Li-liners tsa ceramic tsa silicon carbide

Lesela le sa keneng ka silicon carbide

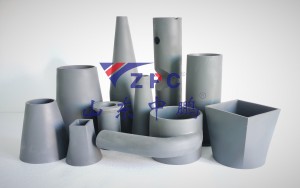

Litšobotsi tsa Moralo oa Li-Liner tse Hanelang ho Tloha tsa Silicon Carbide (SiC):

(1) Moralo oa Tsela ea Phallo e Lokisitsoeng

Sebopeho se boreleli, se otlolohileng ho tloha monyako ho ea ho o mong se fokotsa ho hanyetsa phallo, se etsa hore li-liner tsa SiC li ikamahanye le lits'ebetso tse fapaneng tsa indasteri.

(2) Ho atomization e Tsoetseng Pele

Mechine Metsi a fetoha marotholi a manyane ka ho thulana ha tangential ka ho sesefala butle-butle ha bokaholimo ba helical ba SiC liner, ho netefatsa kabo e ts'oanang ea spray.

(3) Sebopeho se Senyenyane, se se nang ho koaleha

Mokero o otlolohileng, o se nang motheo o felisa litšitiso tsa ka hare, o eketsa phallo ea mokelikeli ka har'a litekanyo tsa liphaephe tse koetsoeng ha o ntse o thibela litšitiso.

(4)Mekhoa e 'Meli ea Spray bakeng sa Bokgoni bo Ntlafalitsoeng

E tšehetsa mekhoa ea ho fafatsa ea likhoune tse tiileng le tse se nang letho, e fana ka likhutlo tse pharaletseng tsa tšireletso le ts'ebetso ea ho thibela ho koaloa ha likhoune bakeng sa ts'ebetso e sebetsang hantle haholo.

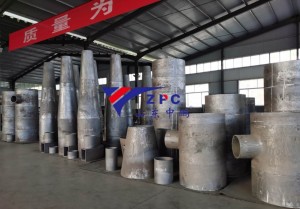

Melemo ea mantlha ha e bapisoa le thepa e 'ngoe:

(1) Khanyetso e sa Bapisoeng ea ho Roala

Bothata: Li-liner tsa SiC li fumana boima ba Mohs ba 9.5 (ha ho bapisoa le 8.0 bakeng sa liserami tsa alumina, 6.0 bakeng sa tšepe e nang le chromium e ngata), e li nolofalletsang ho mamella ho senyeha ho hoholo ha mashala a merafong, molora oa mashala le phofo ea tšepe.

Nako e Telele: Bophelo ba tšebeletso bo feta 5–10× thepa ea setso (mohlala, li-liners tsa rabara kapa tsa polyurethane) lits'ebetsong tse nang le tšusumetso e kholo joalo ka li-ball mill kapa lipompo tsa slurry.

(2) Ho se sebetse hantle ha dikhemikhale le ho se sebetse hantle ha dikhemikhale

Ho Hanela Asiti/Alkali: E hanela asiti e matla ya sulfuric (98%), sodium hydroxide (50%), le matswai a qhibilihisitsweng (mohlala, NaCl-KCl ho 800°C), athe ditshipi di bola kapele mme di-polymer di senyeha.

Ho se silafatsoe: Bokaholimo bo sa arabeleng bo netefatsa bohloeki tlhahisong ea betri ea semiconductor kapa lithium, ho fapana le li-liners tsa tšepe tse sekametseng ho leaching ea ion.

(3) Ho Tsitsisa Mocheso o Feteletseng

Ho Ikamahanya le Thermal: E sebetsa ka ho sa feleng ho 1,600°C (ha ho bapisoa le moeli oa alumina oa 1,200°C) ka katoloso e fokolang ea mocheso (CTE: 4.0×10⁻⁶/℃), e thibela ho petsoha ka har'a li-oven kapa liontong tsa ho qhibilihisa.

Ho Hanela Tšabo ea Thermal: E boloka botsitso ba sebopeho tlas'a liphetoho tse potlakileng tsa mocheso (mohlala, ho tima ho tloha ho 1,000°C ho ea mochesong oa kamore), ho fapana le li-ceramic tse pshatlehang habonolo.

(4) Bokgoni ba Matla le Moralo o Bobebe

Khohlano e Tlase: Bokaholimo ba SiC bo bentšitsoeng (Ra <0.1 μm) bo fokotsa khanyetso ea mokelikeli ka 30–50% khahlanong le li-liner tsa tšepe tse sa tsitsang, e leng se fokotsang litšenyehelo tsa matla a ho pompa.

Phokotso ea Boima: Boima ba 3.1 g/cm³ (ha ho bapisoa le 7.8 g/cm³ ea tšepe) bo nolofatsa ho kenngoa le ho tšehetsa lisebelisoa tse bobebe liyuniting tsa ho sebetsa lifofaneng kapa tse tsamaeang.

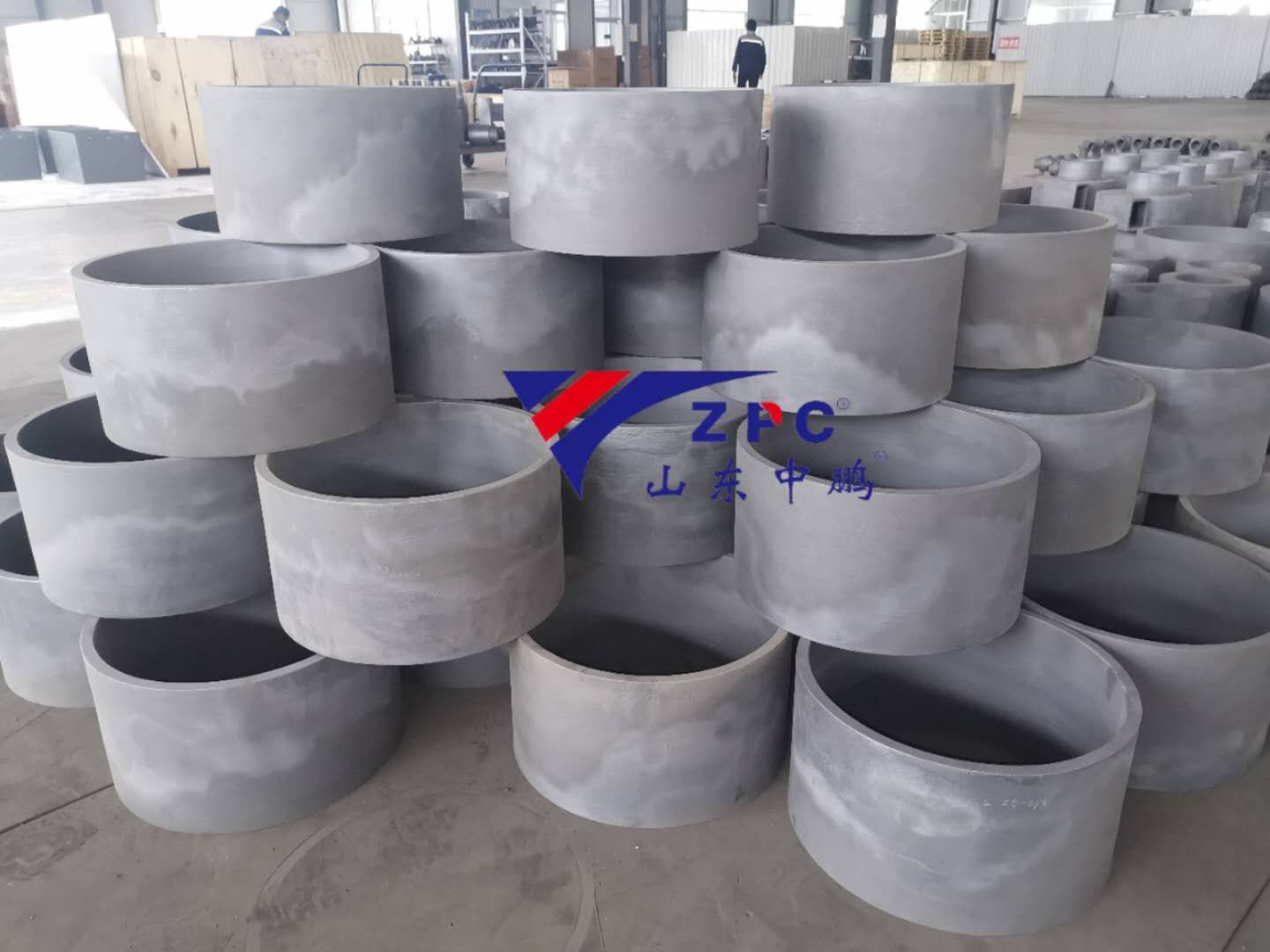

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse kholo ka ho fetisisa tsa thepa e ncha ea silicon carbide Chaena. SiC technical ceramic: Bothata ba Moh ke 9 (Bothata ba Moh bo bocha ke 13), bo nang le khanyetso e ntle khahlanong le khoholeho le mafome, khanyetso e ntle - khanyetso le anti-oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ka makhetlo a 4 ho isa ho a 5 ho feta thepa ea alumina ea 92%. MOR ea RBSiC e feta ka makhetlo a 5 ho isa ho a 7 ho feta SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea khotheishene e potlakile, phano e etsoa joalo ka ha e tšepisitsoe 'me boleng ha bo fete letho. Kamehla re phehella ho phephetsa lipheo tsa rona 'me re khutlisetsa lipelo tsa rona sechabeng.