Ha lerōle la moepo le ama phaephe ka lebelo le phahameng, ha lerōle le phahameng la mocheso o ka har'a setsi sa tšepe le ntse le tsoela pele ho hlatsoa lebota le ka hare, le ha tharollo e matla ea asiti setsing sa lik'hemik'hale e senya lebota la phaephe letsatsi le letsatsi - liphaephe tse tloaelehileng tsa tšepe hangata lia lutla kamora likhoeli tse 'maloa feela. Empa ho na le mofuta oa phaephe o ka pholohang "purigatoring ea indasteri" e joalo o sa tsoa kotsi, 'me kephaephe e sa tsofaleng e entsoeng ka silicon carbidee le thepa ea mantlha. Karolo ena e bonahalang e tloaelehile ea indasteri e pata bohlale ba mofuta ofe ba thepa?

Khoutu ea thepa e manganga ho feta tšepe

Pale ea silicon carbide e qalile qetellong ea lekholo la bo19 la lilemo ha bo-rasaense ba sibolla motsoako ona o thata ka phoso ha ba ntse ba leka ho etsa daemane ea maiketsetso. Ha e fumanehe hangata ka tlhaho 'me e tsejoa e le "Moissanite", athe silicon carbide e sebelisoang indastering kajeno e batla e le sehlahisoa sa tlhahiso ea maiketsetso.

Sephiri sa ho etsa liphaephe tsa carbide tsa silicon tse "hanelang tlhahiso" se ho sebopeho sa tsona se ikhethang sa microstructure. Tlas'a microscope ea elektrone, likristale tsa carbide tsa silicon li bontša sebopeho sa tetrahedral se tšoanang le daemane, 'me athomo e 'ngoe le e 'ngoe ea silicon e pota-potiloe ka thata ke liathomo tse 'ne tsa carbon, e leng se etsang marang-rang a khokahano ea covalent e sa robeheng. Sebopeho sena se se fa boima bo latelang daemane feela, ka boima ba Mohs ba 9.5, ho bolelang hore esita le khoholeho e tsoelang pele ea lehlabathe la quartz (boima ba Mohs ba 7) ho thata ho siea mesaletsa.

Se sa tloaelehang le ho feta ke hore silicon carbide ha e thata feela, empa hape e hanela mocheso o phahameng haholo. Mochesong o phahameng oa 1400 ℃, e ntse e ka boloka thepa e tsitsitseng ea mechini, e leng se etsang hore e sebetse hantle maemong a mocheso o phahameng joalo ka ho tsamaisoa ha phofo ea mashala ka har'a lionto tsa tšepe tsa tšepe le ho ntšoa ha slag ea boiler tlhahisong ea motlakase. Ka nako e ts'oanang, e "sireletsa" ho senyeha ha li-acid le alkali tse ngata, 'me khanyetso ena ea mafome e bohlokoa haholo liphaepheng tse matla tsa phetisetso ea acid indastering ea lik'hemik'hale.

Filosofi ea moralo ho eketsa bophelo ba lipeipi ka makhetlo a leshome

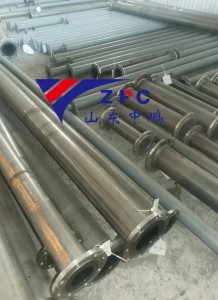

Ho thatafala ho bonolo ha hoa lekana ho sebetsana le tikoloho e rarahaneng ea indasteri. Liphaephe tsa sejoale-joale tse hanelang ho tsofala ha carbide ea silicon li sebelisa meaho e rarahaneng e bohlale: hangata lera le ka ntle ke tšepe e tloaelehileng ea carbon e fanang ka tšehetso ea sebopeho, lera le ka hare ke lesela la ceramic la silicon carbide, 'me liphaephe tse ling li boetse li phuthela fiberglass ka ntle ho ntlafatsa matla ka kakaretso. Moralo ona ha o sebelise feela monyetla oa ho hanyetsa ho tsofala ha carbide ea silicon, empa hape o lefella ho robeha ha thepa ea ceramic.

Baenjiniere ba tla boela ba etse "moralo o fapaneng" ho latela tekanyo ea ho tsofala ha likarolo tse fapaneng tsa phaephe. Mohlala, haeba arc e ka ntle ea setsoe e tsofetse haholo, ho tla sebelisoa lesela le teteaneng la silicon carbide; Haeba ho tsofala ha arc e ka hare ho le bobebe, e lokela ho fokotsoa ka nepo ho netefatsa ho tšoarella le ho qoba tšenyo ea thepa.

Tšebeliso ea theknoloji ea ho sintering ea karabelo e etsa hore liphaephe tsa silicon carbide li be tse phethahetseng haholoanyane. Ka ho laola ka nepo karolelano ea mocheso le thepa e tala, thepa e ka fihlella boemo bo teteaneng bo batlang bo le lefela, ha e ntse e hlahisa likarolo tsa graphite ho etsa lera le itlotsang. Ha mokelikeli o ntša phaephe, lera la graphite le etsa filimi e sireletsang, e fokotsang coefficient ea khohlano haholoanyane, joalo ka ho beha "sehlomo sa ho tlotsa" phaepheng.

Ho tloha lelokong la indasteri ho ea bokamosong bo botala

Liindastering tse boima tse kang matla a mocheso, merafo, tšepe le boenjiniere ba lik'hemik'hale, litsamaiso tsa liphaephe li tšoana le "mali a indasteri", 'me botšepehi ba tsona bo amana ka ho toba le polokeho ea tlhahiso le katleho. Liphaephe tsa tšepe tsa setso hangata li hloka ho nkeloa sebaka nakong ea likhoeli tse 3 libakeng tse matla tsa ho tsofala, ha nako ea tšebeletso ea liphaephe tse sa tsofaleng tsa silicon carbide e ka atolosoa ka makhetlo a fetang 10, e leng se fokotsang haholo makhetlo a tlhokomelo ea nako ea ho se sebetse.

Tšobotsi ena e tšoarellang nako e telele e boetse e tlisa melemo e meholo tikolohong. Ho fokotsa ho nkeloa sebaka ha liphaephe ho bolela ho fokotsa tšebeliso ea tšepe, 'me mahlale a tsoetseng pele a ho qhibilihisa a sebelisoang ts'ebetsong ea tlhahiso (joalo ka mokhoa oa ESK) a ka khutlisa khase e litšila bakeng sa tlhahiso ea motlakase, a eketsa tšebeliso ea matla ka 20%. Masimong a hlahang joalo ka tlhahiso ea betri ea lithium le lisebelisoa tsa tšireletso ea tikoloho, ho hanyetsa ho bola le ho tsofala ha liphaephe tsa silicon carbide le tsona li bapala karolo ea bohlokoa.

Ha re bua ka kgatelopele ya indasteri, hangata re tsepamisa maikutlo hodima dihlahiswa tseo tse kgahlehang tsa theknoloji e hodimo, empa re hlokomoloha habonolo "bahale ba ka morao ho diketsahalo" ba kang diphaephe tse sa tsofaleng tsa silicon carbide. Ke yona ntho ena e ntjha e ntlafatsang thepa ya thepa ya motheo e tshehetsang tshebetso e sebetsang hantle ya indasteri ya sejwalejwale. Ho tloha merafong ho ya difekthering, ho tloha diontong tsa mocheso o phahameng ho ya di-workshop tsa dikhemikhale, 'dithebe tsena tse thata haholo' tse kgutsitseng di kenya letsoho polokehong le botsitsong ba tlhahiso ya indasteri ka tsela ya tsona.

Nako ea poso: Phupu-30-2025