Lapho udaka lwezimayini luthinta ipayipi ngesivinini esikhulu, lapho i-slag enezinga eliphezulu lokushisa endaweni yokusebenzela yensimbi iqhubeka nokugeza udonga lwangaphakathi, nalapho isixazululo se-asidi esiqinile endaweni yokusebenzela yamakhemikhali sigqwala udonga lwamapayipi usuku nosuku - amapayipi ensimbi avamile avame ukuvuza ngemva kwezinyanga ezimbalwa kuphela. Kodwa kunohlobo oluthile lwepayipi olungaphila “esihlanzweni sezimboni” ngaphandle kokulimala, futhi siyisihlanzo.ipayipi elingagugi elenziwe nge-silicon carbidenjengento ewumgogodla. Hlobo luni lobuhlakani obubonakalayo le ngxenye yemboni ebonakala ijwayelekile?

Ikhodi yempahla enenkani kunensimbi

Indaba ye-silicon carbide yaqala ngasekupheleni kwekhulu le-19 lapho ososayensi bethola ngephutha le nhlanganisela eqinile ngenkathi bezama ukwenza idayimane lokwenziwa. Kuyinto engavamile kakhulu emvelweni futhi yaziwa ngokuthi "i-Moissanite", kuyilapho i-silicon carbide esetshenziswa embonini namuhla cishe iwumkhiqizo wokwenziwa kokwenziwa.

Imfihlo yokwenza amapayipi e-silicon carbide "amelane nokukhiqizwa" ilele ku-microstructure yawo eyingqayizivele. Ngaphansi kwesibonakhulu se-electron, amakristalu e-silicon carbide abonisa isakhiwo se-tetrahedral esifana nedayimane, ne-athomu ngayinye ye-silicon ezungezwe ngokuqinile ama-athomu ekhabhoni amane, akha inethiwekhi yebhondi eqinile enganqamuki. Lesi sakhiwo sinikeza ubulukhuni okwesibili kuphela kwedayimane, ngobulukhuni be-Mohs be-9.5, okusho ukuthi ngisho nokuguguleka okuqhubekayo kwesihlabathi se-quartz (ukuqina kwe-Mohs ye-7) kunzima ukushiya iminonjana.

Okungavamile nakakhulu ukuthi i-silicon carbide ayinzima nje kuphela, kodwa futhi imelana kakhulu nokushisa okuphezulu. Emazingeni okushisa aphezulu angu-1400 ℃, isengakwazi ukugcina izakhiwo ezinzile zemishini, okuyenza isebenze kahle ezimweni ezisezingeni eliphezulu ezifana nokuthuthwa kwempushana yamalahle ezifuleni zensimbi eziqhumayo zensimbi kanye nokukhishwa kwe-boiler slag ekukhiqizeni amandla ashisayo. Ngesikhathi esifanayo, “akuvimbeli” ukuguguleka kwama-asidi amaningi nama-alkali, futhi lokhu kumelana nokugqwala kuyigugu ikakhulukazi kumapayipi okudluliselwa kwe-asidi eqinile embonini yamakhemikhali.

Ifilosofi yokuklama yokwandisa ubude bokuphila kwepayipi ngokuphindwe kashumi

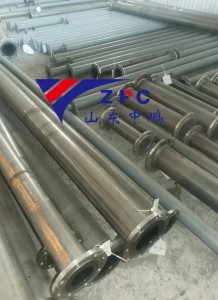

Ubulukhuni obulula akwanele ukubhekana nezimo eziyinkimbinkimbi zezimboni. Amapayipi esimanje e-silicon carbide amelana nokugqokwa asebenzisa izakhiwo eziyinhlanganisela ehlakaniphile: ngokuvamile ungqimba olungaphandle luyinsimbi evamile ye-carbon ehlinzeka ngokusekelwa kwesakhiwo, ungqimba lwangaphakathi ulwelwesi lwe-silicon carbide ceramic, kanti amanye amapayipi aphinde asonge i-fiberglass ngaphandle ukuze kuthuthukiswe amandla. Lo mklamo awugcini nje ngokunikeza inzuzo yokumelana nokugqokwa kwe-silicon carbide, kodwa futhi unxephezela ukonakala kwezinto zobumba.

Onjiniyela bazophinde benze “idizayini ehlukile” ngokususelwa kuzinga lokuguga kwezingxenye ezahlukahlukene zepayipi. Isibonelo, uma i-arc yangaphandle yendololwane igqoke kakhulu, kuzosetshenziswa ulwelwesi olushubile lwe-silicon carbide; Uma ukuguga kwe-arc yangaphakathi kukhanya uma kuqhathaniswa, kufanele kuncishiswe ngokufanelekile ukuze kuqinisekiswe ukuqina nokugwema ukumosheka kwezinto.

Ukusetshenziswa kobuchwepheshe be-reaction sintering kwenza amapayipi e-silicon carbide aphelele kakhulu. Ngokulawula kahle izinga lokushisa nesilinganiso sempahla eluhlaza, okokusebenza kungafinyelela esimweni esiminyene cishe nge-zero porosity, kuyilapho yethula izingxenye zegraphite ukuze zakhe ungqimba oluzigcoba ngokwalo. Lapho uketshezi lugudluza ipayipi, ungqimba lwe-graphite lwakha ifilimu evikelayo, iphinde inciphise i-coefficient yokungqubuzana, njengokufaka “isivikelo sokuthambisa” epayipini.

Kusukela ku-industrial bloodline kuya kwekusasa eliluhlaza

Ezimbonini ezinzima ezifana namandla ashisayo, izimayini, i-metallurgy, nobunjiniyela bamakhemikhali, izinhlelo zamapayipi zifana "negazi lezimboni", futhi ukwethembeka kwazo kuhlobene ngokuqondile nokuphepha nokusebenza kahle kokukhiqiza. Amapayipi ensimbi endabuko ngokuvamile adinga ukushintshwa phakathi nezinyanga ezi-3 ezindaweni zokuguga eziqinile, kuyilapho impilo yesevisi yamapayipi amelana nokugqokwa kwe-silicon carbide inganwetshwa izikhathi ezingaphezu kweziyi-10, kunciphisa kakhulu imvamisa yokulungiswa kwesikhathi sokuphumula.

Lesi sici esihlala isikhathi eside siletha izinzuzo ezibalulekile zemvelo. Ukunciphisa ukushintshwa kwamapayipi kusho ukunciphisa ukusetshenziswa kwensimbi, kanye nobuchwepheshe bokuncibilikisa obuthuthukisiwe obusetshenziswa enqubweni yokukhiqiza (njengendlela ye-ESK) bungabuyisa igesi engcolile ukuze kuphehlwe ugesi, kukhuphule ukusetshenziswa kwamandla ngama-20%. Ezindaweni ezisafufusa ezifana nokukhiqizwa kwebhethri ye-lithium kanye nemishini yokuvikela imvelo, ukugqwala nokumelana nokugqoka kwamapayipi e-silicon carbide nakho kudlala indima ebalulekile.

Uma sikhuluma ngenqubekelaphambili yezimboni, sivamise ukugxila kuleyo mikhiqizo ecwebezelayo yobuchwepheshe obuphezulu, kodwa singanaki kalula “amaqhawe angemuva” anjengamapayipi amelana ne-silicon carbide. Yilokhu kanye okuqanjwe kabusha okukhulisa izakhiwo zezinto eziyisisekelo ezisekela ukusebenza kahle kwemboni yesimanje. Kusukela ezimayini kuya ezimbonini, kusukela eziko lokushisa eliphezulu kuya ezindaweni zokucobelelana ngolwazi zamakhemikhali, lezi 'zihlangu eziqinile' ezithulile zineqhaza ekuphepheni nasekusimameni kokukhiqizwa kwezimboni ngendlela yazo.

Isikhathi sokuthumela: Jul-30-2025