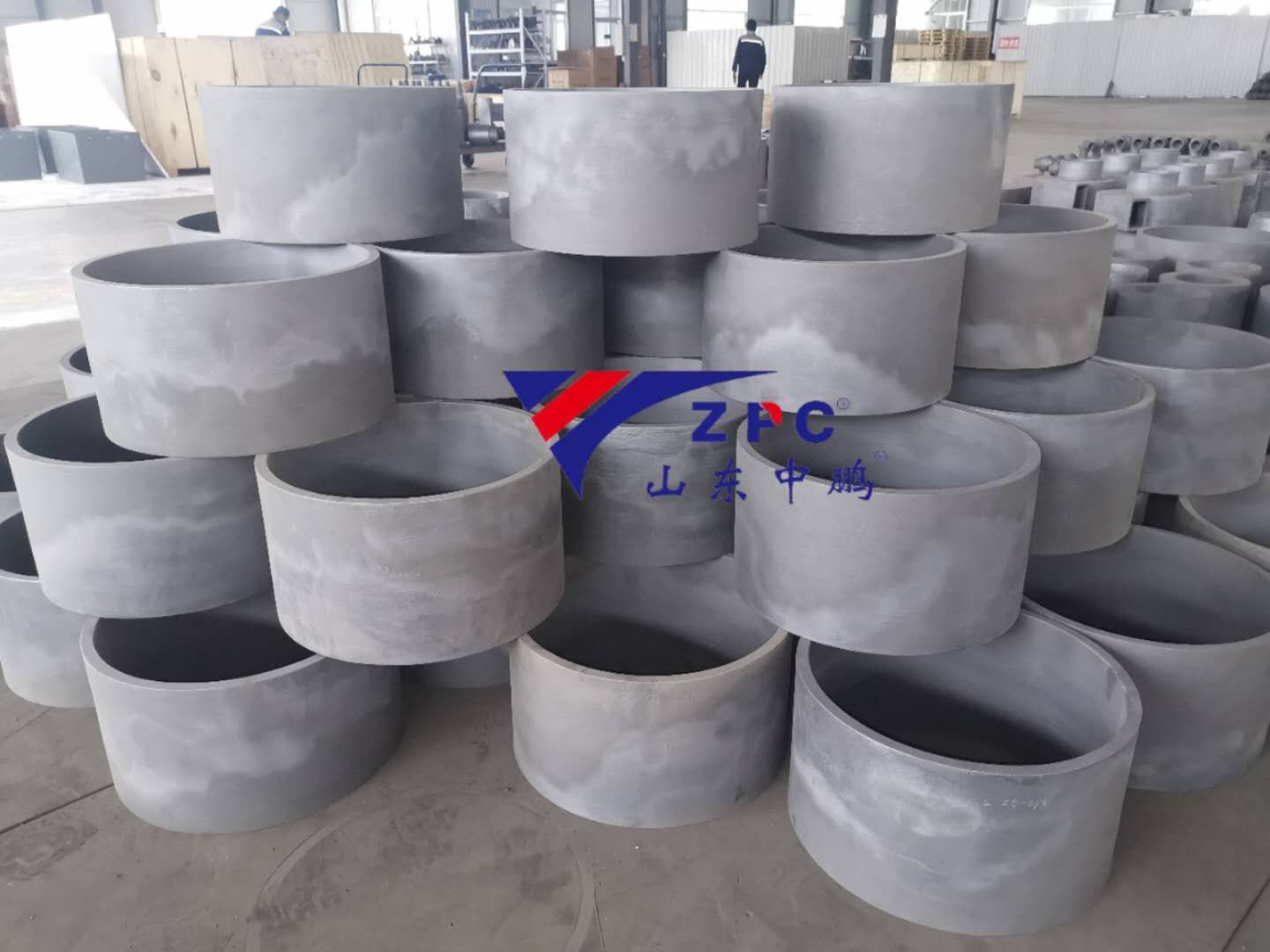

Layin yumbu na silicon carbide

Rufin da ke jure wa lalacewa na silicon carbide

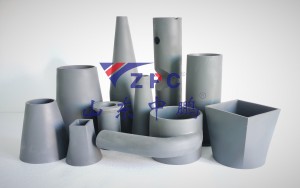

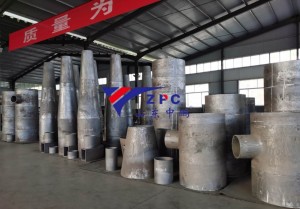

Siffofin Zane na Layukan Silicon Carbide (SiC) Masu Juriya da Lalacewa:

(1) Tsarin Hanyar Gudawa Mai Sauƙi

Tsarin da ya dace da kuma sassauƙa daga shiga zuwa fita yana rage juriyar kwarara, wanda hakan ke sa layukan SiC su zama masu dacewa da aikace-aikacen masana'antu daban-daban.

(2) Ingantaccen Atomization

Tsarin Ruwa yana narkewa zuwa ƙananan ɗigon ruwa ta hanyar karo mai kama da juna tare da raguwar saman layin SiC mai kama da helical, yana tabbatar da rarraba feshi iri ɗaya.

(3) Tsarin da ba ya toshewa, mai ƙanƙantawa

Tashar kwarara mai madaidaiciya, mara tushe tana kawar da cikas na ciki, tana haɓaka yawan ruwa a cikin bututun da aka iyakance yayin da take hana toshewa.

(4) Hanyoyin fesawa guda biyu don Inganta Inganci

Yana tallafawa tsarin feshi mai ƙarfi da kuma mai ramin-kore, yana ba da kusurwoyi masu faɗi da kuma aikin hana toshewa don ayyukan da suka dace.

Babban fa'idodi idan aka kwatanta da sauran kayan:

(1) Juriyar Sakawa Mara Daidaita

Taurin kai: Layin SiC sun kai taurin Mohs na 9.5 (idan aka kwatanta da 8.0 ga tukwanen alumina, 6.0 ga ƙarfe mai yawan chromium), wanda hakan ke ba su damar jure wa lalacewar da ke tattare da hakar ma'adinai, tokar kwal, da foda na ƙarfe.

Tsawon Rai: Rayuwar sabis ta wuce kayan gargajiya na 5-10× (misali roba ko polyurethane liners) a cikin aikace-aikacen da ke da tasiri sosai kamar injinan ball ko famfunan slurry.

(2) Tsatsa da Rashin Daidaito a Sinadarai

Juriyar Acid/Alkali: Yana jurewa sinadarin sulfuric mai ƙarfi (98%), sodium hydroxide (50%), da gishirin da aka narkar (misali NaCl-KCl a 800°C), yayin da ƙarfe ke narkewa da sauri kuma polymers ke lalacewa.

Gurɓataccen abu: Ba a samar da sinadarin da ke hana gurɓatawa ba, wanda ke tabbatar da tsarki a samar da batirin semiconductor ko lithium, sabanin ƙarfe masu laushi waɗanda ke iya haifar da ion.

(3) Tsayin Zafi Mai Tsanani

Juriyar Zafi: Yana aiki akai-akai a zafin 1,600°C (idan aka kwatanta da iyakar alumina ta 1,200°C) tare da ƙarancin faɗaɗa zafi (CTE: 4.0×10⁻⁶/℃), yana hana fashewa a cikin murhun wuta ko tanderun narke.

Juriyar Girgizar Zafi: Yana kiyaye mutuncin tsarin a ƙarƙashin saurin canjin zafin jiki (misali kashewa daga 1,000°C zuwa zafin ɗaki), ba kamar yumbu masu rauni ba.

(4)Ingancin Makamashi da Tsarin Mai Sauƙi

Ƙaramin Gogayya: saman SiC mai gogewa (Ra <0.1 μm) yana rage juriyar ruwa da kashi 30-50% idan aka kwatanta da layin ƙarfe mai kauri, yana rage farashin makamashin famfo.

Tanadin Nauyi: Yawan 3.1 g/cm³ (idan aka kwatanta da 7.8 g/cm³ na ƙarfe) yana sauƙaƙa shigarwa kuma yana tallafawa kayan aiki masu sauƙi a cikin na'urorin sarrafa sararin samaniya ko na'urorin sarrafa hannu.

Kamfanin Shandong Zhongpeng Special Ceramics Co., Ltd yana ɗaya daga cikin manyan hanyoyin samar da sabbin kayan yumbu na silicon carbide a China. SiC technical yumbu: Taurin Moh shine 9 (taurin New Moh shine 13), tare da kyakkyawan juriya ga zaizayar ƙasa da tsatsa, kyakkyawan juriya - juriya da hana iskar shaka. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da kayan alumina 92%. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani da shi don siffofi masu rikitarwa. Tsarin ƙididdigewa yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da nasaba da komai. Kullum muna ci gaba da ƙalubalantar manufofinmu kuma muna mayar da zukatanmu ga al'umma.