1. Ukumelana Nokugqwala

Ama-nozzle e-FGDzisebenza ezindaweni ezibola kakhulu eziqukethe ama-sulfur oxides, ama-chloride, namanye amakhemikhali anolaka. I-Silicon carbide (SiC) ceramic ikhombisa ukumelana nokubola okumangalisayo ngokulahlekelwa okungaphansi kuka-0.1% kwesisindo kuzixazululo ze-pH 1-14 (ngokuhlolwa kwe-ASTM C863). Uma kuqhathaniswa nensimbi engagqwali (PREN 18-25) kanye nama-nickel alloys (PREN 30-40), i-SiC igcina ubuqotho besakhiwo ngaphandle kokufaka imigodi noma ukucindezela ukuqhekeka kokubola ngisho naku-acids egxilile emazingeni okushisa aphezulu.

2. Ukuzinza Kwezinga Lokushisa Eliphezulu

Izinga lokushisa lokusebenza ezinhlelweni zokususa i-flue gas ezimanzi ngokuvamile lisukela ku-60-80°C kanye nama-spikes adlula i-120°C. I-SiC ceramic igcina u-85% wamandla ayo okushisa kwegumbi ku-1400°C, idlula i-alumina ceramics (ilahlekelwa amandla angu-50% ngo-1000°C) kanye nezinsimbi ezingamelani nokushisa. Ukuqhuba kwayo ukushisa (120 W/m·K) kwenza ukushisa kusebenze kahle, kuvimbele ukwakheka kokucindezeleka kokushisa.

3. Ukumelana Nokugqokwa

Ngobunzima be-Vickers obungu-28 GPa kanye nokuqina kokuqhekeka okungu-4.6 MPa·m¹/², i-SiC ikhombisa ukumelana okukhulu kokuguguleka ngokumelene nezinhlayiya zomlotha ompukane (Mohs 5-7). Ukuhlolwa kwensimu kubonisa ukuthi ama-nozzle e-SiC agcina ukuguguleka okungu-<5% ngemva kwamahora okusebenza angu-20,000, uma kuqhathaniswa nokuguguleka okungu-30-40% kuma-nozzle e-alumina kanye nokwehluleka okuphelele kwezinsimbi ezimbozwe nge-polymer zingakapheli amahora angu-8,000.

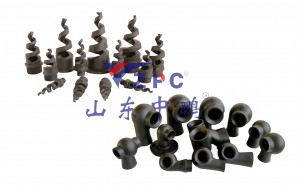

4. Izici Zokugeleza

Ubuso obungamanzi be-SiC eboshiwe yokusabela (i-contact angle >100°) buvumela ukusabalala okunembile kwe-slurry ngamanani e-CV <5%. Ubuso bayo obubushelelezi kakhulu (Ra 0.2-0.4μm) bunciphisa ukwehla kwengcindezi ngo-15-20% uma kuqhathaniswa nama-nozzle ensimbi, kuyilapho kugcinwa ama-coefficients okukhipha azinzile (±1%) ngesikhathi sokusebenza isikhathi eside.

5. Ukulungiswa Okulula

Ukungangeni kwamakhemikhali kwe-SiC kuvumela izindlela zokuhlanza ezinolaka ezifaka:

- Indiza yamanzi enomfutho ophezulu (kufika kumabha angu-250)

- Ukuhlanza kwe-Ultrasonic ngezixazululo ze-alkaline

- Ukuhlanza ngomusi ku-150°C

Ngaphandle kwengozi yokuwohloka kobuso okuvamile kuma-nozzles ensimbi afakwe i-polymer noma ambozwe nge-coated.

6. Ezomnotho Zomjikelezo Wempilo

Nakuba izindleko zokuqala zama-nozzle e-SiC ziphakeme ngama-2-3× kunensimbi engagqwali ejwayelekile engu-316L, impilo yazo yesevisi yeminyaka engu-8-10 (uma kuqhathaniswa neminyaka engu-2-3 yezinsimbi) inciphisa imvamisa yokushintsha ngo-70%. Izindleko zobunikazi eziphelele zibonisa ukonga okungu-40-60% esikhathini seminyaka eyi-10, ngaphandle kwesikhathi sokungasebenzi sokulungisa endaweni.

7. Ukuhambisana Kwemvelo

I-SiC ikhombisa ukusebenza okungenakuqhathaniswa ezimweni ezimbi kakhulu:

- Ukumelana nokufuthwa kukasawoti: ushintsho lwesisindo esingu-0% ngemuva kokuhlolwa kwe-ASTM B117 kwamahora angu-5000

- Ukusebenza kwephuzu le-acid dew: Kumelana nomphunga we-H2SO4 ongu-160°C

- Ukumelana nokushaqeka kokushisa: Kusinda emijikelezweni yokucima engu-1000°C →25°C

8. Izakhiwo Ezingakhulisi Ukukhula

Isakhiwo se-athomu se-covalent se-SiC sakha indawo engaphenduli kahle enamazinga okukala angama-80% aphansi kunezinye izindlela zensimbi. Izifundo ze-Crystallographic zembula ukuthi ama-calcite kanye nama-gypsum deposits akha izibopho ezibuthakathaka (ukunamathela <1 MPa) ku-SiC uma kuqhathaniswa ne->5 MPa ezinsimbini, okwenza kube lula ukususwa ngomshini.

Isiphetho Sobuchwepheshe

I-silicon carbide ceramic ivela njengokukhetha okuhle kwezinto zokwakha ama-nozzles e-FGD ngokuhlola ukusebenza okuphelele:

- Impilo yesevisi ende eyi-10x kunezinye izindlela zensimbi

- Ukwehla okungu-92% ekunakekelweni okungahleliwe

- Ukuthuthukiswa okungu-35% ekusebenzeni kahle kokususwa kwe-SO2 ngokusebenzisa amaphethini okufafaza ahambisanayo

- Ukuthobela ngokugcwele amazinga okukhishwa kwegesi e-EPA 40 CFR Ingxenye 63

Ngezindlela zokukhiqiza ezithuthukayo ezifana nokusinta kwesigaba soketshezi kanye nokugqoka kwe-CVD, ama-nozzle esizukulwane esilandelayo e-SiC afinyelela ukuqedwa kobuso obungaphansi kwe-micron kanye nama-geometri ayinkimbinkimbi ayengatholakali ngaphambili ku-ceramics. Lokhu kuthuthuka kobuchwepheshe kubeka i-silicon carbide njengento ekhethwayo yezinhlelo zokuhlanza igesi yoketshezi yesizukulwane esilandelayo.

Isikhathi sokuthunyelwe: Mashi-20-2025