Thaum cov tailings slurry ntawm lub mine cuam tshuam rau cov kav dej ntawm qhov ceev ceev, thaum cov slag kub siab hauv lub chaw ua haujlwm metallurgical txuas ntxiv ntxuav phab ntsa sab hauv, thiab thaum cov kua qaub muaj zog hauv lub chaw ua haujlwm tshuaj lom neeg corrodes phab ntsa yeeb nkab hnub tom qab hnub - cov kav dej hlau feem ntau xau tom qab ob peb lub hlis xwb. Tab sis muaj ib hom kav dej uas tuaj yeem muaj sia nyob hauv "kev lag luam purgatory" tsis muaj kev puas tsuaj, thiab nws yog ib qhocov kav dej uas tsis yooj yim hnav ua los ntawm silicon carbideua cov khoom siv tseem ceeb. Cov khoom siv hauv kev lag luam zoo li qub no zais cov khoom siv txawj ntse dab tsi?

Ib qho code khoom siv tawv dua li hlau

Zaj dab neeg ntawm silicon carbide pib thaum xyoo pua 19th thaum cov kws tshawb fawb tau tshawb pom cov khoom siv tawv no thaum sim tsim cov pob zeb diamond. Nws tsis tshua muaj nyob rau hauv xwm thiab hu ua "Moissanite", thaum silicon carbide siv hauv kev lag luam niaj hnub no yuav luag tag nrho yog cov khoom tsim los ntawm kev tsim khoom cuav.

Qhov zais cia rau kev ua cov kav dej silicon carbide kom "tsis yooj yim rau kev tsim khoom" yog nyob rau hauv lawv cov qauv me me tshwj xeeb. Hauv qab lub tshuab hluav taws xob microscope, cov siv lead ua los ntawm silicon carbide qhia txog cov qauv tetrahedral zoo li pob zeb diamond, nrog txhua lub silicon atom puag ncig nruj nreem los ntawm plaub lub carbon atoms, tsim cov network covalent bond tsis tawg. Cov qauv no muab nws qhov nyuaj thib ob tsuas yog pob zeb diamond, nrog Mohs hardness ntawm 9.5, uas txhais tau tias txawm tias kev puas tsuaj tas mus li ntawm cov xuab zeb quartz (Mohs hardness ntawm 7) nyuaj rau tawm cov cim.

Qhov tsis tshua muaj ntxiv yog tias silicon carbide tsis yog tsuas yog tawv xwb, tab sis kuj tiv taus kub heev. Thaum kub txog 1400 ℃, nws tseem tuaj yeem tswj tau cov khoom siv kho tshuab ruaj khov, uas ua rau nws ua tau zoo hauv cov xwm txheej kub xws li kev thauj hmoov thee hauv cov hlau metallurgy blast furnaces thiab boiler slag tawm hauv thermal power generation. Tib lub sijhawm, nws "tiv thaiv" kev yaig ntawm feem ntau cov kua qaub thiab alkalis, thiab qhov kev tiv thaiv corrosion no yog qhov tshwj xeeb tshaj yog hauv cov kav dej xa kua qaub muaj zog hauv kev lag luam tshuaj lom neeg.

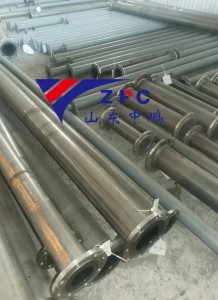

Lub tswv yim tsim qauv kom ua rau lub neej kav dej ntev dua kaum npaug

Kev nyuaj yooj yim tsis txaus los daws cov teeb meem nyuaj hauv kev lag luam. Cov kav dej silicon carbide niaj hnub no siv cov qauv sib xyaw ua ke ntse dua: feem ntau cov txheej sab nraud yog cov hlau carbon uas muab kev txhawb nqa, cov txheej sab hauv yog silicon carbide ceramic lining, thiab qee cov kav dej kuj qhwv fiberglass rau sab nraud kom txhim kho lub zog tag nrho. Qhov kev tsim no tsis yog tsuas yog siv qhov zoo ntawm kev tiv thaiv kev hnav ntawm silicon carbide, tab sis kuj them rau qhov tsis zoo ntawm cov khoom siv ceramic.

Cov kws ua choj kuj tseem yuav ua "kev tsim qauv sib txawv" raws li qib kev hnav ntawm ntau qhov ntawm cov kav dej. Piv txwv li, yog tias sab nraud ntawm lub luj tshib raug hnav hnyav tshaj plaws, yuav siv cov ntaub silicon carbide tuab dua; Yog tias qhov hnav ntawm sab hauv lub arc tsis hnyav heev, nws yuav tsum tau ua kom nyias kom ntseeg tau tias muaj zog thiab tsis txhob pov tseg cov khoom siv.

Kev siv cov thev naus laus zis sintering ua rau cov kav dej silicon carbide zoo meej dua. Los ntawm kev tswj qhov kub thiab qhov sib piv ntawm cov khoom siv raw, cov khoom siv tuaj yeem ua tiav lub xeev ntom nrog yuav luag xoom porosity, thaum qhia cov khoom graphite los tsim cov txheej txheem nws tus kheej lubricating. Thaum cov kua dej ntws tawm hauv cov kav dej, cov txheej graphite tsim cov zaj duab xis tiv thaiv, txo qhov sib txhuam coefficient, zoo li muab "lubrication armor" rau ntawm cov kav dej.

Los ntawm cov ntshav lag luam mus rau yav tom ntej ntsuab

Hauv cov lag luam hnyav xws li lub zog thermal, kev khawb av, metallurgy, thiab chemical engineering, cov kav dej zoo li "cov ntshav hauv kev lag luam", thiab lawv qhov kev ntseeg tau ncaj qha cuam tshuam nrog kev nyab xeeb thiab kev ua haujlwm zoo. Cov kav hlau ib txwm muaj feem ntau yuav tsum tau hloov pauv hauv 3 lub hlis hauv cov chaw muaj zog hnav, thaum lub neej ua haujlwm ntawm cov kav dej silicon carbide hnav-resistant tuaj yeem ntev dua 10 zaug, txo qhov zaus ntawm kev saib xyuas lub sijhawm tsis ua haujlwm.

Qhov cwj pwm ntev no kuj coj cov txiaj ntsig zoo rau ib puag ncig. Kev txo cov kav dej hloov pauv txhais tau tias txo kev siv hlau, thiab cov thev naus laus zis smelting siab heev siv hauv cov txheej txheem tsim khoom (xws li ESK txoj kev) tuaj yeem rov qab tau cov roj pov tseg rau kev tsim hluav taws xob, ua rau kev siv hluav taws xob ntau ntxiv 20%. Hauv cov teb tshiab xws li kev tsim roj teeb lithium thiab cov khoom siv tiv thaiv ib puag ncig, kev xeb thiab hnav tsis kam ntawm cov kav dej silicon carbide kuj tseem ua lub luag haujlwm tseem ceeb.

Thaum peb tham txog kev nce qib hauv kev lag luam, peb feem ntau tsom mus rau cov khoom siv thev naus laus zis zoo nkauj, tab sis yooj yim tsis quav ntsej txog "cov phab ej tom qab" xws li cov kav dej silicon carbide uas tiv taus kev hnav. Nws yog qhov kev tsim kho tshiab no uas ua kom cov khoom siv ntawm cov ntaub ntawv yooj yim tshaj plaws uas txhawb nqa kev ua haujlwm zoo ntawm kev lag luam niaj hnub. Los ntawm cov chaw tsuas mus rau cov chaw tsim khoom, los ntawm cov cub tawg kub mus rau cov chaw ua haujlwm tshuaj lom neeg, cov 'superhard shields' uas ntsiag to no tau pab txhawb rau kev nyab xeeb thiab kev ruaj khov ntawm kev tsim khoom lag luam hauv lawv txoj kev.

Lub sijhawm tshaj tawm: Lub Xya Hli-30-2025