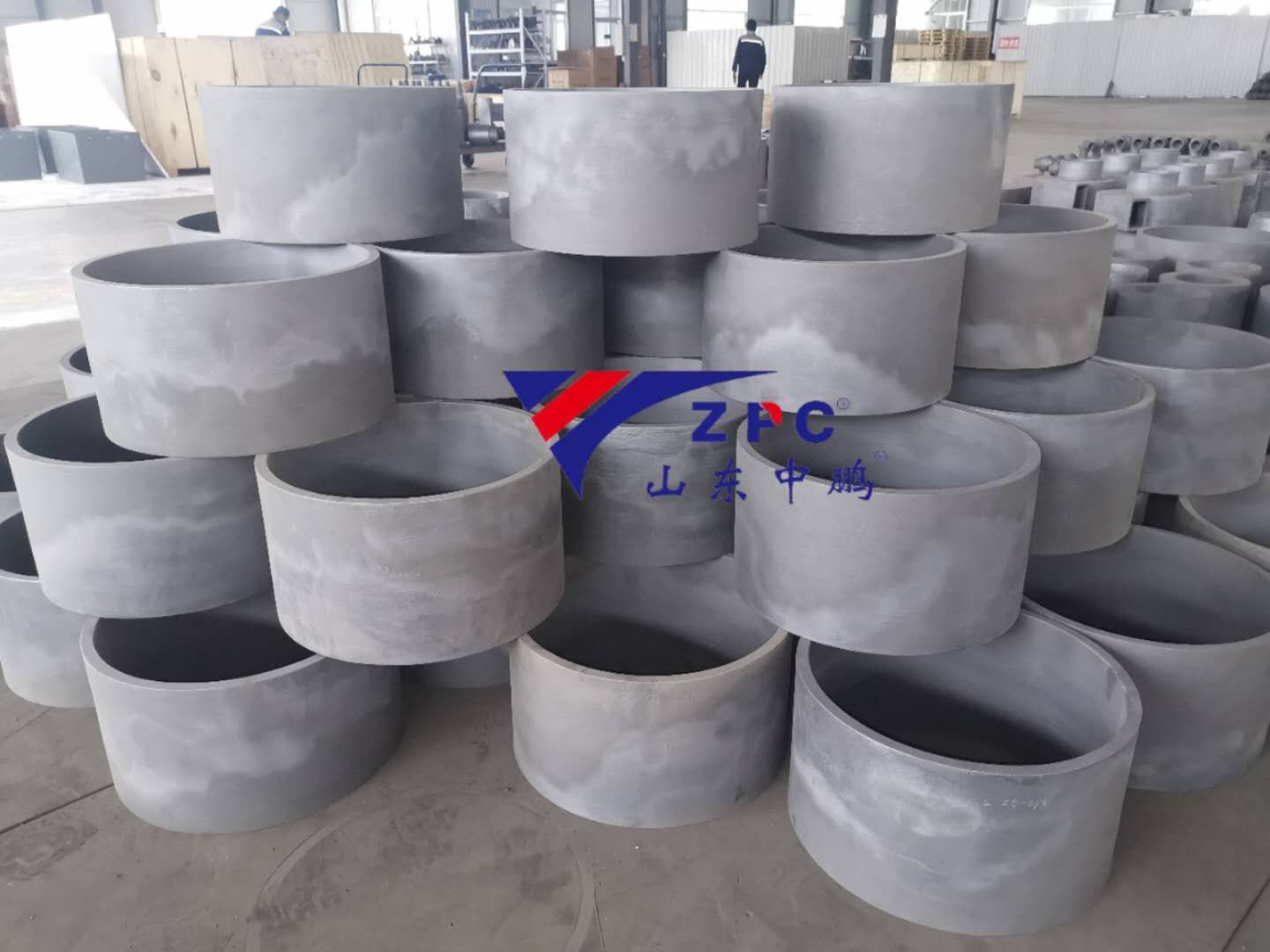

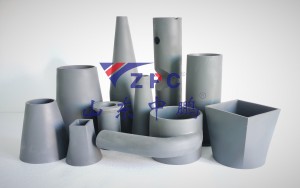

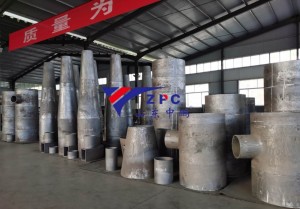

Cov khoom siv ceramic silicon carbide

Silicon carbide hnav-resistant lining

Cov Qauv Tsim ntawm Silicon Carbide (SiC) Cov Khaub Ncaws Uas Tiv Thaiv Tau:

(1) Kev Tsim Txoj Kev Nqus Dej Zoo

Ib daim duab du thiab zoo nkauj los ntawm qhov nkag mus rau qhov tawm txo qhov tsis kam ntawm cov dej ntws, ua rau SiC liners hloov kho tau rau ntau yam kev siv hauv kev lag luam.

(2) Kev Ua Kom Muaj Peev Xwm Ntau Ntxiv

MechanismCov kua dej raug atomized rau hauv cov tee dej me me los ntawm kev sib tsoo tangential nrog cov nplaim helical ntawm SiC liner nqaim zuj zus, ua kom muaj kev faib tshuaj tsuag sib xws.

(3) Qauv me me, tsis muaj kev txhaws

Ib txoj kab ntws ncaj nraim, tsis muaj lub plawv tshem tawm cov teeb meem sab hauv, ua kom cov kua dej ntws tau zoo tshaj plaws hauv cov yeeb nkab uas nqaim thiab tiv thaiv kev thaiv.

(4) Ob Hom Tshuaj Tsuag Rau Kev Ua Haujlwm Zoo Dua

Txhawb nqa ob qho tib si solid-cone thiab hollow-cone spray qauv, muab cov ces kaum dav dav thiab kev tiv thaiv kev txhaws rau kev ua haujlwm zoo.

Cov txiaj ntsig zoo dua piv rau lwm cov ntaub ntawv:

(1) Kev Tiv Thaiv Hnav Tsis Sib Xws

Qhov Nyuaj: SiC liners ua tiav Mohs hardness ntawm 9.5 (vs. 8.0 rau alumina ceramics, 6.0 rau high-chromium steel), ua rau lawv tiv taus kev hnav abrasive hnyav hauv kev tsuas slurries, thee tshauv, thiab hmoov hlau.

Lub neej ntev: Kev pab cuam lub neej tshaj 5–10 × cov ntaub ntawv ib txwm muaj (piv txwv li roj hmab lossis polyurethane liners) hauv cov ntawv thov muaj zog xws li cov tshuab sib tsoo pob lossis cov twj tso kua mis slurry.

(2) Kev xeb thiab tshuaj lom neeg tsis muaj zog

Kev Tiv Thaiv Acid/Alkali: Tiv taus cov concentrated sulfuric acid (98%), sodium hydroxide (50%), thiab cov ntsev molten (piv txwv li NaCl-KCl ntawm 800 ° C), thaum cov hlau corrode sai thiab polymers degrade.

Tsis Muaj Kev Ua Phem: Qhov chaw tsis ua haujlwm ua kom muaj kev ntshiab hauv kev tsim cov roj teeb semiconductor lossis lithium, tsis zoo li cov hlau uas yooj yim rau ion leaching.

(3) Kev Ruaj Ntseg Kub Heev

Kev Ruaj Khoov Thermal: Ua haujlwm tas li ntawm 1,600 ° C (vs. alumina qhov txwv 1,200 ° C) nrog qhov nthuav dav thermal tsawg kawg nkaus (CTE: 4.0 × 10⁻⁶ / ℃), tiv thaiv kev tawg hauv qhov cub lossis cov cub tawg.

Kev Tiv Thaiv Kev Poob Siab Thermal: Tswj kev ruaj khov ntawm cov qauv hauv qab qhov kub thiab txias sai (piv txwv li quenching ntawm 1,000 ° C mus rau chav tsev kub), tsis zoo li brittle ceramics.

(4) Kev Siv Hluav Taws Xob Zoo thiab Kev Tsim Qauv Sib Nqus

Kev Sib Txhuam Qis: Qhov chaw SiC uas tau txhuam tiav lawm (Ra <0.1 μm) txo qhov kev tiv thaiv kua los ntawm 30–50% piv rau cov hlau tsis huv, txo cov nqi zog twj.

Kev Txuag Qhov Hnyav: Qhov ceev ntawm 3.1 g / cm³ (vs. hlau 7.8 g / cm³) yooj yim rau kev teeb tsa thiab txhawb nqa cov khoom siv sib dua hauv aerospace lossis cov chaw ua haujlwm txawb.

Shandong Zhongpeng Special Ceramics Co., Ltd yog ib qho ntawm cov khoom siv tshiab silicon carbide ceramic loj tshaj plaws hauv Suav teb. SiC technical ceramic: Moh qhov nyuaj yog 9 (New Moh qhov nyuaj yog 13), nrog kev tiv thaiv zoo heev rau kev yaig thiab xeb, kev puas tsuaj zoo heev - kev tiv thaiv thiab kev tiv thaiv oxidation. SiC cov khoom lub neej kev pabcuam yog 4 txog 5 zaug ntev dua li 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 zaug ntawm SNBSC, nws tuaj yeem siv rau cov duab nyuaj dua. Cov txheej txheem hais nqe yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob rau tsis muaj leej twg. Peb ib txwm mob siab rau kev sib tw peb lub hom phiaj thiab muab peb lub siab rov qab rau lub zej zog.