Kana tsvina yemugodhi ichirova pombi nekumhanya kwakanyanya, apo tsvina inopisa zvakanyanya mu workshop yesimbi inoramba ichisuka madziro emukati, uye kana mhinduro ine acid yakasimba mu workshop yemakemikari ichiparadza madziro epombi zuva nezuva - mapaipi esimbi akajairika anowanzo donha mushure memwedzi mishoma chete. Asi kune mhando yemapaipi anogona kurarama mu "purgatory yeindasitiri" yakadaro asina kukuvara, uye ipombi isingapfeki yakagadzirwa nesilicon carbidesechishandiso chikuru. Rudzii rwehungwaru rwezvinhu rwunovigwa nechikamu ichi chinoratidzika sechisiri cheindasitiri?

Kodhi yezvinhu yakaoma kupfuura simbi

Nyaya yesilicon carbide yakatanga mukupera kwezana remakore rechi19 apo masayendisiti akawana chinhu ichi chakaoma netsaona pavaiedza kugadzira dhaimani rekugadzira. Chinowanzika zvikuru uye chinozivikanwa se "Moissanite", nepo silicon carbide inoshandiswa mumaindasitiri nhasi inenge iri chigadzirwa chekugadzirwa kwedhaimani.

Chakavanzika chekugadzira mapaipi esilicon carbide "anodzivirira kugadzirwa" chiri mumagadzirirwo awo akasiyana. Pasi pemaelektron microscope, makristaro esilicon carbide anoratidza chimiro chetetrahedral chakafanana nedhaimani, atomu yega yega yesilicon yakakomberedzwa zvakasimba nemaatomu mana ekabhoni, zvichigadzira network isingaputsike yecovalent bond. Chimiro ichi chinopa kuomarara kwechipiri kune dhaimani, nekuomarara kweMohs kwe9.5, zvinoreva kuti kunyangwe kuputsika kwejecha re quartz (kuomarara kweMohs kwe7) kunonetsa kusiya zviratidzo.

Chinonyanya kushamisa ndechekuti silicon carbide haisi chete yakaoma, asiwo inodzivirira zvakanyanya kupisa kwakanyanya. Pakupisa kwakanyanya kwe1400 ℃, inogona kuramba iine hunhu hwakagadzikana hwemakanika, izvo zvinoita kuti ishande zvakanaka mumamiriro ezvinhu ekupisa kwakanyanya akadai sekutakurwa kwehupfu hwemarasha mumidziyo yesimbi yesimbi uye kuburitswa kweslag mukugadzirwa kwemagetsi ekupisa. Panguva imwe chete, "haipindi" kubva mukuora kwemaacids nemaalkalis mazhinji, uye kuramba uku kwengura kunonyanya kukosha mumapaipi ekutumira acid akasimba muindasitiri yemakemikari.

Uzivi hwekugadzira hunowedzera hupenyu hwemapaipi kagumi

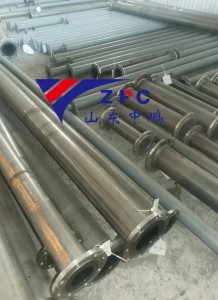

Kuoma kuri nyore hakuna kukwana kuti munhu akwanise kurarama nemamiriro ezvinhu akaomarara emaindasitiri. Mapaipi emazuva ano asingatsvedzeri silicon carbide anoshandisa maumbirwo akangwara: kazhinji chikamu chekunze isimbi yakajairwa yecarbon inopa rutsigiro rwechivakwa, chikamu chemukati isilicon carbide ceramic lining, uye mamwe mapaipi anoputirawo fiberglass kunze kuti awedzere simba rayo. Dhizaini iyi haingoshandisi chete mukana wekudzivirira kusakara kwesilicon carbide, asiwo inotsiva kusasimba kwezvinhu zveceramic.

Mainjiniya achaitawo "dhizaini yakasiyana-siyana" zvichienderana nekusakara kwezvikamu zvakasiyana zvepaipi. Semuenzaniso, kana arc yekunze yegokora yakasakara zvakanyanya, jira rakakora resilicon carbide richashandiswa; Kana kupfeka kwemukati kwearc kwakareruka, kunofanirwa kutetepeswa zvakakodzera kuti kuve nechokwadi chekuti kunogara kwenguva refu uye kudzivirira kurasika kwezvinhu.

Kushandiswa kwetekinoroji ye reaction sintering kunoita kuti mapaipi esilicon carbide ave akakwana. Nekunyatso dzora tembiricha uye huwandu hwezvinhu zvisina kugadzirwa, zvinhu izvi zvinogona kuita kuti pave nehuremu husina kuzara, ukuwo zvichigadzira zvikamu zvegraphite kuti zvigadzire layer inozvizora. Kana mvura ichiyerera mupaipi, layer yegraphite inogadzira firimu rinodzivirira, zvichideredzawo friction coefficient, sekuisa "lubrication armor" papaipi.

Kubva kumhuri yemaindasitiri kusvika kumangwana egirini

Mumaindasitiri makuru akadai sesimba rekupisa, migodhi, simbi, uye mainjiniya emakemikari, masisitimu emapaipi akafanana ne "ropa remuindasitiri", uye kuvimbika kwawo kwakabatana zvakananga nekuchengetedzeka kwekugadzirwa uye kushanda zvakanaka. Mapaipi esimbi echinyakare anowanzo fanirwa kutsiviwa mukati memwedzi mitatu munzvimbo dzakasimba dzekusakara, nepo hupenyu hwemapombi asingatsvedzeri silicon carbide hunogona kuwedzerwa kanopfuura kagumi, zvichideredza zvakanyanya nguva yekugadzirisa.

Hunhu uhwu hunogara kwenguva refu hunounzawo mabhenefiti makuru ezvakatipoteredza. Kuderedza kutsiva mapaipi zvinoreva kuderedza kushandiswa kwesimbi, uye matekinoroji epamusoro ekunyungudutsa anoshandiswa mukugadzirwa (senge nzira yeESK) anogona kudzoreredza gasi rakarasika kuti rigadzirwe magetsi, zvichiwedzera kushandiswa kwesimba ne20%. Muminda mitsva yakadai sekugadzira mabhatiri e lithium nemidziyo yekudzivirira nharaunda, ngura uye kuramba kupfeka kwemapaipi esilicon carbide zviri kuitawo basa rakakosha.

Patinotaura nezvekufambira mberi kwemaindasitiri, tinowanzo tarisa pazvinhu zvinoyevedza zvetekinoroji yepamusoro, asi tisingakwanise kufuratira "magamba ari kumashure" akadai semapaipi asingatsvedzeri silicon carbide. Ndiko kuvandudzwa uku kunowedzera hunhu hwezvinhu zvepakutanga zvinotsigira mashandiro akanaka emaindasitiri emazuva ano. Kubva kumigodhi kusvika kumafekitori, kubva kumaovheni anodziya zvakanyanya kusvika kumaworkshop emakemikari, aya 'mashoo akasimba' ari kubatsira mukuchengetedzeka uye kugara kwenguva refu kwekugadzirwa kwemaindasitiri nenzira yavo.

Nguva yekutumira: Chikunguru-30-2025