1. Ukumelana nokugqwala

Iimpumlo ze-FGDzisebenza kwiindawo ezinobungozi kakhulu eziqulethe i-sulfur oxides, ii-chloride, kunye nezinye iikhemikhali ezirhabaxa. I-Silicon carbide (SiC) ceramic ibonisa ukumelana nokugqwala okugqwesileyo kunye nokulahleka kobunzima obungaphantsi kwe-0.1% kwizisombululo ze-pH 1-14 (ngokovavanyo lwe-ASTM C863). Xa kuthelekiswa nentsimbi engatyiwayo (PREN 18-25) kunye nee-nickel alloys (PREN 30-40), i-SiC igcina ukuqina kwesakhiwo ngaphandle kokuphazamisa okanye ukuqhekeka kokugqwala nokuba kwii-acids ezixineneyo kumaqondo obushushu aphezulu.

2. Uzinzo lobushushu obuphezulu

Amaqondo obushushu asebenzayo kwiinkqubo zokususa i-flue gas desulfurization aqhele ukuba phakathi kwama-60-80°C kunye nee-spikes ezingaphezulu kwama-120°C. I-SiC ceramic igcina ama-85% amandla ayo obushushu begumbi kwi-1400°C, iphumelela ngaphezu kwe-alumina ceramics (ilahlekelwa ngamandla angama-50% nge-1000°C) kunye neentsimbi ezimelana nobushushu. Ukuqhuba kwayo ubushushu (120 W/m·K) kwenza ukuba ubushushu buchitheke ngokufanelekileyo, kuthintele ukwakheka koxinzelelo lobushushu.

3. Ukumelana nokunxitywa

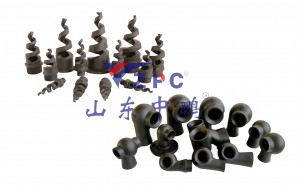

Ngobunzima beVickers obuyi-28 GPa kunye nokuqina kokuqhekeka kwe-4.6 MPa·m¹/², iSiC ibonakalisa ukumelana nokukhukuliseka okuphezulu ngokuchasene namasuntswana othuthu oluphumayo (Mohs 5-7). Uvavanyo lwasentsimini lubonisa ukuba ii-nozzles zeSiC zihlala zigugile <5% emva kweeyure ezingama-20,000 zenkonzo, xa kuthelekiswa nokuguguleka kwe-30-40% kwii-nozzles ze-alumina kunye nokungaphumeleli ngokupheleleyo kweentsimbi ezigqunywe yi-polymer zingadlulanga iiyure ezingama-8,000.

4. Iimpawu zokuhamba komoya

Umphezulu ongamanzi we-SiC ebotshelelwe yi-reaction (i-contact angle >100°) yenza ukuba i-slurry dispersion ibe ngokuchanekileyo nge-CV values <5%. Umphezulu wayo ogudileyo kakhulu (Ra 0.2-0.4μm) unciphisa ukwehla koxinzelelo nge-15-20% xa kuthelekiswa nee-nozzles zesinyithi, ngelixa ugcina ii-discharge coefficients ezizinzileyo (±1%) ngexesha lokusebenza ixesha elide.

5. Ukugcinwa okulula

Ukungangeni kweekhemikhali zeSiC kuvumela iindlela zokucoca ngamandla eziquka:

- Ijethi yamanzi enoxinzelelo oluphezulu (ukuya kuthi ga kwi-250 bar)

- Ukucoca nge-ultrasonic ngezisombululo ze-alkaline

- Ukubulala iintsholongwane ngomphunga kwi-150°C

Ngaphandle komngcipheko wokonakala komphezulu oqhelekileyo kwimilomo yesinyithi egqunywe ngepolymer okanye egqunywe ngepeyinti.

6. Uqoqosho lweMijikelo yoBomi

Nangona iindleko zokuqala zee-nozzles ze-SiC ziphezulu nge-2-3× kune-stainless steel eqhelekileyo ye-316L, ubomi bazo benkonzo yeminyaka eyi-8-10 (xa kuthelekiswa neminyaka eyi-2-3 yeentsimbi) bunciphisa ukuphindaphinda kokutshintshwa nge-70%. Iindleko zobunini zizonke zibonisa ukonga kwe-40-60% kwiminyaka eli-10, kungekho xesha lokungasebenzi lokulungisa izinto ngaphakathi.

7. Ukuhambelana kokusingqongileyo

I-SiC ibonisa ukusebenza okungenakuthelekiswa nanto kwiimeko ezimandundu:

- Ukumelana netyuwa yokutshiza: 0% utshintsho lobunzima emva kovavanyo lwe-ASTM B117 lweeyure ezingama-5000

- Ukusebenza kwe-acid dew point: Iyamelana nomphunga we-H2SO4 we-160°C

- Ukumelana nobushushu: Iyasinda kwimijikelo yokucima i-1000°C →25°C

8. Iimpawu zokungakhuli

Isakhiwo se-atomic se-covalent se-SiC senza umphezulu ongeyo-reactive onezinga lokukala eliphantsi ngama-80% kunezinye iindlela zesinyithi. Izifundo ze-Crystallographic zibonisa ukuba i-calcite kunye ne-gypsum deposits zenza iibhondi ezibuthathaka (ukunamathela <1 MPa) kwi-SiC ngokuchasene ne->5 MPa kwisinyithi, nto leyo eyenza kube lula ukususa ngoomatshini.

Isiphelo soBugcisa

I-silicon carbide ceramic ivela njengokhetho olufanelekileyo lwezinto zokucoca i-FGD ngokuvavanya ukusebenza kwayo ngokupheleleyo:

- Ubomi benkonzo obude kangange-10× kunezinye iindlela zesinyithi

- Ukunciphisa ngama-92% kulondolozo olungacwangciswanga

- Uphuculo lwe-35% ekusebenzeni kakuhle kokususa i-SO2 ngokusebenzisa iipateni zokutshiza ezihambelanayo

- Ukuthobela ngokupheleleyo imigangatho yokukhutshwa komoya kwiCandelo 63 le-EPA 40 CFR

Ngeendlela zokuvelisa eziphucukileyo ezifana nokusinta okwenziwa liquid-phase kunye nokugquma kweCVD, ii-nozzles zeSiC zesizukulwana esilandelayo zifezekisa ukugqitywa komphezulu we-sub-micron kunye nejometri ezintsonkothileyo ezazingafumaneki ngaphambili kwi-ceramics. Olu tshintsho lobuchwepheshe lubeka i-silicon carbide njengezinto ezikhethwayo kwiinkqubo zokucoca igesi ye-flue zesizukulwana esilandelayo.

Ixesha lokuthumela: Matshi-20-2025