Iimpumlo ze-FGD Absorber slurry spray

UKUTSHINTSHWA KWEGESI YEFLUE EMNYAMA NGOKUNXITYISWA KWELIME/ILIMESTERONE

Iimbonakalo

Ukusebenza kakuhle kwe-desulphurization engaphezulu kwe-99% kunokufezekiswa

Ukufumaneka okungaphezulu kwe-98% kunokufezekiswa

Ubunjineli abuxhomekekanga kwindawo ethile

Imveliso ethengiswayo

Umsebenzi womthwalo wenxalenye ongenamkhawulo

Indlela enenani elikhulu leereferensi kwihlabathi liphela

Ukucocwa kwegesi yolwelo ngokumiswa kwelayimu

Ukuze igesi ye-flue inyibilike i-sulphurization emanzi, idlula kwi-absorber (scrubber). I-lime suspension efumaneka kwi-absorber (i-limestone okanye ubisi lwe-lime) idibana ne-sulphur dioxide evela kwigesi ye-flue. Okukhona ukuhanjiswa kobunzima kulunge ngakumbi, kokukhona i-desulphurization isebenza ngcono.

Ngaxeshanye nokufunxwa kwayo, igesi yolwelo igcwala umphunga wamanzi. Oko kubizwa ngokuba “yigesi ecocekileyo” kudla ngokukhutshwa ngetshimini emanzi okanye ngenqaba yokupholisa. Amanzi alahlekileyo ngaloo ndlela kufuneka atshintshwe. I-lime slurry epompelwa kwi-circulation igcinwa isebenza ngokweekhemikhali ngokufunxa amanzi amaninzi agcweleyo aze ayitshintshe nge-reactive suspension entsha. Ukuhamba kwenxalenye ekhutshiweyo kuqulethe i-gypsum, - elula - yimveliso ye-reaction yelayimu kunye ne-sulphur kwaye inokuthengiswa emva kokukhutshelwa amanzi (umz. kwiindonga ze-gypsum kushishino lokwakha).

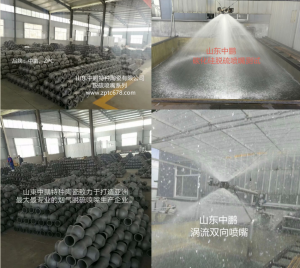

Ii-nozzles ezikhethekileyo ze-ceramic zisetyenziselwa ukufaka i-lime suspension kwi-absorber. Ezi nozzles zenza amaconsi amaninzi amancinci avela kwi-suspension epompelweyo kwaye ngaloo ndlela zibe ngumphezulu omkhulu wempendulo ukuze kudluliselwe ubunzima obuhle. Izinto ze-ceramic zivumela ubomi obude benkonzo nangona i-lime suspension enomxholo we-gypsum ineempawu zokurhawuzelela. Kuyilo sibeka ukubaluleka okukhulu kwiindawo ezinqamlezileyo zasimahla, ukuze ukungcola okuncinci kwi-suspension kungabi nakho ukuseta ii-nozzles. Ukuze kusetyenziswe ngendlela engabizi kakhulu, ezi nozzles zinokulungiswa kuluhlu oluphezulu lokusebenza kwepompo. I-nozzle ingachazwa (phantse) kuyo yonke imingeni yobunjineli benkqubo. Ukongeza kwi-nozzles ze-full-cone kunye ne-hollow-cone kwii-engile ezahlukeneyo zokutshiza kunye namazinga okuhamba, i-nozzle ye-ZPC ene-patented twist compensation nayo iyafumaneka.

Indawo yokufunxa inamanqanaba aliqela eempumlo kunye nenkqubo yokwahlula amathontsi efakwe ngokuthe tye, ukuze kubuyiselwe amathontsi amancinci athwalwa kumjelo wegesi kwinkqubo. Ngee-droplet separators zethu ezisebenza kakuhle ungandisa ukusebenza kakuhle kwesityalo sakho.

Izinto eziqinileyo ezikwi-suspension zingakhokelela kwiidiphozithi, umz. kwi-droplet separator, kwi-inlet duct okanye kwimibhobho, nto leyo enokubangela iingxaki ekusebenzeni. Ekubeni amanzi ehlala ekhutshwa kwisekethe ngokuphuma komphunga, amanzi kufuneka afakwe kwi-absorber, enokusetyenziswa kwaye ifanele isetyenziswe ekucoceni. Ii-ZPC tongue nozzles ziye zazibonakalisa ukuba ziyacoca i-flue gas inlet. Ii-ZPC full cone nozzles zihlala zisetyenziselwa ukucoca ii-droplet separators.

Iiplastiki (umz. zemibhobho) kunye nerabha (umz. iigasket, iilining zerabha, njl.njl.) zihlala zisetyenziswa kwi-absorber enokumelana nobushushu obuphantsi kunobushushu begesi yeflue engapholiyo. Ngokwesiqhelo, i-suspension epompelwa kwisekethe ipholisa igesi yeflue ngokwaneleyo, kodwa ukuba, umzekelo, ipompo yokutya ixhonyiwe, iiplastiki kunye neerabha zinokutshatyalaliswa. Ii-nozzles ezincinci zesinyithi ezikhethekileyo ziye zabonakalisa ixabiso lazo apha, ezithatha indawo yokupholisa ngeli xesha kwaye ngaloo ndlela zikhusela utyalo-mali lwesityalo se-flue gas desulphurisation.

I-Reaction bonded silicon carbide (SiSiC): Ubunzima bukaMoh buyi-9.2, bunokumelana okuhle nokukhukuliseka kunye nokugqwala, bumelana kakuhle nokukrweleka kunye nokulwa ne-oxidation. Bunamandla ngokuphindwe ka-4 ukuya ku-5 kune-nitride bonded silicon carbide. Ubomi benkonzo bude ngokuphindwe ka-7 ukuya ku-10 kune-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezintsonkothileyo ngakumbi.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.