kunye nokulahleka kwexesha lokungasebenzi.

(2) Iimeko zokusebenza ezigqithisileyo zixhaphakile

Ukusebenza okuzinzileyo ukusuka kwi -50 ℃ ukuya kwi-1600 ℃, kunye nokumelana nobushushu bokuqhekeka, kufanelekile kwiimeko zobushushu obuphezulu ezifana ne-metallurgy kunye neshishini leekhemikhali.

(3) Ukusetyenziswa okuninzi kwento enye

Sombulula iingxaki ezine eziphambili zokuguguleka, ukugqwala, ubushushu obuphezulu, kunye nokuthintela ukuqhuma ngaxeshanye.

(4) Ilula kwaye igcina amandla

Uyilo olulula lunciphisa iindleko zokuhamba kunye nokufakela, kwaye i-coefficient ephantsi yokungqubana inciphisa ukusetyenziswa kwamandla okupompa.

Inzuzo yokutyumza yemibhobho ye-silicon carbide xa ithelekiswa nezixhobo zemveli:

| Ubungakanani bokusebenza | Umbhobho we-silicon carbide | Iipayipi zesinyithi/zeplastiki |

| Ukumelana nokunxiba | Ukuqina yi-2800HV (ngokuphindwe kahlanu kunentsimbi), ubomi bayo bude ngokuphindwe kalishumi kunemibhobho engeyoyesinyithi | Isinyithi sidla ngokuguguleka, ngelixa iplastiki inobunzima obuphantsi (PE<1 HV) |

| Ubushushu obuphezulu ukuxhathisa | Iyamelana namaqondo obushushu aphezulu e-1600 ℃ kunye noxinzelelo lobushushu (i-coefficient yokwandiswa kobushushu yi-4 × 10 ⁻⁶/℃) | Intsimbi engagqwaliyo ithambekele ekungcolisweni kobushushu xa ishushu kakhulu, ngelixa iiplastiki zinokumelana nobushushu obungaphantsi kwama-80 ℃ |

| Ukumelana nokugqwala | Ayimelani nee-asidi ezinamandla (i-asidi ye-sulfuric exineneyo), iziseko eziqinileyo, kunye nokubola kwesinyithi esinyibilikisiweyo | Intsimbi engagqwaliyo ifumana umhlwa xa ivezwe kwii-ion ze-chloride, ngelixa iplastiki inokumelana okuncinci kweekhemikhali |

| Ilula | Ubuninzi be-3.0~3.14 g/cm³ (ikhaphukhaphu engama-60% kunentsimbi) | Iipayipi zesinyithi zinkulu kwaye zibiza kakhulu ukufakelwa kwazo |

| Ukwandiswa kokusebenza | Ucoceko oluchasene ne-static (ukuqhuba okubuthathaka), kunye ne-semiconductor grade | Iintsimbi zifuna unyango olongezelelweyo lokuthintela ukuqhuma, ngelixa iiplastiki zinomngcipheko wokungcola |

Ngamafutshane, akukho sisombululo sithile seepayipi ze-silicon carbide xa kuthuthwa izinto ezibolayo nezinganyangekiyo ezifana ne-asidi slurry kunye nothuthu lwegesi olushushu kakhulu.

Ukuba unemibuzo, nceda ukhululeke ukunxibelelana nathi nangaliphi na ixesha.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.