umenzi wee-crucibles ze-silicon carbide kunye nee-saggers

Le mveliso ilungele ukusetyenziswa kwi-oven yemizi-mveliso, ukunyibilikisa, ukunyibilikisa kwaye isetyenziswa kuzo zonke iintlobo zeemveliso. Kwicandelo leekhemikhali, ukhuseleko lwepetroleum kunye nokusingqongileyo kunye noluhlu olubanzi lwezicelo.

1) Uzinzo lobushushu

2) ukumelana nokugqwala kweekhemikhali

3) Ubushushu obuphezulu (ukuya kuthi ga kwi-1650°)

4) Iyamelana nokunxila/ukubola/ukubola

5) Ukusebenza kakuhle kwamandla oomatshini

6) Ukucoca okanye ukukrola iindawo ezingaphantsi komhlaba ezinzima

7) Isetyenziselwa ukugaya, ukulepha, kunye nokusika isarha yentsimbi kunye nokuqhumisa okurhabaxa

| Ukwakhiwa kweeKhemikhali SIC >= | % | 90 | |

| Ubushushu beNkonzo obuphezulu. | ºC | 1400 | |

| Ukungaguquguquki >= | SK | 39 | |

| 2kg/cm2 Ukungabi namandla okurhabaxa phantsi komthwalo T2 >= | ºC | 1790 | |

| Ipropati yefiziksi | Imodulus yeRupturt kubushushu begumbi >= | kg/cm2 | 500 |

| Imodulus yokuqhekeka kwi-1400ºC >= | kg/cm2 | 550 | |

| Amandla oxinzelelo >= | kg/cm2 | 1300 | |

| Ukwandiswa kobushushu kwi-1000ºC | % | 0.42-0.48 | |

| Ukuqhekeka Okubonakalayo | % | ≤20 | |

| Unizi lolwapho kuyiwa khona | g/cm3 | 2.55-2.7 | |

| Ukuqhuba kwe-Thermal kwi-1000ºC | I-Kcal/m.hr.ºC | 13.5-14.5 | |

Inkcazo:

I-crucible yimbiza yeseramikhi esetyenziselwa ukubamba isinyithi ukuze sinyibilike esithandweni. Le yi-crucible esemgangathweni ophezulu, ekumgangatho wemizi-mveliso esetyenziswa lishishini lezinto zokubumba zorhwebo.

Oko Kukwenzayo:

Isixhobo sokunyibilikisa kufuneka sikwazi ukumelana nobushushu obugqithisileyo obufunyanwa kwiintsimbi ezinyibilikisayo. Izinto zokunyibilikisa kufuneka zibe nendawo yokunyibilikisa ephezulu kakhulu kuneyesinyithi esinyibilikisayo kwaye kufuneka sibe namandla amahle nokuba sishushu kakhulu.

Kunokwenzeka ukusebenzisa i-crucible yentsimbi eyenziwe ekhaya ukunyibilikisa iintsimbi ezifana ne-zinc kunye ne-aluminium, kuba ezi zintsimbi zinyibilika kubushushu obungaphantsi kakhulu kobentsimbi. Nangona kunjalo, ukukrwela (ukuqhekeka) komphezulu wangaphakathi we-crucible yentsimbi yingxaki. Esi sikali sinokungcolisa ukunyibilika kwaye sinciphise iindonga ze-crucible ngokukhawuleza. Ii-crucible zentsimbi ziya kusebenza ukuba usaqala kwaye awunangxaki nokujongana ne-crucible.

Izinto ezisetyenziswa kakhulu xa kusenziwa izinto ezisetyenziswa ekubumbeni yi-clay-graphite, kunye ne-carbon bonded silicon-carbide. Ezi zinto zinokumelana namaqondo obushushu aphezulu kumsebenzi oqhelekileyo wokwakha izinto. I-silicon carbide inenzuzo eyongezelelweyo yokuba yinto eqinileyo kakhulu.

IiClay Graphite Bilge Shape crucibles zethu zilinganiswe ngama-2750 °F (1510 °C). Ziza kuphatha i-zinc, i-aluminium, ibronze/ibronze, isilivere kunye nee-alloys zegolide. Umenzi uthi zingasetyenziselwa isinyithi esityhidiweyo. Zenziwe eMelika!

Iimilo eziQokelelweyo:

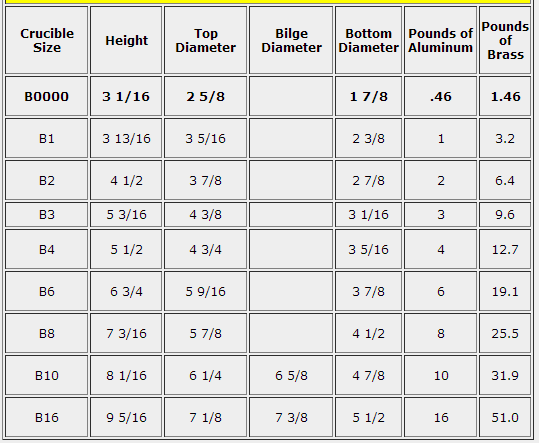

Isiqwenga esimile okwe-bilge (“B” Shape) simile okwe-wine barrel. Ubukhulu be-“bilge” bububanzi besiqwenga esimile okweyona ndawo ibanzi. Ukuba akukho bubanzi be-bilge bubonakalisiweyo, ke ububanzi obuphezulu bububanzi obuphezulu.

Umthetho oqhelekileyo uthi i-# ye-“bilge” crucible inika amandla ayo okusebenza aqikelelweyo kwiikhilogram ze-aluminiyam. Kwi-bronze okanye ibronze kusetyenziswa kathathu kune-crucible #. Umzekelo, i-#10 crucible ingaphatha malunga neekhilogram ezili-10 ze-aluminiyam kunye neekhilogram ezingama-30 zebronze.

Iicrucible zethu ezimile okwe-“B” zihlala zisetyenziswa ngabantu abathanda izinto zokuzonwabisa kunye nabantu abasebenzisa izixhobo zokudubula rhoqo. Ezi ziicrucible ezikumgangatho ophezulu, ezihlala ixesha elide zorhwebo.

Jonga iitheyibhile ezingezantsi ukuze ufumane ubungakanani obufanelekileyo bomsebenzi wakho.

Indlela Yokuyisebenzisa:

Zonke izixhobo zokubopha kufuneka ziphathwe ngezibambo ezifanelekileyo (isixhobo sokuphakamisa). Izixhobo zokubopha ezingalunganga zinokubangela umonakalo okanye ukungasebenzi ngokupheleleyo kwesixhobo sokubopha ngexesha elibi kakhulu.

Idiski yekhadibhodi ingafakwa phakathi kwesiseko se-crucible kunye nesiseko se-furnace ngaphambi kokuba ifudumale. Oku kuya kutsha, kushiye umaleko wekhabhoni phakathi kwaye kuthintele i-crucible ukuba inamathele ezantsi kwe-furnace. Ukwaleka kwePlumbago (Carbon Black) kwenza into efanayo.

Kungcono ukusebenzisa i-crucible eyahlukileyo kuhlobo ngalunye lwesinyithi ukuze uphephe ukungcola. Kwakhona qiniseka ukuba uyikhupha yonke into emva kokusetyenziswa. Isinyithi esishiywe ukuba siqine kwi-crucible sinokwanda xa sifudunyezwa kwakhona size sitshabalalise.

Nceda ufudumale ii-crucibles ezintsha okanye ezo bezigcinwe. Fudumeza i-crucible engenanto iiyure ezi-2 kwi-220 F (104 C). (Sebenzisa umoya owaneleyo. Ii-crucibles ezintsha ziya kutsha njengoko i-glaze iqina.) Emva koko tshisa i-crucible engenanto ibe bubushushu obubomvu. Vumela i-crucible iphole kubushushu begumbi esitovini ngaphambi kokuba uyisebenzise. Le nkqubo kufuneka ilandelwe kuzo ZONKE ii-crucibles ezintsha kunye nayo nayiphi na i-crucible esenokuba ichaphazeleke kwiimeko ezimanzi kwindawo yokugcina.

Gcina zonke izitya eziqhotsiweyo kwindawo eyomileyo. Ukufuma kunokubangela ukuba isitya esiqhotsiweyo siqhekeke xa sifudunyezwa. Ukuba besigcinwe ixesha elide, kungcono ukuphinda usithambise.

Ii-silicon carbide crucibles zezona zincinci kakhulu ezinokufunxa amanzi kwindawo yokugcina kwaye azidingi ukufudunyezwa ngaphambi kokusetyenziswa. Kungcono ukuba i-crucible entsha itshiswe bubushushu obubomvu ngaphambi kokuba isetyenziswe okokuqala ukuze itshiswe kwaye iqine ii-coating kunye ne-binders zasefektri.

Izinto ezisetyenzisiweyo mazibekwe kwisiqwenga esiqinileyo KAKHULU. UNGAZE “upakishe” isiqwenga esiqinileyo, njengoko izinto ezisetyenzisiweyo ziya kwanda xa zifudumala kwaye zingaqhekeza iseramikhi. Nje ukuba ezi zinto zinyibilike zibe “sisithende”, faka izinto ezingaphezulu ngononophelo edamini ukuze zinyibilike. (ISILUMKISO: Ukuba kukho naluphi na umswakama kwizinto ezintsha, kuya kubakho UKUQHUBEKA komphunga). Kwakhona, musa ukupakisha isinyithi ngokuqinileyo. Qhubeka ufaka izinto ezisetyenzisiweyo kwisiqwenga esinyibilikayo de kube kunyibilike ubungakanani obufunekayo.

ISILUMKISO!!!: IiCrucibles ziyingozi. Ukunyibilikisa isinyithi kwi-crucible kuyingozi. Ukugalela isinyithi kwiinkuni kuyingozi. I-crucibles inokusilela ngaphandle kwesilumkiso. IiCrucibles zinokuba neziphene ezifihlakeleyo kwizinto nakwimveliso ezinokukhokelela ekungaphumeleli, ekonakaleni kwepropathi, ekwenzakaleni komntu, ekwenzakaleni kwababukeleyo nasekulahlekelweni bubomi.

Ibhloko yeSiseko seCrucible

Inkcazo:

I-BCS Ibhloko yesiseko sisiseko esisetyenziswa kubushushu obuphezulu esisetyenziselwa ukuphakamisa i-crucible kwindawo yobushushu yesithando somlilo.

Oko Kukwenzayo:

Ibhloko yesiseko idla ngokusetyenziswa kwisithando somlilo esisebenza ngegesi ukuphakamisa i-crucible phezulu ukuze ilangabi le-burner lingadubuli ngqo eludongeni olubhityileyo lwe-crucible. Ukuba ilangabi le-burner livunyelwe ukuba libethe ngqo i-crucible linokubangela ukuqhekeka kodonga lwe-crucible ngaloo ndlela linciphise ubomi balo. Indlela efanelekileyo yokuthintela oku kukusebenzisa ibhloko yesiseko ukuphakamisa i-crucible iphume kwindawo ye-burner.

Ukuphakamisa i-crucible kukwavumela ukuba ibe "kwindawo yobushushu" yesithando somlilo. Nangona ilangatye lesitshisi lingena emzimbeni wesithando somlilo ezantsi, indawo eshushu kakhulu isuka embindini ukuya phezulu. Kukule ndawo apho iindonga zesithando somlilo zifudunyezwa yigesi ejikelezayo ngempumelelo. Ukuba namacala esithando somlilo kule ndawo kukhuthaza ukufudumeza okungcono kakhulu okuvela kumjelo wegesi oguquguqukayo kunye nemitha yobushushu yeendonga zangaphakathi zesithando somlilo esikhanyayo.

Indlela Yokuyisebenzisa:

Ibhloko esisiseko kufuneka ibe nde ngokwaneleyo ukuze ilangatye lesitshisi lihambelane nomphezulu webhloko. Kulungile ukuba umphezulu webhloko uphezulu kune-inlet yesitshisi. Into ongayifuniyo kukuba ilangatye libethe amacala amancinci esitshisi. Kuyamkeleka nokuba ilangatye libethe inxalenye esezantsi yesitshisi etyebileyo njengoko le nxalenye ingenakugugiswa yigesi.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.