Xa uthuli oluvela kwimigodi luchaphazela umbhobho ngesantya esiphezulu, xa uthuli olushushu kakhulu kwindawo yokusebenzela yesinyithi luqhubeka nokuhlamba udonga olungaphakathi, kwaye xa isisombululo se-asidi enamandla kwindawo yokusebenzela yeekhemikhali sidla ngokugqwala udonga lombhobho imihla ngemihla – imibhobho yesinyithi eqhelekileyo idla ngokuvuza emva kweenyanga ezimbalwa kuphela. Kodwa kukho uhlobo lombhobho olunokusinda kwindawo enjalo “yokuhlanjululwa kwemizi-mveliso” lungonzakalanga, kwaye luyintoumbhobho onganyangekiyo owenziwe nge-silicon carbidenjengezinto eziphambili. Loluphi uhlobo lobulumko bezinto eziphathekayo olufihlwa yile nxalenye yemizi-mveliso ebonakala iqhelekile?

Ikhowudi yezinto eziqinileyo kunentsimbi

Ibali le-silicon carbide laqala ngasekupheleni kwenkulungwane ye-19 xa izazinzulu zafumanisa ngempazamo le compound iqinileyo ngelixa zazizama ukwenza idayimani yokwenziwa. Ayiqhelekanga kakhulu kwindalo kwaye yaziwa ngokuba yi-"Moissanite", ngelixa i-silicon carbide esetyenziswa kushishino namhlanje phantse yonke imveliso yokwenziwa kwezinto zokwenziwa.

Imfihlo yokwenza iipayipi ze-silicon carbide "zimelana nokuveliswa" ikwisakhiwo sazo esikhethekileyo. Phantsi kwe-electron microscope, iikristale ze-silicon carbide zibonisa isakhiwo se-tetrahedral esifana nedayimani, apho i-athomu nganye ye-silicon ijikelezwe ngokuqinileyo zii-athomu ezine zekhabhoni, zenza inethiwekhi ye-covalent bond engaqhekekiyo. Esi sakhiwo sinika ubunzima obulandelayo emva kwedayimani, ubunzima be-Mohs obuyi-9.5, oko kuthetha ukuba nokuba ukukhukuliseka okuqhubekayo kwesanti ye-quartz (ubulukhuni be-Mohs obuyi-7) kunzima ukushiya intsalela.

Okungaqhelekanga ngakumbi kukuba i-silicon carbide ayiqinanga nje kuphela, kodwa ikwamelana kakhulu namaqondo obushushu aphezulu. Kumaqondo obushushu aphezulu angama-1400 ℃, isenokugcina iipropati zoomatshini ezizinzileyo, nto leyo eyenza ukuba isebenze kakuhle kwiimeko zobushushu obuphezulu ezifana nokuthuthwa komgubo wamalahle kwiifutha zesinyithi kunye nokukhutshwa kwe-boiler slag ekuveliseni umbane oshushu. Kwangaxeshanye, "ayikhuselekanga" ekukhukulisweni kwe-asidi ezininzi kunye ne-alkalis, kwaye olu xhathiso lokugqwala luxabiseke kakhulu kwiipayipi zokuhambisa i-asidi enamandla kushishino lweekhemikhali.

Ifilosofi yoyilo yokwandisa ubomi bombhobho ngokuphindwe kalishumi

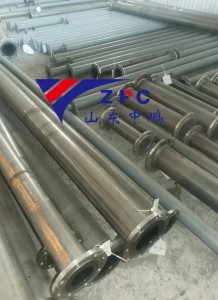

Ubunzima obulula alwanelanga ukumelana neemeko ezinzima zoshishino. Iipayipi zanamhlanje ezingagugiyo ze-silicon carbide zisebenzisa izakhiwo ezikrelekrele ezidityanisiweyo: ngokuqhelekileyo umaleko wangaphandle yintsimbi eqhelekileyo yekhabhoni enika inkxaso yesakhiwo, umaleko wangaphakathi yi-silicon carbide ceramic lining, kwaye ezinye iipayipi zikwasonga i-fiberglass ngaphandle ukuze zomeleze amandla apheleleyo. Olu yilo alusebenzisi nje kuphela inzuzo yokumelana nokuguguleka kwe-silicon carbide, kodwa lukwalungisa ukubuthathaka kwezinto ze-ceramic.

Iinjineli ziya kwenza "uyilo olwahlukileyo" olusekelwe kwinqanaba lokuguguleka kweendawo ezahlukeneyo zombhobho. Umzekelo, ukuba i-arc yangaphandle yengqiniba iguguleke kakhulu, kuya kusetyenziswa i-silicon carbide lining etyebileyo; Ukuba ukuguguleka kwi-arc yangaphakathi kukhaphukhaphu, kufuneka kuncitshiswe ngokufanelekileyo ukuqinisekisa ukuqina nokuphepha inkunkuma yezinto eziphathekayo.

Ukusetyenziswa kwetekhnoloji yokusila i-reaction kwenza imibhobho ye-silicon carbide igqibelele ngakumbi. Ngokulawula ngokuchanekileyo umlinganiselo wobushushu kunye nobungakanani bezinto eziluhlaza, izinto zinokufikelela kwimeko exineneyo ephantse ibe yi-zero porosity, ngelixa kungeniswa izinto ze-graphite ukwenza umaleko ozithambisa ngokwawo. Xa ulwelo lukhupha umbhobho, umaleko we-graphite wenza ifilimu ekhuselayo, enciphisa ngakumbi i-friction coefficient, njengokubeka "isikhuselo sokuthambisa" kumbhobho.

Ukusuka kwigazi lemizi-mveliso ukuya kwikamva eliluhlaza

Kwimizi-mveliso enzima efana namandla obushushu, ukumbiwa kwemigodi, i-metallurgy, kunye nobunjineli beekhemikhali, iinkqubo zemibhobho zifana "negazi lemizi-mveliso", kwaye ukuthembeka kwazo kunxulumene ngokuthe ngqo nokhuseleko kunye nokusebenza kakuhle kwemveliso. Imibhobho yesinyithi yendabuko idla ngokufuna ukutshintshwa zingadlulanga iinyanga ezi-3 kwiindawo ezigugileyo, ngelixa ubomi benkonzo yemibhobho engagugiyo ye-silicon carbide bunokwandiswa ngaphezu kwamaxesha ali-10, nto leyo enciphisa kakhulu amaxesha okugcinwa kwexesha lokungasebenzi.

Olu phawu luhlala ixesha elide luzisa neenzuzo ezibalulekileyo kwindalo esingqongileyo. Ukunciphisa ukutshintshwa kwemibhobho kuthetha ukunciphisa ukusetyenziswa kwentsimbi, kwaye ubuchwepheshe obuphambili bokunyibilikisa obusetyenziswa kwinkqubo yemveliso (njengendlela ye-ESK) bunokubuyisa igesi emdaka ukuze kuvele umbane, nto leyo eyandisa ukusetyenziswa kwamandla ngama-20%. Kwimimandla emitsha efana nemveliso yebhetri ye-lithium kunye nezixhobo zokukhusela indalo, ukugqwala kunye nokumelana nokuguguleka kwemibhobho ye-silicon carbide nako kudlala indima ebalulekileyo.

Xa sithetha ngenkqubela phambili kwezoshishino, sihlala sigxila kwezo mveliso zibalaseleyo zobuchwepheshe obuphezulu, kodwa ngokulula singazijongi “iiqhawe ezingasemva kwemiboniso” ezifana neepayipi ezingagugiyo ze-silicon carbide. Yile ndlela intsha kanye ephucula ngayo iipropati zezinto ezisisiseko ezixhasa ukusebenza kakuhle kweshishini lanamhlanje. Ukususela kwimigodi ukuya kwimizi-mveliso, ukusuka kwiifenitshala ezishushu kakhulu ukuya kwiindawo zokusebenzela iikhemikhali, ezi ‘zikhuselo eziqinileyo’ ezingathethiyo zinegalelo kukhuseleko kunye nokuzinza kwemveliso yezimboni ngendlela yazo.

Ixesha leposi: Julayi-30-2025