-

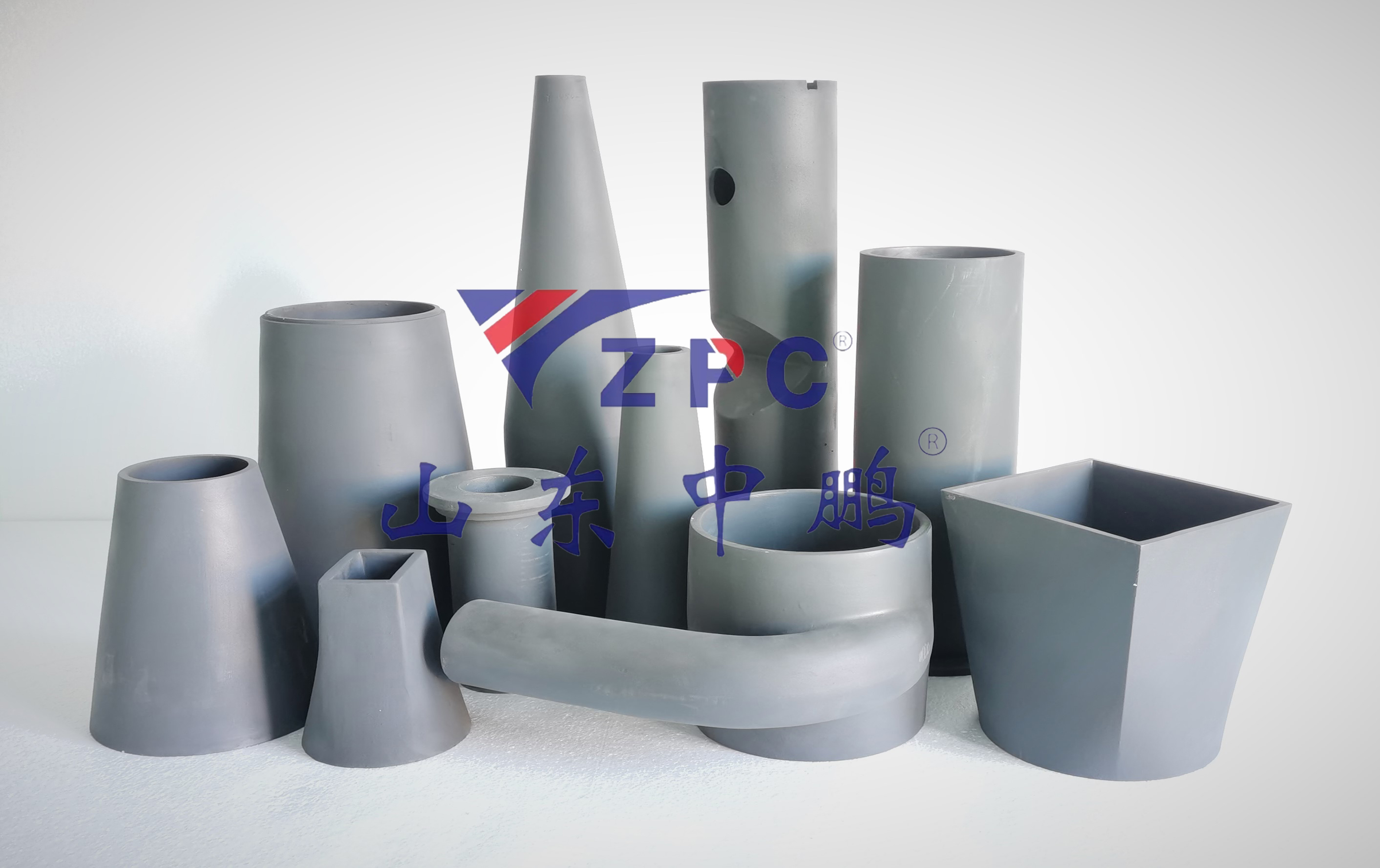

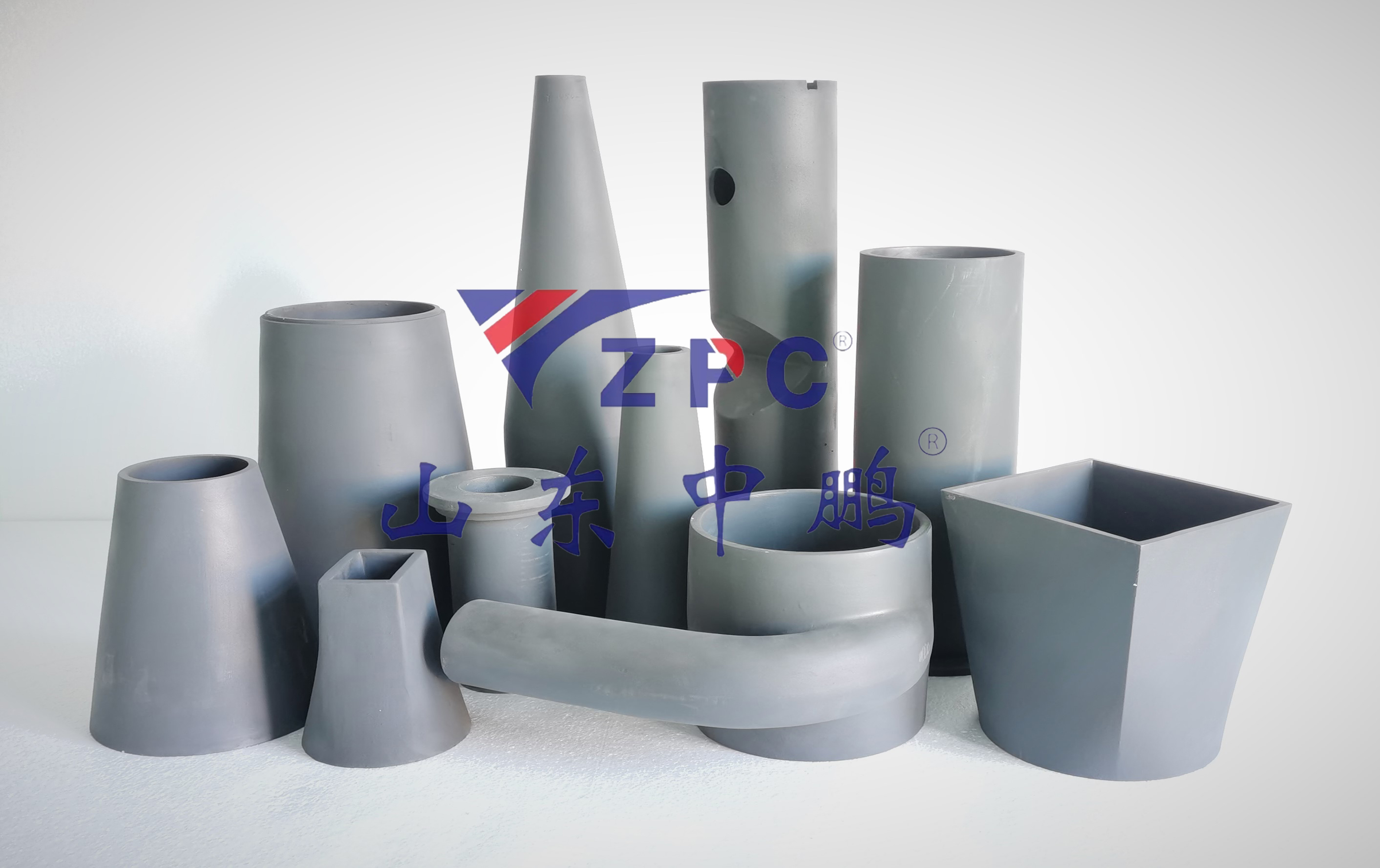

In many industrial production processes, cyclones play a crucial role. During operation, the interior of cyclones is subject to high-speed material erosion. Over time, the inner wall is easily worn, which affects the performance and service life of cyclones. At this point, the lining of the silic...Read more »

-

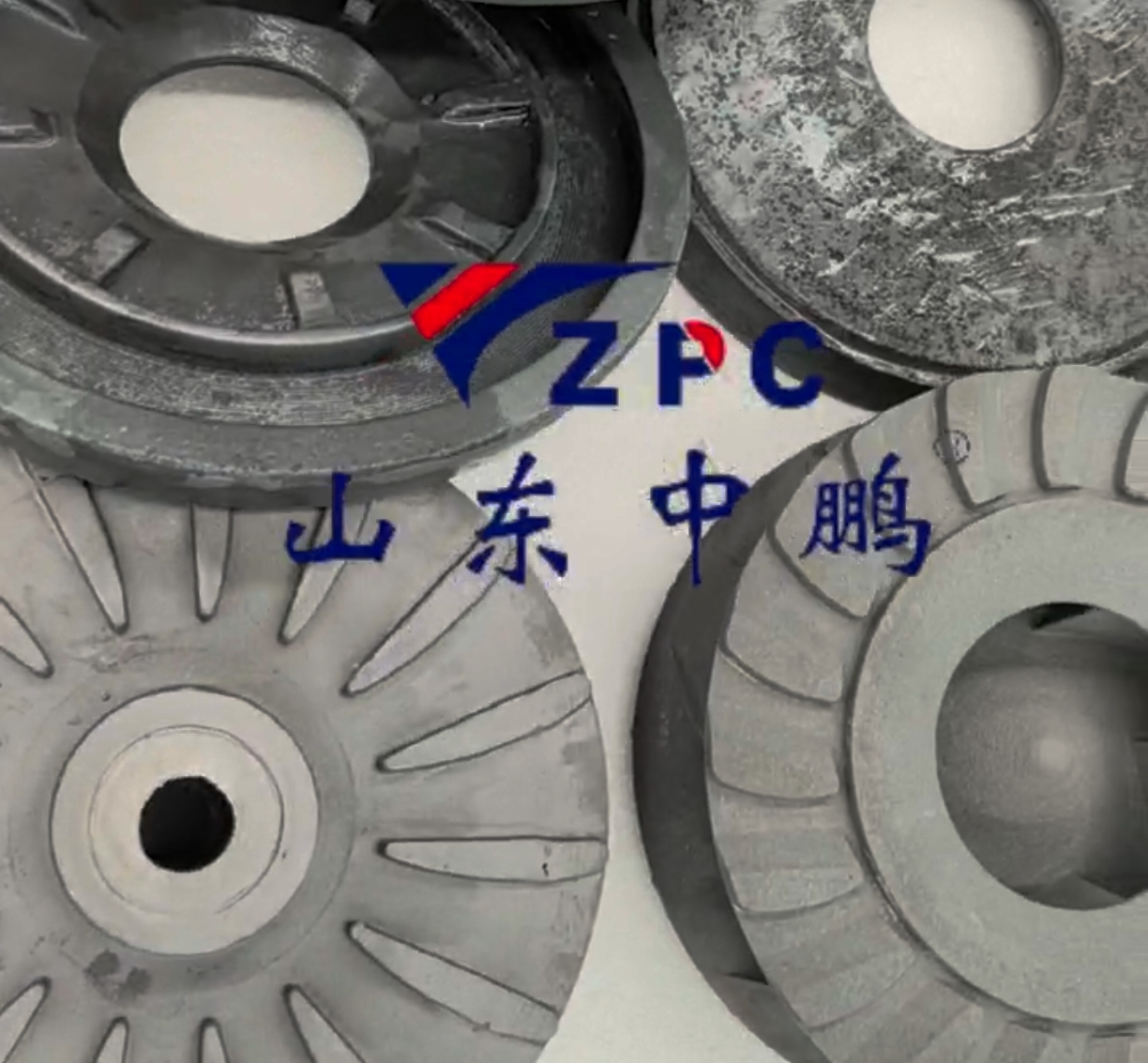

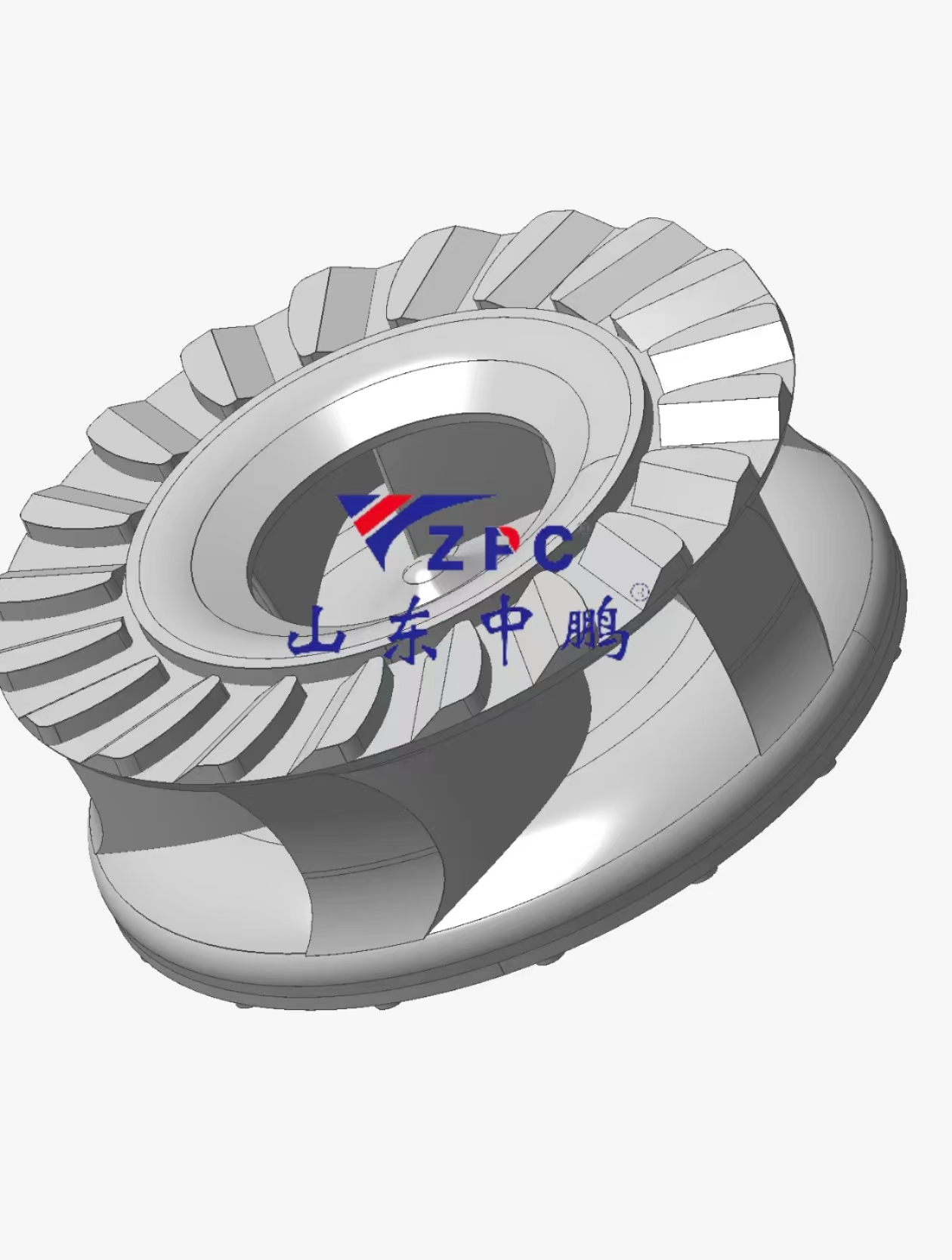

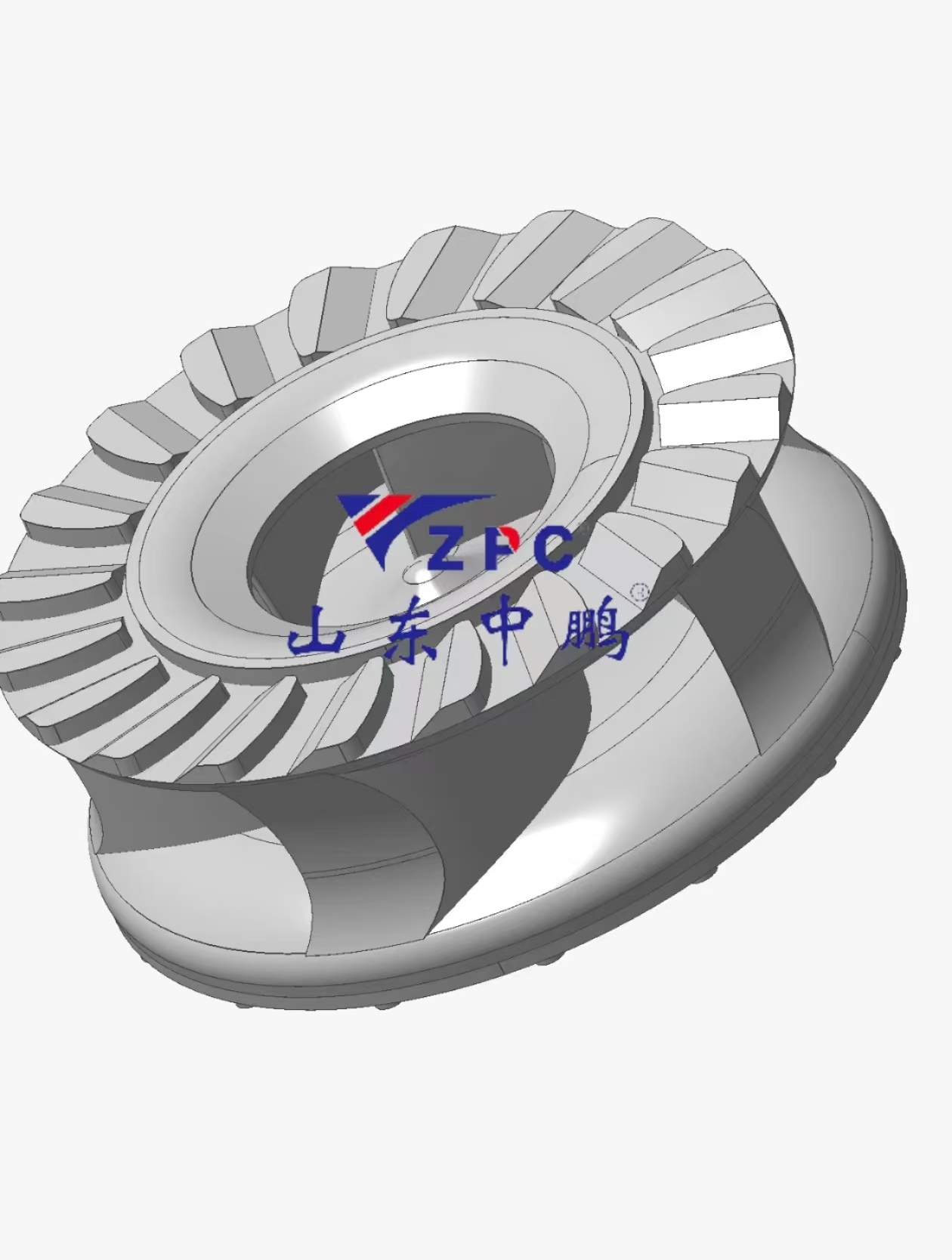

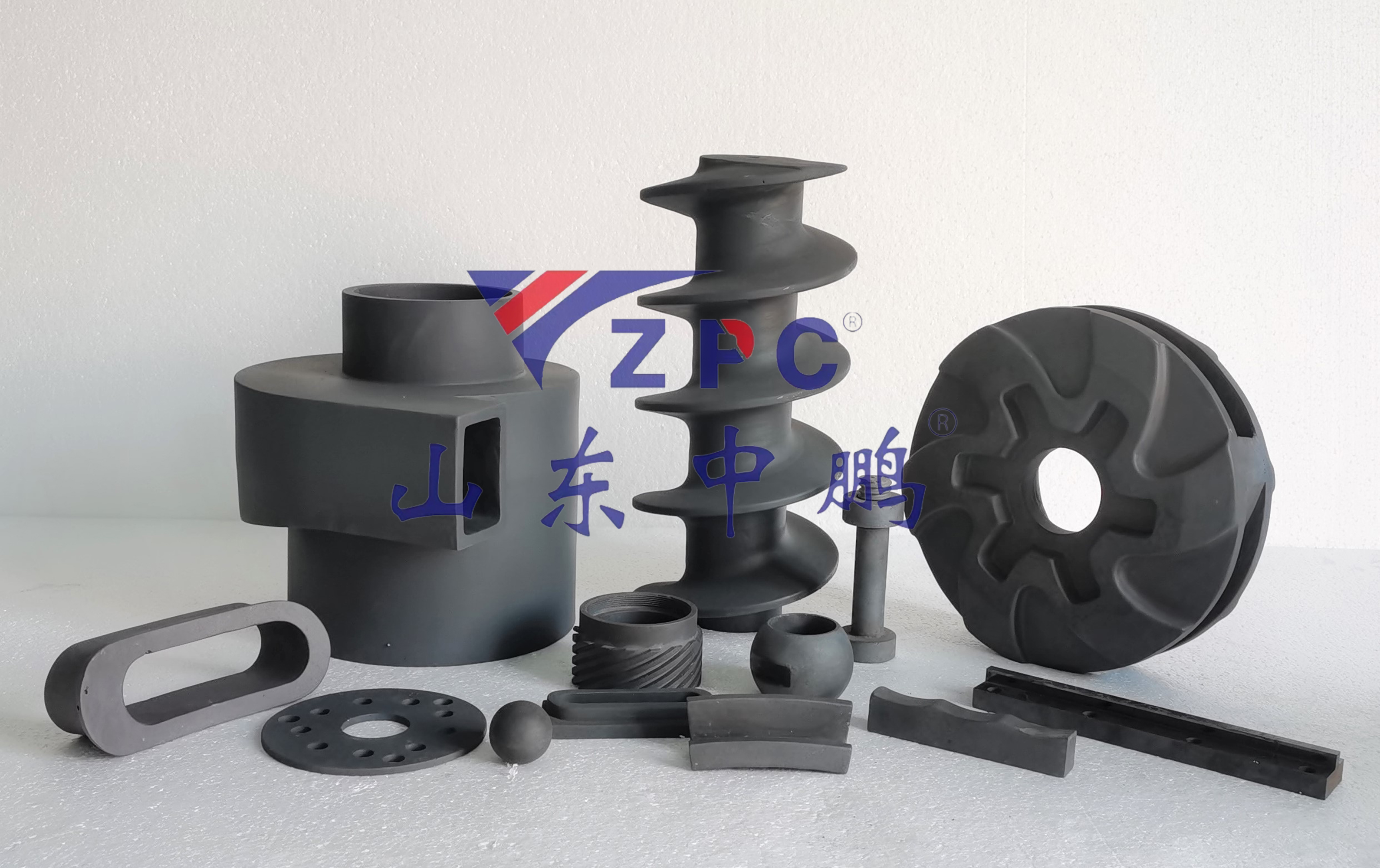

In many industrial production scenarios, it is often necessary to transport liquids containing solid particles, which we call slurry. This demand is extremely common in industries such as mining, metallurgy, power, and chemical engineering. And the slurry pump is the key equipment responsible for...Read more »

-

In the industrial field, transporting liquids containing solid particles is a common but highly challenging task, such as transporting slurry in mining and transporting ash in thermal power generation. The slurry pump plays a crucial role in completing this task. Among numerous slurry pumps, sili...Read more »

-

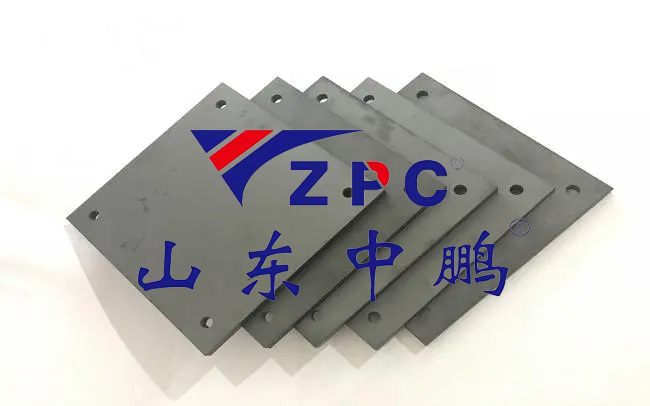

In industrial production, equipment wear and tear is a headache. Wear and tear not only reduces equipment performance, but also increases maintenance costs and downtime, affecting production efficiency. Is there a material that can help equipment resist wear and extend its service life? The answe...Read more »

-

In today’s rapidly developing technology, various new materials continue to emerge, and silicon carbide is one of the shining stars. Especially in the field of protection, silicon carbide plays an irreplaceable and important role in safeguarding our safety due to its unique properties. Sili...Read more »

-

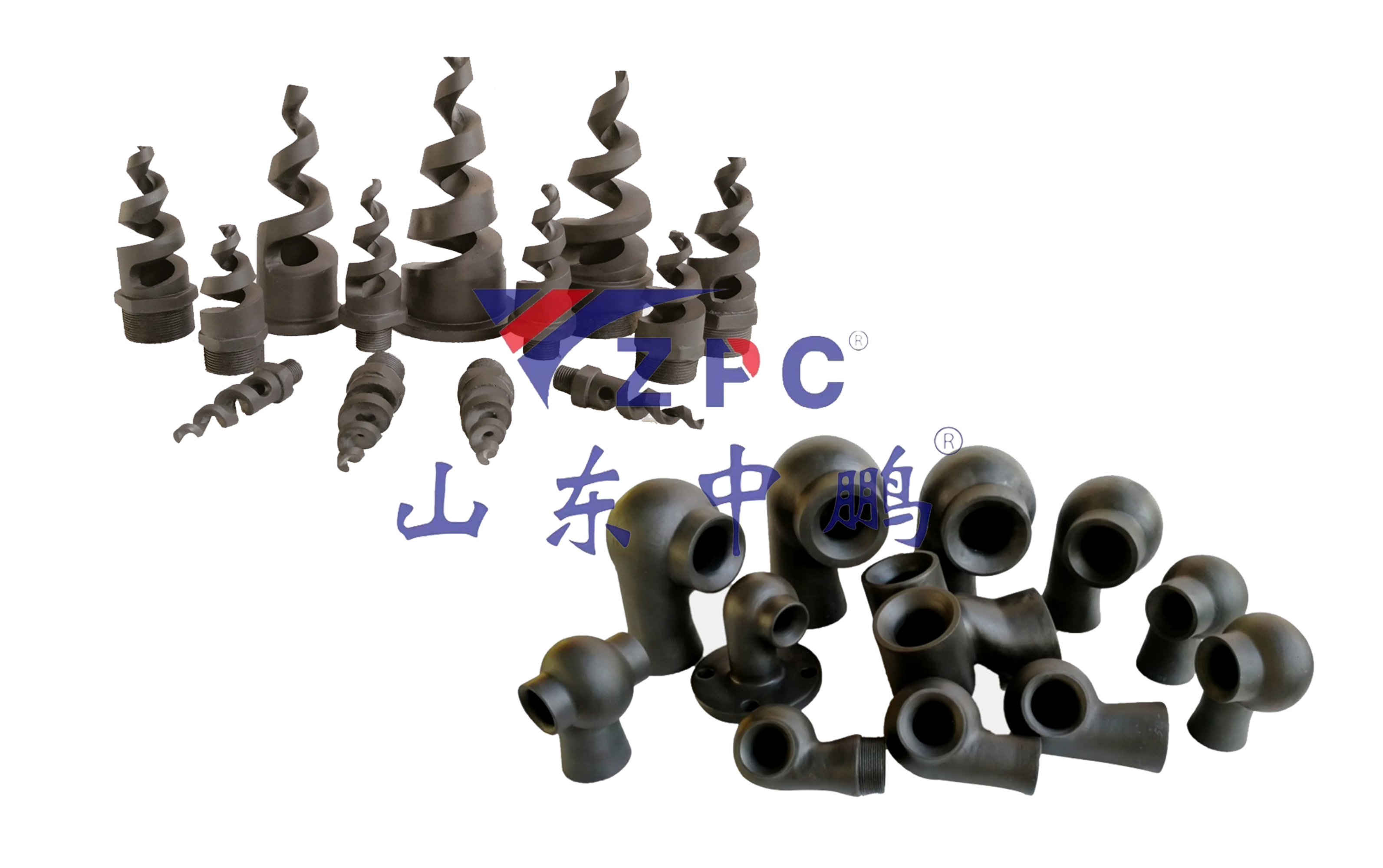

In industrial production, many processes generate sulfur-containing waste gas. If it is directly discharged into the atmosphere, it will not only seriously pollute the environment, but also endanger human health. In order to address this issue, desulfurization technology has emerged, and silicon ...Read more »

-

In the industrial field, equipment often faces various harsh environmental challenges, and wear and tear is one of the major challenges. Wear and tear not only reduces the performance and efficiency of equipment, but may also lead to equipment failures, increasing maintenance costs and downtime. ...Read more »

-

In the industrial field, slurry pumps can be seen everywhere, and they are key equipment to ensure the smooth progress of various production processes. Today, let’s explore the working principle of silicon carbide slurry pump together and see how it plays an important role on the industrial...Read more »

-

In many aspects of industrial production, it is often necessary to transport liquids containing solid particles, which can cause serious wear and tear to the conveying equipment. The slurry pump is a key equipment specifically designed to address this challenge. Traditional slurry pumps often use...Read more »

-

In the vast field of materials science, silicon carbide ceramics have become the “darling” of many high-tech fields due to their excellent properties such as high hardness, high strength, good thermal stability, and chemical stability. From aerospace to semiconductor manufacturing, fr...Read more »

-

In the field of industrial heating, the radiation tube, as a key component, plays an important role in heat transfer and maintaining stable temperature inside the furnace. With the continuous advancement of technology, silicon carbide ceramics have gradually become an ideal material for radiation...Read more »

-

In the development process of modern industry, materials science constantly breaks through and innovates, providing solid support for technological progress in various industries. Among them, reaction sintered silicon carbide ceramics, as a high-performance material, have emerged in many fields d...Read more »

-

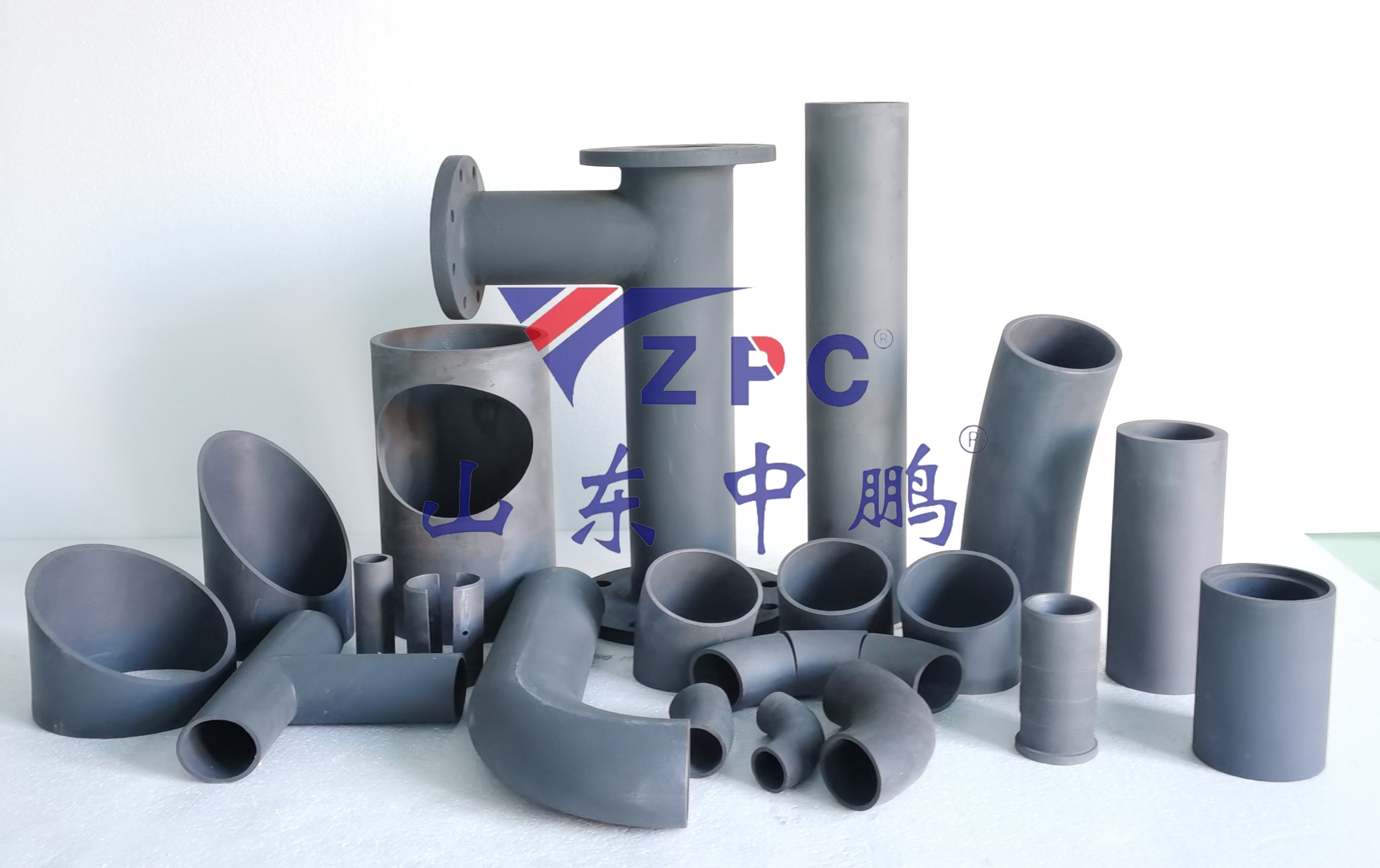

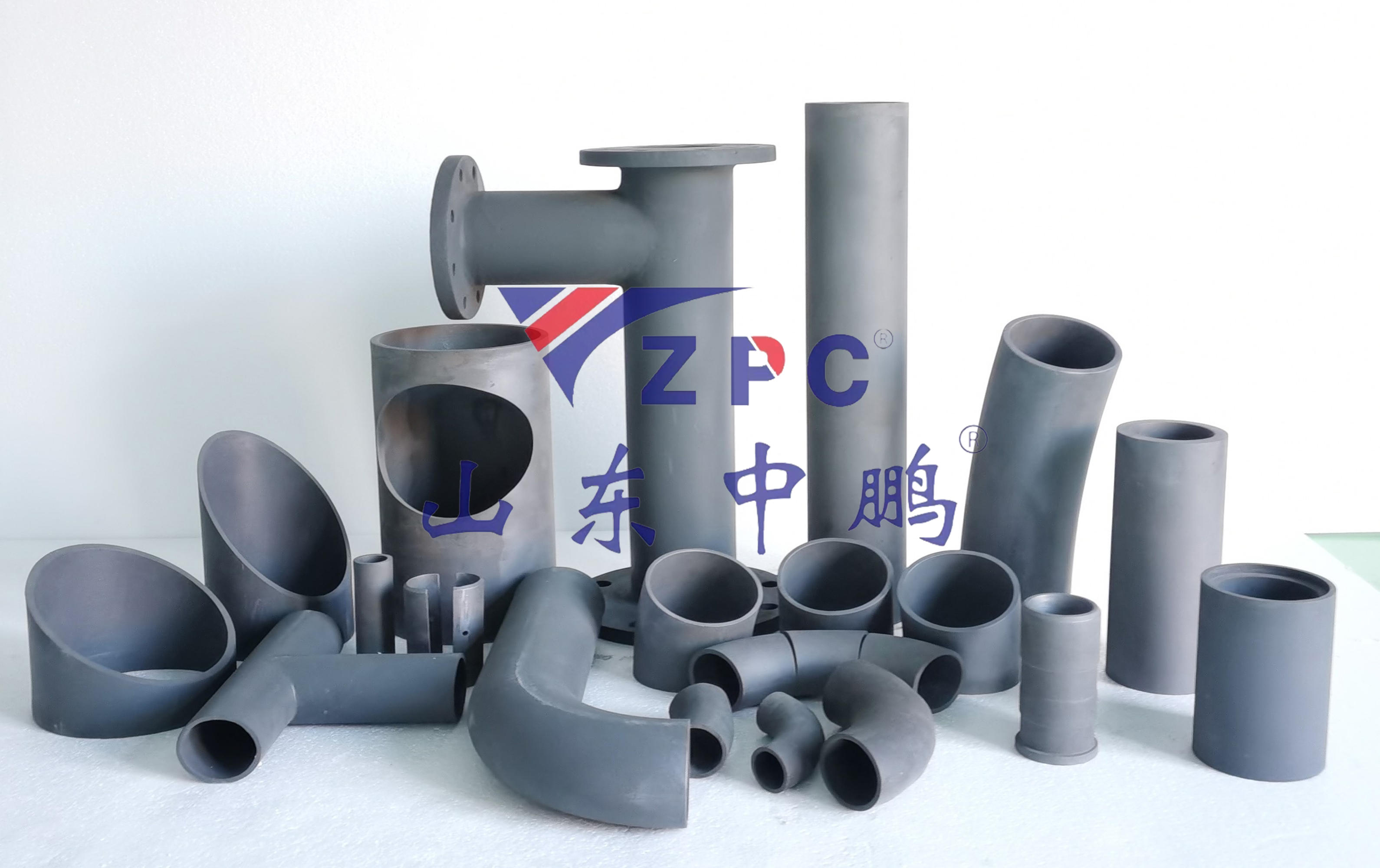

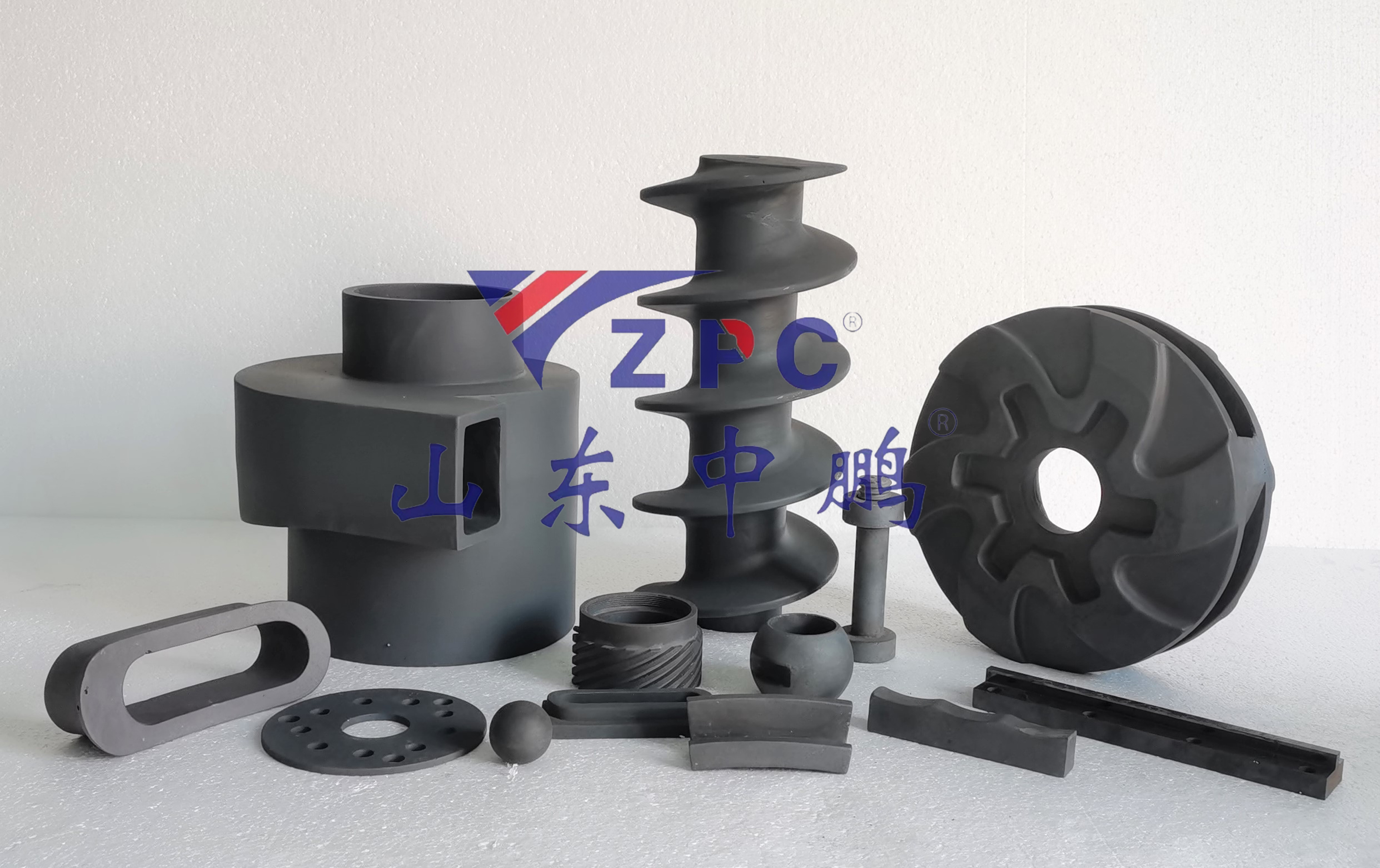

In modern industrial production, equipment faces various harsh working conditions challenges, such as wear and corrosion, which seriously affect the service life and production efficiency of the equipment. The emergence of silicon carbide wear-resistant products provides an effective solution to ...Read more »

-

In the vast world of industrial production, many key links cannot do without the support of high-performance materials. Today, we will introduce a material that plays an important role in traditional industries such as kilns and desulfurization systems – reaction sintered silicon carbide ce...Read more »

-

In the field of modern protection, with the continuous improvement of weapon power, the requirements for bulletproof materials are becoming increasingly stringent. Silicon carbide, a seemingly ordinary but highly energetic material, is gradually emerging as a new favorite in the bulletproof indus...Read more »

-

In modern industrial production, customized silicon carbide shaped parts play an important role and are widely used in various fields. Among them, reaction sintered silicon carbide ceramics have become the preferred material for many customized shaped parts due to their unique performance advanta...Read more »

-

In modern industrial production, many processes cannot do without high-temperature environments, so how to efficiently and stably provide heat has become a key issue. Silicon carbide large radiation tubes are gradually emerging as a new type of industrial heating element, bringing better solution...Read more »

-

In many aspects of industrial production, equipment wear and tear has always been a key factor affecting production efficiency and cost. In order to solve this problem, various wear-resistant materials have emerged, among which silicon carbide wear-resistant lining has gradually become the “...Read more »

-

In industrial production, desulfurization is a crucial environmental task that relates to the improvement of air quality and sustainable development. In the desulfurization system, the desulfurization nozzle plays a key role, and its performance directly affects the desulfurization effect. Today,...Read more »

-

1、 The ‘superpower’ of silicon carbide ceramics (1) High hardness, wear-resistant and durable The hardness of silicon carbide ceramics ranks among the top in the materials industry, second only to diamond. This means that it has super strong wear and scratch resistance. For example...Read more »

-

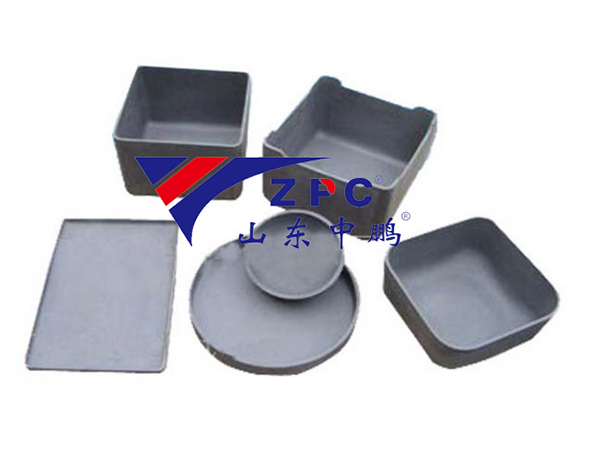

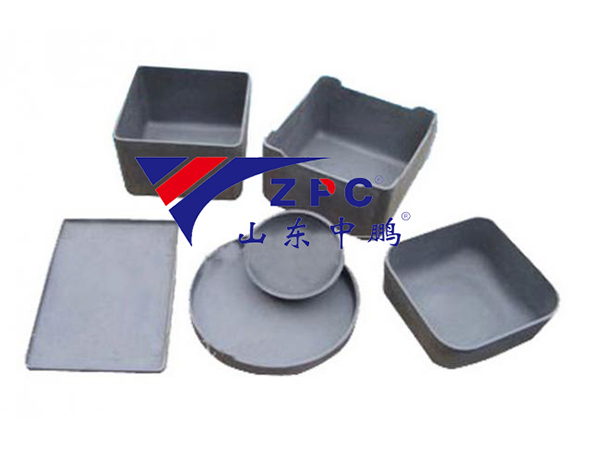

In many high-temperature industrial applications, crucibles play an indispensable role as key containers for holding and heating substances. Silicon carbide ceramic crucibles, with their excellent performance, are gradually becoming the preferred choice in various industries. 1、 What is a silico...Read more »

-

As the “unsung hero” of energy transfer in the industrial field, heat exchangers silently support the operation of industries such as chemical, power, and metallurgy. From air conditioning cooling to rocket engine cooling, its presence is everywhere. However, behind the seemingly simp...Read more »

-

In the field of industrial heating, there is a special type of “energy transporter” that does not require direct contact with flames but can accurately transfer heat. This is the radiation tube known as the “industrial heat engine”. As the core component of modern high-tem...Read more »

-

In industries such as metallurgy, chemical engineering, and new energy, there is a seemingly insignificant but crucial container – the crucible. If traditional crucibles are like “iron rice bowls”, then silicon carbide ceramic crucibles are upgraded versions of “titanium a...Read more »

-

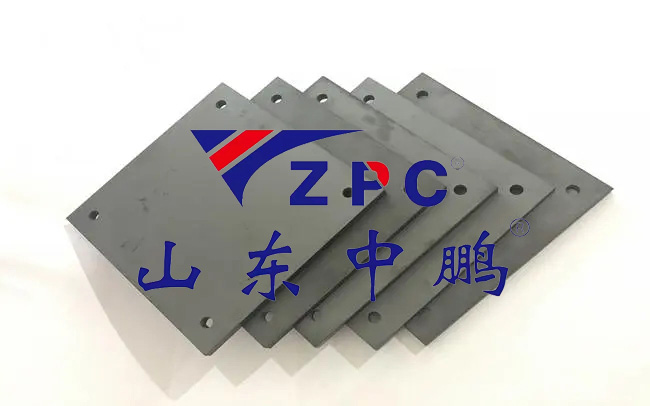

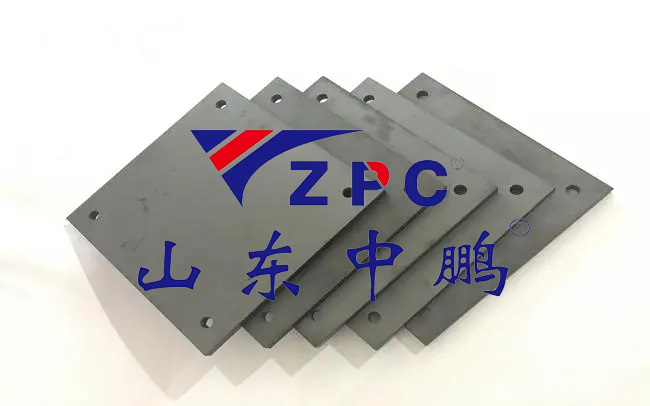

In the world of precision manufacturing, there is a material that silently supports the development of many high-end industries – it is harder than steel, more heat-resistant than graphite, but always maintains a lightweight body. This is silicon carbide ceramic plate, an indispensable R...Read more »