Pamene matope a mgodi agunda payipiyo mofulumira kwambiri, pamene matope otentha kwambiri mu workshop ya zitsulo akupitiriza kutsuka khoma lamkati, ndipo pamene yankho la asidi wamphamvu mu workshop ya mankhwala limawononga khoma la payipi tsiku ndi tsiku - mapaipi wamba achitsulo nthawi zambiri amatuluka patatha miyezi yochepa yokha. Koma pali mtundu wa payipi womwe ungapulumuke mu "purigatoriyo yamafakitale" yotereyi osavulala, ndipo ndipayipi yosatha yopangidwa ndi silicon carbidemonga chinthu chachikulu. Kodi ndi mtundu wanji wa nzeru zakuthupi zomwe gawo la mafakitale looneka ngati lachilendoli limabisa?

Khodi yolimba kwambiri kuposa chitsulo

Nkhani ya silicon carbide inayamba kumapeto kwa zaka za m'ma 1800 pamene asayansi mwangozi anapeza chinthu cholimba ichi pamene ankayesa kupanga diamondi yopangidwa. Ndi chosowa kwambiri m'chilengedwe ndipo chimadziwika kuti "Moissanite", pomwe silicon carbide yomwe imagwiritsidwa ntchito m'mafakitale masiku ano pafupifupi yonse ndi chinthu chopangidwa kuchokera ku kupanga kopangidwa.

Chinsinsi chopangira mapaipi a silicon carbide "osagwira ntchito popanga" chili mu kapangidwe kake kapadera. Pansi pa maikulosikopu ya elekitironi, makristalo a silicon carbide amawonetsa kapangidwe ka tetrahedral kofanana ndi diamondi, ndipo atomu iliyonse ya silicon yozunguliridwa mwamphamvu ndi maatomu anayi a kaboni, ndikupanga netiweki yosasweka ya covalent bond. Kapangidwe kameneka kamapatsa kuuma kwachiwiri kwa diamondi, ndi kuuma kwa Mohs kwa 9.5, zomwe zikutanthauza kuti ngakhale kusokonekera kosalekeza kwa mchenga wa quartz (kuuma kwa Mohs kwa 7) kumakhala kovuta kusiya zizindikiro.

Chosowa kwambiri n'chakuti silicon carbide si yolimba kokha, komanso imapirira kutentha kwambiri. Pa kutentha kwakukulu kwa 1400 ℃, imatha kusungabe mphamvu zokhazikika zamakanika, zomwe zimapangitsa kuti izigwira ntchito bwino pazochitika zotentha kwambiri monga kunyamula ufa wa malasha mu uvuni wachitsulo ndi kutulutsidwa kwa boiler slag popanga mphamvu yotentha. Nthawi yomweyo, "imateteza" kuwonongeka kwa ma acid ndi alkali ambiri, ndipo kukana dzimbiri kumeneku ndi kwamtengo wapatali kwambiri m'mapaipi amphamvu otumizira asidi m'makampani opanga mankhwala.

Nzeru za kapangidwe kake kuti ziwonjezere moyo wa mapaipi kakhumi

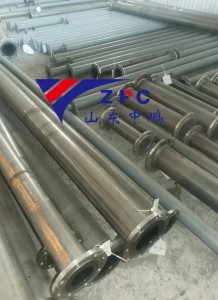

Kuuma kosavuta sikokwanira kuthana ndi malo ovuta a mafakitale. Mapaipi amakono osatha kutopa a silicon carbide amagwiritsa ntchito mapangidwe anzeru: nthawi zambiri gawo lakunja ndi chitsulo cha kaboni chomwe chimapereka chithandizo cha kapangidwe kake, gawo lamkati ndi silicon carbide ceramic lining, ndipo mapaipi ena amakulunganso fiberglass kunja kuti awonjezere mphamvu yonse. Kapangidwe kameneka sikuti kamangogwiritsa ntchito mwayi wokana kutopa wa silicon carbide, komanso kamathandizira kufooka kwa zinthu zadothi.

Mainjiniya adzachitanso "mapangidwe osiyana" kutengera kuchuluka kwa kuwonongeka kwa magawo osiyanasiyana a payipi. Mwachitsanzo, ngati arc yakunja ya chigongono yawonongeka kwambiri, padzagwiritsidwa ntchito silicon carbide yokhuthala; Ngati kuwonongeka kwa arc yamkati kuli kopepuka, kuyenera kuchepetsedwa moyenera kuti zitsimikizire kulimba ndikupewa kutayika kwa zinthu.

Kugwiritsa ntchito ukadaulo wothira zinthu mopupuluma kumapangitsa mapaipi a silicon carbide kukhala abwino kwambiri. Mwa kuwongolera bwino kutentha ndi chiŵerengero cha zinthu zopangira, zinthuzo zimatha kukhala zokhuthala popanda ma porosity, pomwe zimapanga zigawo za graphite kuti zipange gawo lodzipaka lokha. Madzi akamatsuka paipi, gawo la graphite limapanga filimu yoteteza, yomwe imachepetsanso kuchuluka kwa friction coefficient, monga kuyika "zoteteza mafuta" paipiyo.

Kuchokera ku fuko la mafakitale kupita ku tsogolo lobiriwira

Mu mafakitale olemera monga mphamvu ya kutentha, migodi, zitsulo, ndi uinjiniya wa mankhwala, makina a mapaipi ali ngati "magazi a mafakitale", ndipo kudalirika kwawo kumagwirizana mwachindunji ndi chitetezo cha kupanga ndi magwiridwe antchito. Mapaipi achitsulo achikhalidwe nthawi zambiri amafunika kusinthidwa mkati mwa miyezi itatu m'malo ovuta kuvala, pomwe nthawi yogwira ntchito ya mapaipi osagwiritsidwa ntchito ndi silicon carbide imatha kukulitsidwa ndi nthawi zoposa 10, zomwe zimachepetsa kwambiri nthawi yokonza nthawi yogwira ntchito.

Khalidwe lokhalitsa limeneli limabweretsanso ubwino waukulu pa chilengedwe. Kuchepetsa kusintha kwa mapaipi kumatanthauza kuchepetsa kugwiritsa ntchito chitsulo, ndipo ukadaulo wapamwamba wosungunula womwe umagwiritsidwa ntchito popanga (monga njira ya ESK) ukhoza kubwezeretsa mpweya wotayidwa kuti ugwiritsidwe ntchito pamagetsi, ndikuwonjezera kugwiritsa ntchito mphamvu ndi 20%. M'magawo atsopano monga kupanga mabatire a lithiamu ndi zida zoteteza chilengedwe, dzimbiri ndi kukana kuwonongeka kwa mapaipi a silicon carbide zikuchitanso gawo lofunika kwambiri.

Tikamalankhula za kupita patsogolo kwa mafakitale, nthawi zambiri timayang'ana kwambiri zinthu zamakono zokongola, koma mosavuta timanyalanyaza "ngwazi zakumbuyo" monga mapaipi osagwira ntchito a silicon carbide. Ndi luso limeneli lomwe limakulitsa kwambiri katundu wa zipangizo zoyambira zomwe zimathandiza kuti mafakitale amakono azigwira ntchito bwino. Kuyambira migodi mpaka mafakitale, kuyambira ku uvuni wotentha kwambiri mpaka malo ogwirira ntchito mankhwala, 'zishango zolimba kwambiri' izi zikuthandiza kuti kupanga mafakitale kukhale kotetezeka komanso kokhazikika m'njira yawoyawo.

Nthawi yotumizira: Julayi-30-2025