I-Silicon Carbide FGD Nozzle yokususa i-sulfurization kwisityalo samandla

IiNozzles zokufunxa igesi ephuma kwiFlue Gas Desulfurization (FGD)

Ukususwa kwee-sulfur oxides, ezibizwa ngokuba yi-SOx, kwiigesi zokukhupha umoya kusetyenziswa i-alkali reagent, njenge-limestone slurry emanzi.

Xa amafutha efosili esetyenziswa kwiinkqubo zokutsha ukuqhuba iibhoyila, ii-oven, okanye ezinye izixhobo, anokukwazi ukukhupha i-SO2 okanye i-SO3 njengenxalenye yegesi ephumayo. Ezi sulfur oxides zisabela ngokulula nezinye izinto ukuze zenze i-compound enobungozi efana ne-sulfuric acid kwaye zinokuba nefuthe elibi kwimpilo yabantu nakwindalo esingqongileyo. Ngenxa yezi ziphumo zinokwenzeka, ulawulo lwale compound kwiigesi ze-flue luyinxalenye ebalulekileyo yezityalo zamandla ezisebenzisa amalahle kunye nezinye izicelo zoshishino.

Ngenxa yokukhukuliseka, ukuvalwa, kunye nokwakheka, enye yezona nkqubo zithembekileyo zokulawula le nkunkuma yinkqubo ye-open-tower wet flue gas desulfurization (FGD) esebenzisa ilitye lekalika, ilime emanzi, amanzi olwandle, okanye esinye isisombululo se-alkaline. Ii-spray nozzles ziyakwazi ukusasaza ezi slurry ngokufanelekileyo nangokuthembekileyo kwiinqaba zokufunxa. Ngokwenza iipateni ezifanayo zamaconsi anobukhulu obufanelekileyo, ezi nozzles ziyakwazi ukudala ngokufanelekileyo indawo yomphezulu efunekayo ukuze kufunxwe ngokufanelekileyo ngelixa zinciphisa ukufakwa kwesisombululo sokukhuhla kwigesi ye-flue.

Ukukhetha i-FGD Absorber Nozzle:

Izinto ezibalulekileyo ekufuneka ziqwalaselwe:

Uxinano lwemidiya yokuhluza kunye ne-viscosity

Ubungakanani bethontsi elifunekayo

Ubungakanani obuchanekileyo bethontsi bubalulekile ukuqinisekisa amazinga afanelekileyo okufunxa

Izinto zomlomo

Njengoko igesi yolwelo idla ngokuba yirhabaxa kwaye ulwelo lokuhlikihla luhlala luyirhabaxa enomxholo ophezulu wezinto eziqinileyo kunye neempawu zokurhawuzelela, ukukhetha izinto ezifanelekileyo zokurhawuzelela nokuguguleka kubalulekile.

Ukumelana nokuvaleka kwempumlo

Njengoko ulwelo lokuhlafuna ludla ngokuba ludaka olunezithako eziphezulu zezinto eziqinileyo, ukukhetha umlomo womlomo ngokubhekiselele ekungaxinaniseni amanzi kubalulekile.

Ipateni yesitshizi se-nozzle kunye nokubekwa kwayo

Ukuze kuqinisekiswe ukufunxwa ngokufanelekileyo, ukugubungela ngokupheleleyo umjelo wegesi ngaphandle kokudlula kunye nexesha elaneleyo lokuhlala kubalulekile

Ubungakanani boqhagamshelo lwe-nozzle kunye nohlobo

Amanqanaba okuhamba kolwelo okufunekayo ekucoceni

Ukwehla koxinzelelo olufumanekayo (∆P) kwimpumlo

∆P = uxinzelelo lombane kwindawo yokungena kwe-nozzle – uxinzelelo lwenkqubo ngaphandle kwe-nozzle

Iinjineli zethu ezinamava zinokukunceda umisele ukuba yeyiphi i-nozzle eza kusebenza njengoko kufuneka ngeenkcukacha zakho zoyilo

Ukusetyenziswa kweNozzle yeFGD Absorber kunye neMizi-mveliso:

Izityalo zamandla ezisebenzisa amalahle nezinye izinto ezisebenzisa amafutha efosili

Iindawo zokucoca ipetroliyam

Izixhobo zokutshisa inkunkuma zikamasipala

Ii-oven zesamente

Abanyibilikisi besinyithi

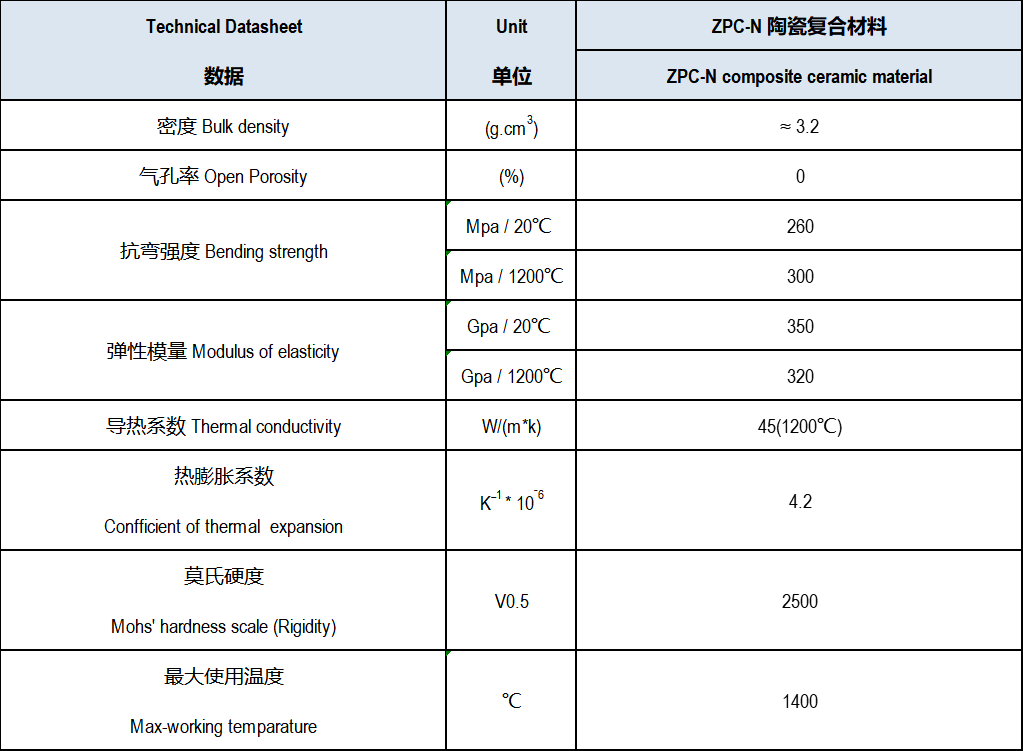

Iphepha ledatha leSiC Material

Iingxaki ngeLime/Limestone

Njengoko kubonisiwe kuMfanekiso 1, iinkqubo ze-FGD ezisebenzisa i-lime/limestone forced oxidation (LSFO) ziquka iinkqubo ezintathu eziphambili:

- Ukulungiswa, ukuphathwa kunye nokugcinwa kwee-reagent

- Isitya sokufunxa

- Ukuphathwa kwenkunkuma kunye nemveliso engasemva kwayo

Ukulungiswa kwe-reagent kuqulathe ukuhambisa i-limestone ecoliweyo (i-CaCO3) ukusuka kwindawo yokugcina ukuya kwitanki yokutya ephazamisekileyo. I-limestone slurry ephumayo emva koko ipompelwa kwisitya sokufunxa kunye negesi ye-boiler flue kunye nomoya oxovulayo. Ii-spray nozzles zihambisa amathontsi amancinci e-reagent aze ahambe ngokuchaseneyo negesi ye-flue engenayo. I-SO2 kwigesi ye-flue isabela kunye ne-calcium-rich reagent ukuze yenze i-calcium sulfite (i-CaSO3) kunye ne-CO2. Umoya ongeniswa kwi-absorber ukhuthaza i-oxidation ye-CaSO3 kwi-CaSO4 (uhlobo lwe-dihydrate).

Iimpendulo ezisisiseko ze-LSFO zezi:

CaCO3 + SO2 → CaSO3 + CO2 · 2H2O

I-oxidized slurry iqokelelana ezantsi kwe-absorber ize emva koko iphinda isetyenziswe kunye ne-reagent entsha ibuyele kwi-spray nozzle headers. Inxalenye yomjelo wokuphinda isetyenziswe irhoxiswa kwinkqubo yokuphatha inkunkuma/imveliso, edla ngokuba nee-hydrocyclones, izihluzi zedrum okanye zebhanti, kunye netanki yokubamba amanzi amdaka/utywala evuthuziweyo. Amanzi amdaka avela kwitanki yokubamba aphinda asetyenziswe kwakhona kwitanki yokutya ye-limestone reagent okanye kwi-hydrocyclone apho ukugcwala kususwa khona njengenkunkuma.

| Inkqubo yokuCoca eQhelekileyo yeLime/Limestone eQinisekisiweyo yeOxidatin emanzi |

|

Iinkqubo ze-LSFO ezimanzi zihlala zikwazi ukufikelela ekusebenzeni kakuhle kokususa i-SO2 ye-95-97 ekhulwini. Nangona kunjalo, ukufikelela kumanqanaba angaphezu kwe-97.5 ekhulwini ukuhlangabezana neemfuno zokulawula ukukhutshwa komoya, kunzima, ingakumbi kwizityalo ezisebenzisa amalahle ane-sulfur ephezulu. Ii-catalysts ze-magnesium zingongezwa okanye i-limestone ingafakwa kwi-calcined kwi-reactivity ephezulu (CaO2), kodwa olo tshintsho lubandakanya izixhobo zezityalo ezongezelelweyo kunye neendleko zomsebenzi kunye namandla ahambelanayo. Umzekelo, ukufaka i-calcine kwi-lime kufuna ukufakwa kwe-oven eyahlukileyo ye-lime. Kwakhona, i-lime ikhawuleza ivuthe kwaye oku kwandisa amathuba okwakheka kwe-scale deposit kwi-scrubber.

Ixabiso lokugaya i-calcination nge-lime oven lingancitshiswa ngokufaka i-limestone ngqo kwi-boiler oven. Kule ndlela, i-lime eveliswa kwi-boiler ithwalwa ne-flue gas kwi-scrubber. Iingxaki ezinokubakho ziquka ukungcoliswa kwe-boiler, ukuphazamiseka kokudluliselwa kobushushu, kunye nokungasebenzi kwe-lime ngenxa yokutsha kakhulu kwi-boiler. Ngaphezu koko, i-lime inciphisa ubushushu bokuhamba kothuthu olunyibilikisiweyo kwii-boilers ezisebenza ngamalahle, nto leyo ebangela ukuba kubekho ii-stali eziqinileyo ebezingenakwenzeka.

Inkunkuma engamanzi evela kwinkqubo ye-LSFO idla ngokujoliswa emachibini okuzinzisa kunye nenkunkuma engamanzi evela kwenye indawo kwisikhululo samandla. Ulwelo olumanzi lwe-FGD lunokuzaliswa yi-sulfite kunye nee-sulfate compounds kwaye izinto ezichaphazela imeko-bume zihlala zithintela ukukhululwa kwayo kwimilambo, kwimilambo okanye kwezinye iindlela zamanzi. Kwakhona, ukuphinda usebenzise amanzi amdaka/utywala ukuya kwi-scrubber kunokukhokelela ekwandeni kweetyuwa ze-sodium, potassium, calcium, magnesium okanye chloride ezinyibilikisiweyo. Ezi ntlobo ekugqibeleni zinokuqina ngaphandle kokuba kubonelelwe ukopha okwaneleyo ukugcina uxinano lwetyuwa enyibilikisiweyo lungaphantsi koxinzelelo. Ingxaki eyongezelelweyo kukukhawuleza kokuhlala kwezinto eziqinileyo zenkunkuma, okubangela imfuneko yamachibi amakhulu, anomthamo ophezulu wokuzinzisa. Kwiimeko eziqhelekileyo, umaleko ozinzileyo kwidama lokuzinzisa unokuba ne-50% okanye ngaphezulu kwesigaba solwelo nangona emva kweenyanga ezininzi zokugcina.

I-calcium sulfate efunyenwe kwi-absorber recycle slurry inokuba ne-limestone eninzi engaphendulwanga kunye nothuthu lwe-calcium sulfite. Ezi zinto zingcolisayo zinokuthintela i-calcium sulfate ukuba ithengiswe njenge-synthetic gypsum yokusetyenziswa kwi-wallboard, i-plaster, kunye ne-samente. I-limestone engaphendulwanga yeyona nto ingcolileyo ifumaneka kwi-synthetic gypsum kwaye ikwayinto engcolileyo eqhelekileyo kwi-gypsum yendalo (eyembiwayo). Nangona i-limestone ngokwayo ingaphazamisi iimpawu zeemveliso ze-wallboard end, iimpawu zayo zokurhawuzelela zibangela iingxaki zokuguguleka kwezixhobo zokucubungula. I-calcium sulfite yinto engcolileyo engafunekiyo kuyo nayiphi na i-gypsum njengoko ubungakanani bayo obuncinci bubangela iingxaki zokukhula kunye nezinye iingxaki zokucubungula ezifana nokuhlanjwa kwekhekhe kunye nokususwa kwamanzi.

Ukuba izinto eziqinileyo eziveliswa kwinkqubo ye-LSFO azithengiswa njenge-gypsum yokwenziwa, oku kubangela ingxaki enkulu yokulahla inkunkuma. Kwibhoyila eyi-1000 MW ephehla amalahle esulfure angama-1 ekhulwini, ubungakanani be-gypsum bumalunga neetoni ezingama-550 (ubufutshane) ngosuku. Kwisityalo esifanayo esiphehla amalahle esulfure angama-2 ekhulwini, imveliso ye-gypsum iyanda ukuya kuthi ga kwiitoni ezili-1100 ngosuku. Ukongeza iitoni ezili-1000 ngosuku kwimveliso yothuthu oluphaphazelayo, oku kunika itoni iyonke yenkunkuma eqinileyo ukuya kuthi ga kwiitoni ezili-1550 ngosuku kwikheyiji yamalahle esulfure engama-1 ekhulwini kunye neetoni ezingama-2100 ngosuku kwikheyiji yesulfure engama-2 ekhulwini.

Iingenelo ze-EADS

Indlela yobuchwepheshe eqinisekisiweyo endaweni yokucoca i-LSFO ithatha indawo yelimestone nge-ammonia njenge-reagent yokususa i-SO2. Izixhobo ze-reagent eziqinileyo zokusila, zokugcina, zokuphatha nezokuthutha kwinkqubo ye-LSFO zithathelwa indawo ziitanki zokugcina ezilula ze-ammonia enamanzi okanye engenamanzi. Umfanekiso 2 ubonisa isicwangciso sokuhamba kweenkqubo ze-EADS esibonelelwa yi-JET Inc.

I-Ammonia, igesi yolwelo, umoya oxoxisayo kunye namanzi asetyenziswayo angena kwi-absorber enee-nozzles ezininzi zokutshiza. Ii-nozzles zivelisa amathontsi amancinci e-reagent equlethe i-ammonia ukuqinisekisa unxibelelwano olusondeleyo lwe-reagent negesi yolwelo engenayo ngokweempendulo ezilandelayo:

(1) SO2 + 2NH3 + H2O → (NH4)2SO3

(2) (NH4)2SO3 + ½O2 → (NH4)2SO4

I-SO2 kumjelo wegesi ye-flue idibana ne-ammonia kwisiqingatha esiphezulu sesitya ukuze ivelise i-ammonium sulfite. Umzantsi wesitya se-absorber usebenza njengetanki ye-oxidation apho umoya u-oxidation kwi-ammonium sulfite kwi-ammonium sulfate. Isisombululo se-ammonium sulfate esiphumayo sipontshwa sibuyele kwi-spray nozzle headers kumanqanaba ahlukeneyo kwi-absorber. Ngaphambi kokuba igesi ye-flue ekhutshiweyo iphume phezulu kwe-absorber, idlula kwi-demister edibanisa naziphi na ii-drops zolwelo ezifakwe ngaphakathi kwaye ibambe ii-particles ezincinci.

I-ammonia reaction ene-SO2 kunye ne-sulfite oxidation kwi-sulfate ifikelela kwisantya esiphezulu sokusetyenziswa kwe-reagent. Iikhilogram ezine ze-ammonium sulfate ziveliswa kwikhilogram nganye ye-ammonia esetyenzisiweyo.

Njengakwinkqubo ye-LSFO, inxalenye yomsinga wokuphinda usebenzise i-reagent/imveliso ingarhoxiswa ukuze kuveliswe imveliso engaphantsi kwezorhwebo. Kwinkqubo ye-EADS, isisombululo semveliso yokuthatha sipontshwa kwinkqubo yokubuyisela izinto eziqinileyo equlathe i-hydrocyclone kunye ne-centrifuge ukuze kugxilwe kwimveliso ye-ammonium sulfate ngaphambi kokuba yomiswe kwaye ipakishwe. Zonke izinto ezimanzi (i-hydrocyclone overflow kunye ne-centrifuge centrate) zibuyiselwa kwi-slurry tank kwaye emva koko ziphinde zingeniswe kumsinga wokuphinda usebenzise i-ammonium sulfate.

- Iinkqubo ze-EADS zibonelela ngokusebenza kakuhle kokususa i-SO2 (>99%), nto leyo enika izityalo zamandla ezisebenzisa amalahle ukuguquguquka ngakumbi kokuxuba amalahle esulfure angabizi kakhulu nanexabiso eliphezulu.

- Nangona iinkqubo ze-LSFO zenza iitoni eziyi-0.7 ze-CO2 kwitoni nganye ye-SO2 esusiweyo, inkqubo ye-EADS ayivelisi CO2.

- Ngenxa yokuba ilayimu kunye nelitye lekalika azinampembelelo ingako xa kuthelekiswa ne-ammonia yokususa i-SO2, ukusetyenziswa kwamanzi amaninzi kunye namandla okupompa kuyafuneka ukuze kufezekiswe amazinga aphezulu okujikeleza kwegazi. Oku kuphumela kwiindleko eziphezulu zokusebenza kweenkqubo ze-LSFO.

- Iindleko ezinkulu zeenkqubo ze-EADS ziyafana nezo zokwakha inkqubo ye-LSFO. Njengoko kuphawuliwe apha ngasentla, nangona inkqubo ye-EADS ifuna izixhobo zokucubungula kunye nokupakisha i-ammonium sulfate, izixhobo zokulungiselela i-reagent ezinxulumene ne-LSFO azifuneki xa kusikwa, kuphathwa kwaye kuthuthwa.

Eyona nzuzo ibalaseleyo ye-EADS kukususa inkunkuma engamanzi kunye nenkunkuma eqinileyo. Itekhnoloji ye-EADS yinkqubo yokukhupha ulwelo olungenanto, nto leyo ethetha ukuba akukho mfuneko yonyango lwamanzi amdaka. Imveliso engaphantsi kwe-ammonium sulfate eqinileyo ithengiswa ngokulula; i-ammonium sulfate yeyona nxalenye yesichumisi kunye nesichumisi esetyenziswa kakhulu kwihlabathi liphela, kwaye kulindeleke ukukhula kwemarike kwihlabathi liphela ukuya kuthi ga ngo-2030. Ukongeza, ngelixa ukwenziwa kwe-ammonium sulfate kufuna i-centrifuge, i-dryer, i-conveyor kunye nezixhobo zokupakisha, ezi zinto azinazo iipropati kwaye ziyafumaneka kurhwebo. Ngokuxhomekeke kwiimeko zoqoqosho nezemarike, isichumisi se-ammonium sulfate sinokunciphisa iindleko zokususa i-flue gas esekwe kwi-ammonia kwaye sinokubonelela ngenzuzo enkulu.

| Inkqubo yokucoca i-Ammonia esebenzayo |

|

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.