Dahaarka dhoobada ee silikoon carbide

Dahaarka u adkaysta xirashada carbide ee silicon

Astaamaha Naqshadeynta Dahaarka Xirmooyinka Iska Difaacsan ee Silicon Carbide (SiC):

(1) Naqshadeynta Waddada Socodka ee La Fududeeyay

Qaab siman oo siman oo laga bilaabo albaabka ilaa albaabka ayaa yareeya iska caabbinta socodka, taasoo ka dhigaysa khadadka SiC inay la qabsan karaan codsiyada warshadaha ee kala duwan.

(2) Atomization-ka Sare

Habka Dareeraha waxaa lagu atomiyaa dhibco yaryar iyada oo loo marayo isku dhacyo tangential ah iyadoo si tartiib tartiib ah loo cidhiidhiyo dusha sare ee helical-ka ee lakabka SiC, taasoo hubinaysa qaybinta buufinta isku midka ah.

(3) Qaab-dhismeed kooban, oo aan lahayn xannibaad

Kanaal socod oo toosan oo aan xudunta lahayn ayaa baabi'iya caqabadaha gudaha, isagoo sare u qaadaya wax soo saarka dareeraha ee cabbirka tuubooyinka xaddidan iyadoo ka hortagaysa xannibaadaha.

(4) Qaababka Buufinta Labada ah si loo Xoojiyo Waxtarka

Waxay taageertaa qaababka buufinta ee koollada adag iyo kuwa godan, iyadoo bixisa xaglo ballaaran oo daboolid ah iyo waxqabad ka hortagga xannibaadda si loogu isticmaalo hawlgallo waxtar sare leh.

Faa'iidooyinka Muhiimka ah marka loo eego agabka kale:

(1) Iska caabinta Xidhmada Aan La Midayn

Adkaanta: Dahaarka SiC wuxuu gaaraa adkaanta Mohs ee 9.5 (marka la barbar dhigo 8.0 dhoobada alumina, 6.0 birta chromium-ka sare leh), taasoo u suurta gelinaysa inay u adkeystaan xiirashada xad dhaafka ah ee slurries-ka macdanta, dambaska dhuxusha, iyo budada birta.

Cimriga: Cimriga adeeggu wuxuu ka badan yahay 5-10× agab dhaqameed (tusaale ahaan dahaarka cinjirka ama polyurethane) ee codsiyada saamaynta sare leh sida mashiinnada kubbadda ama bamka slurry.

(2) Daxalka iyo Kala-soocidda Kiimikada

Iska caabbinta Aashitada/Alkaalka: Waxay iska caabisaa aashitada sulfuric ee xooggan (98%), sodium hydroxide (50%), iyo cusbada dhalaalaysa (tusaale ahaan NaCl-KCl heerkulkiisu yahay 800°C), halka biraha si dhakhso ah u mirqaansan yihiin oo polymers-ku ay burburaan.

Wasakhowga Eber: Dusha sare ee aan falcelinta lahayn waxay hubisaa daahirnimada wax soo saarka baytariyada semiconductor ama lithium, si ka duwan biraha birta ah ee u nugul daadinta ion.

(3) Xasilloonida Heerkulka Xad-dhaafka ah

Adkeysiga Kulaylka: Waxay si joogto ah ugu shaqeysaa 1,600°C (marka loo eego xadka 1,200°C ee alumina) iyadoo leh ballaarinta kulaylka ugu yar (CTE: 4.0×10⁻⁶/℃), taasoo ka hortagaysa dildilaaca foornada ama foornada dhalaalaysa.

Iska caabinta Shoogga Kulaylka: Waxay ilaalisaa hufnaanta qaab-dhismeedka marka heerkulku si degdeg ah u kordho (tusaale ahaan, daminta laga bilaabo 1,000°C ilaa heerkulka qolka), si ka duwan dhoobada jilicsan.

(4) Hufnaanta Tamarta iyo Naqshadaynta Fudud

Iska-horimaad Hoose: Dusha sare ee SiC la safeeyey (Ra <0.1 μm) waxay yareysaa iska caabbinta dareeraha 30-50% marka loo eego dahaarka birta qallafsan, taasoo yareyneysa kharashka tamarta bamgareynta.

Kaydinta Miisaanka: Cufnaanta 3.1 g/cm³ (marka la barbar dhigo 7.8 g/cm³ ee birta) waxay fududeysaa rakibidda waxayna taageertaa qalabka fudud ee ku jira cutubyada hawada sare ama kuwa gacanta lagu farsameeyo.

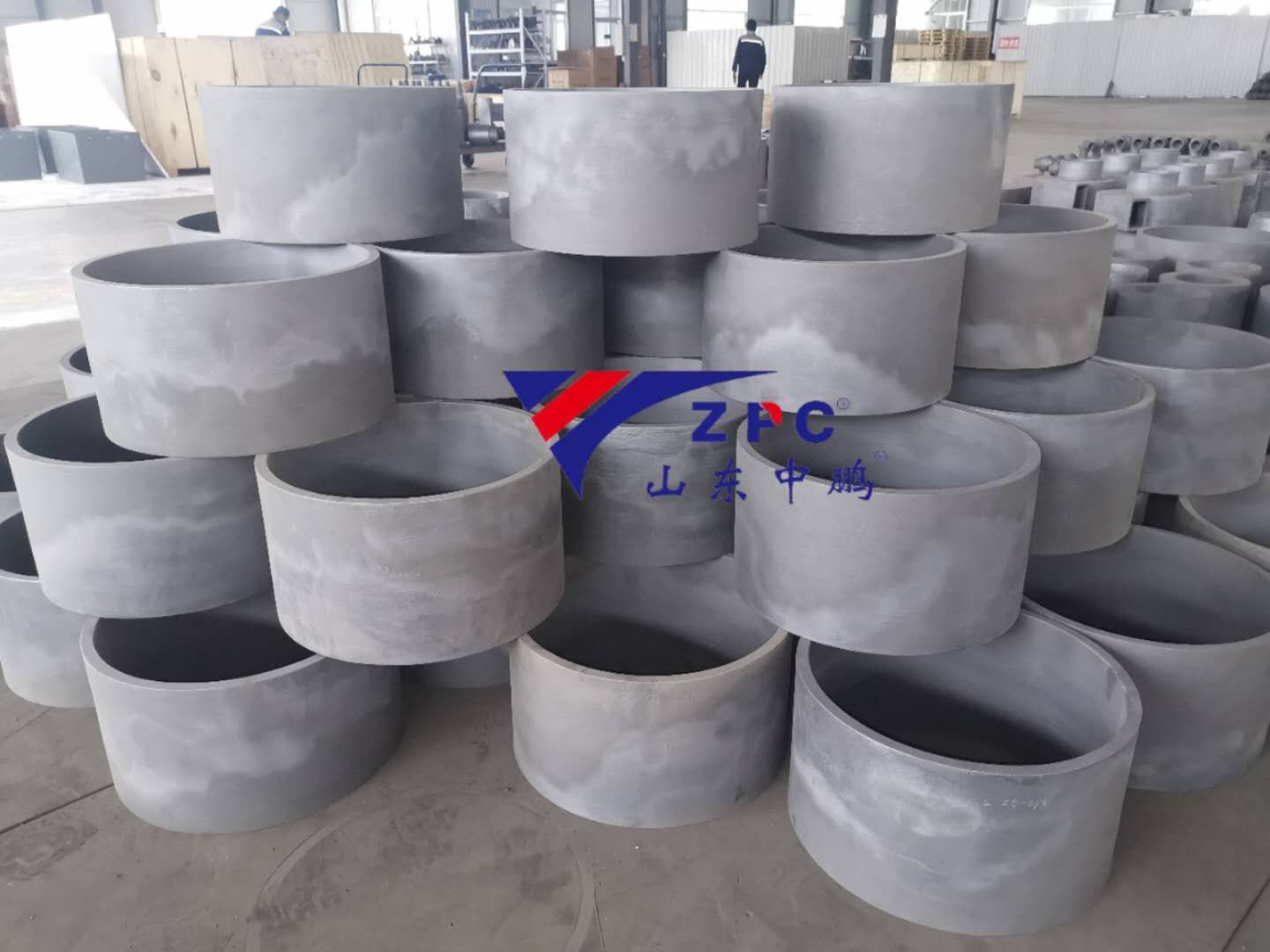

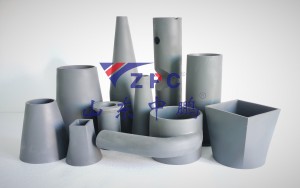

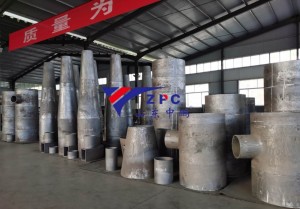

Shirkadda Shandong Zhongpeng Special Ceramics Co., Ltd waa mid ka mid ah xalalka ugu waaweyn ee walxaha cusub ee dhoobada ah ee silicon carbide ee Shiinaha. Dhoobada farsamada ee SiC: Adkaanshaha Moh waa 9 (adkeysiga New Moh waa 13), oo leh iska caabin aad u fiican oo ka dhan ah nabaad-guurka iyo daxalka, xoqid aad u fiican - iska caabin iyo ka-hortagga oksaydhka. Nolosha adeegga ee badeecada SiC waa 4 ilaa 5 jeer ka dheer 92% walxaha alumina. MOR ee RBSiC waa 5 ilaa 7 jeer ka badan SNBSC, waxaa loo isticmaali karaa qaabab badan oo adag. Habka xigashada waa mid degdeg ah, gaarsiintu waa sidii la ballanqaaday tayadana waa mid aan la barbar dhigi karin. Had iyo jeer waxaan ku adkaysannaa inaan ka hortagno yoolalkayaga oo aan qalbiyadeenna dib ugu celinno bulshada.