When the tailings slurry of the mine impacts the pipeline at high speed, when the high-temperature slag in the metallurgical workshop continues to wash the inner wall, and when the strong acid solution in the chemical workshop corrodes the pipe wall day after day – ordinary metal pipelines often leak after only a few months. But there is a type of pipeline that can survive in such an “industrial purgatory” unscathed, and it is a wear-resistant pipeline made of silicon carbide as the core material. What kind of material intelligence does this seemingly ordinary industrial component hide?

A more stubborn material code than steel

The story of silicon carbide began in the late 19th century when scientists accidentally discovered this hard compound while attempting to manufacture synthetic diamond. It is extremely rare in nature and is known as “Moissanite”, while the silicon carbide used in industry today is almost entirely a product of artificial synthesis.

The secret to making silicon carbide pipes so “resistant to manufacturing” lies in their unique microstructure. Under an electron microscope, silicon carbide crystals exhibit a tetrahedral structure similar to diamond, with each silicon atom tightly surrounded by four carbon atoms, forming an unbreakable covalent bond network. This structure gives it a hardness second only to diamond, with a Mohs hardness of 9.5, which means that even continuous erosion of quartz sand (Mohs hardness of 7) is difficult to leave traces.

What’s even more rare is that silicon carbide is not only hard, but also highly resistant to high temperatures. At a high temperature of 1400 ℃, it can still maintain stable mechanical properties, which makes it perform well in high-temperature scenarios such as coal powder transportation in steel metallurgy blast furnaces and boiler slag discharge in thermal power generation. At the same time, it is “immune” to the erosion of most acids and alkalis, and this corrosion resistance is particularly precious in strong acid transmission pipelines in the chemical industry.

Design philosophy to increase pipeline lifespan tenfold

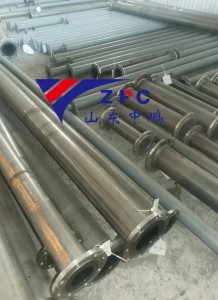

Simple hardness is not enough to cope with complex industrial environments. Modern silicon carbide wear-resistant pipelines adopt smarter composite structures: usually the outer layer is ordinary carbon steel that provides structural support, the inner layer is silicon carbide ceramic lining, and some pipelines also wrap fiberglass on the outside to enhance overall strength. This design not only leverages the wear resistance advantage of silicon carbide, but also compensates for the brittleness of ceramic materials.

Engineers will also carry out “differentiated design” based on the degree of wear of different parts of the pipeline. For example, if the outer arc of the elbow is most severely worn, a thicker silicon carbide lining will be used; If the wear on the inner arc is relatively light, it should be appropriately thinned to ensure durability and avoid material waste.

The application of reaction sintering technology makes silicon carbide pipelines more perfect. By precisely controlling the temperature and raw material ratio, the material can achieve a dense state with almost zero porosity, while introducing graphite components to form a self-lubricating layer. When the fluid flushes the pipeline, the graphite layer forms a protective film, further reducing the friction coefficient, like putting a “lubrication armor” on the pipeline.

From industrial bloodline to green future

In heavy industries such as thermal power, mining, metallurgy, and chemical engineering, pipeline systems are like the “industrial bloodline”, and their reliability is directly related to production safety and efficiency. Traditional metal pipes often need to be replaced within 3 months in strong wear environments, while the service life of silicon carbide wear-resistant pipes can be extended by more than 10 times, greatly reducing the frequency of downtime maintenance.

This long-lasting characteristic also brings significant environmental benefits. Reducing pipeline replacement means reducing steel consumption, and advanced smelting technologies used in the production process (such as ESK method) can recover waste gas for power generation, increasing energy utilization by 20%. In emerging fields such as lithium battery production and environmental protection equipment, the corrosion and wear resistance of silicon carbide pipes are also playing an important role.

When we talk about industrial progress, we often focus on those dazzling high-tech products, but easily overlook the “behind the scenes heroes” such as silicon carbide wear-resistant pipes. It is precisely this innovation that maximizes the properties of basic materials that supports the efficient operation of modern industry. From mines to factories, from high-temperature furnaces to chemical workshops, these silent ‘superhard shields’ are contributing to the safety and sustainability of industrial production in their own way.

Post time: Jul-30-2025