Silicon Carbide Full Cone Sprial nozzle

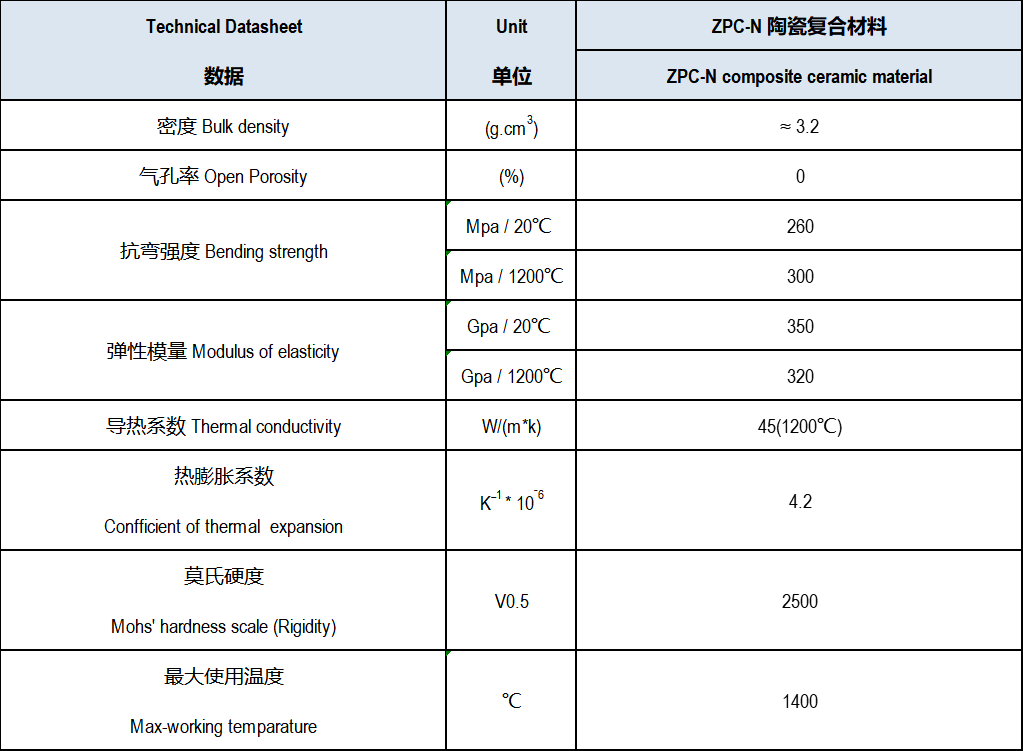

Leqephe la Boitsebiso la Tekheniki:

Molao-motheo oa ho sebetsa oa nozzle ea spiral ea silicon carbide

Ha mokelikeli o nang le kgatello le lebelo le itseng o phalla ho tloha holimo ho ya tlase ho RBSC/SiSiC spiral nozzle, mokelikeli karolong e ka ntle o otla helicoid ka sekhutlo se itseng ho nozzle. Sena se ka fetola tsela ya spray hole le nozzle. Sekhutlo se kenyelleditsweng (sekhutlo sa helix) pakeng tsa ho phalla ha bokaholimo ba khoune ya dikarolo tse fapaneng le bohareng ba nozzle se fokotseha butle-butle.Ho eketsa sebaka se koahelang mokelikeli o ntšitsoeng ka katleho hoa thusa.

Nozzle ea RBSC/SiSiC spiral ke sesebelisoa se sebelisoang haholo ho tlosa sulphurization le ho tlosa lerōle. E ka hlahisa khoune e se nang letho le sebopeho sa spray ea khoune e tiileng ka sekhutlo sa spiral ho tloha likhatong tse 60 ho isa ho tse 170. Ka ho seha le ho thulana le 'mele o monyane o tsoelang pele oa spiral, mokelikeli o tla fetoha mokelikeli o monyane ka har'a sekoti sa nozzle. Moralo oa tsela ho tloha ho kenngoeng ho ea kantle ha o sitisoe ke lehare le tataiso efe kapa efe. Tabeng ea phallo e tšoanang, bophara bo boholo bo sa thibeloang ba nozzle ea spiral bo feta makhetlo a 2 ho feta nozzle ea setso. Sena se ka fokotsa ho hlaha ha tšitiso ka tekanyo e kholo.

Silicon Carbide ke thepa e bobebe, e thata haholo, le e hanelang mafome e leng se etsang hore e be khetho e matla bakeng sa ts'ebeliso ea ho tsofala libakeng tse thata ka ho fetisisa. Silicon Carbide e boetse e fana ka thepa e meng e lakatsehang joalo ka ho tsamaisa mocheso hantle le modulus e nyane e phahameng.

- Likopo

- Lisebelisoa tsa ts'ebetso ea semiconductor Likarolo

- Likarolo tsa mechine ea indasteri e akaretsang

- Karolo ea ho hanyetsa abrasion

Nozzle ea ho tlosa sulphurization ea vacuum reaction e nang le sintered silicon carbide ke karolo ea bohlokoa ea sete e felletseng ea lisebelisoa tsa ho tlosa sulphurization le lerōle bakeng sa feme ea motlakase ea mocheso, boiler e kholo. Sehlahisoa se na le thepa e ntle haholo joalo ka matla a phahameng, ho thatafala ho hoholo, ho hanyetsa ho hoholo ha mafome, ho tsofala ho matla le ho hanyetsa mocheso o phahameng. Atomizer ea ho tlosa sulphurization ea silicon carbide e nang le karabelo e hlahisoang ke k'hamphani ea rona e na le kabo e ts'oanang ea marotholi a spray, likanale tsa phallo tse sa sitisoeng, le lihlahisoa tse tsoang kantle ho naha tse nkeloang sebaka ka botlalo, li tlatsa sekheo sa lapeng. Hona joale, ho na le letoto le le leng la li-vortices, li-spiral le likholomo tsa metsi, tse sebelisitsoeng lisebelisoa tsa ho tlosa sulphurization le ho tlosa lerōle tsa limela tse ngata tsa motlakase oa mocheso le li-boiler tse kholo, 'me li boemong bo botle ba ho sebetsa.

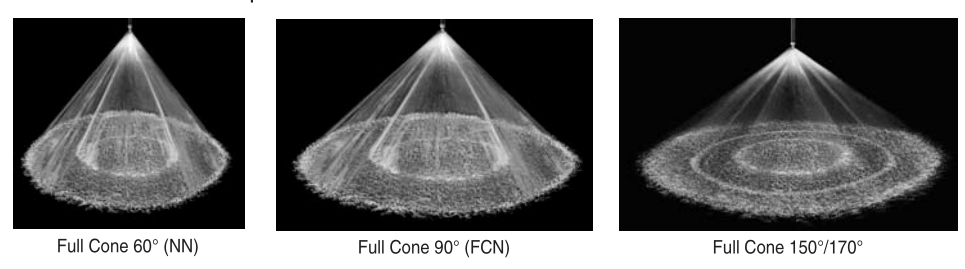

Phello ea spray ea li-nozzle tsa spiral tsa khoune e tiileng

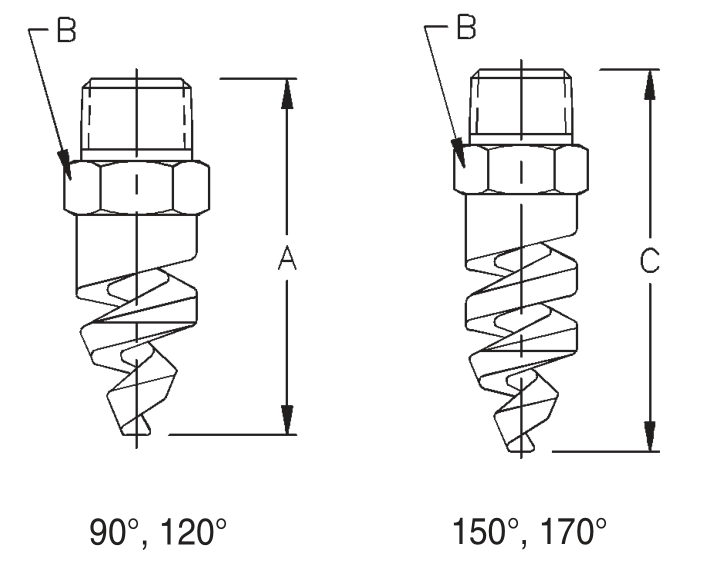

Litefiso le Litekanyo tsa Phallo ea Khoune e Felletseng

Khoune e Felletseng, 60° (NN), 90° (FCN kapa FFCN), 120° (FC kapa FFC), 150°, le 170° Spray Angles, 1/8″ ho isa ho 4″ Boholo ba Liphaephe

Likhutlo tsa Spray:

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse kholo ka ho fetisisa tsa thepa e ncha ea silicon carbide Chaena. SiC technical ceramic: Bothata ba Moh ke 9 (Bothata ba Moh bo bocha ke 13), bo nang le khanyetso e ntle khahlanong le khoholeho le mafome, khanyetso e ntle - khanyetso le anti-oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ka makhetlo a 4 ho isa ho a 5 ho feta thepa ea alumina ea 92%. MOR ea RBSiC e feta ka makhetlo a 5 ho isa ho a 7 ho feta SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea khotheishene e potlakile, phano e etsoa joalo ka ha e tšepisitsoe 'me boleng ha bo fete letho. Kamehla re phehella ho phephetsa lipheo tsa rona 'me re khutlisetsa lipelo tsa rona sechabeng.