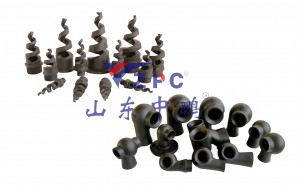

1. Kev Tiv Thaiv Kev Xeb

Cov nozzles FGDua haujlwm nyob rau hauv qhov chaw muaj zog heev uas muaj cov sulfur oxides, chlorides, thiab lwm yam tshuaj lom neeg hnyav. Silicon carbide (SiC) ceramic qhia tau tias muaj kev tiv thaiv corrosion zoo heev nrog tsawg dua 0.1% poob phaus hauv pH 1-14 cov tshuaj (ib qho kev sim ASTM C863). Piv rau cov hlau tsis xeb (PREN 18-25) thiab nickel alloys (PREN 30-40), SiC tswj kev ruaj khov ntawm cov qauv yam tsis muaj pitting lossis kev ntxhov siab corrosion tawg txawm tias nyob rau hauv cov kua qaub concentrated ntawm qhov kub siab.

2. Kev Ruaj Ntseg Kub Siab

Qhov kub ua haujlwm hauv cov tshuab desulfurization roj ntub feem ntau yog li ntawm 60-80 ° C nrog rau qhov siab tshaj 120 ° C. SiC ceramic khaws cia 85% ntawm nws lub zog hauv chav tsev ntawm 1400 ° C, ua tau zoo dua li alumina ceramics (poob 50% lub zog los ntawm 1000 ° C) thiab cov hlau uas tiv taus cua sov. Nws cov thermal conductivity (120 W / m · K) ua rau muaj kev kub hnyiab zoo, tiv thaiv kev ntxhov siab thermal.

3. Hnav Tsis Taus

Nrog Vickers hardness ntawm 28 GPa thiab fracture toughness ntawm 4.6 MPa·m¹/², SiC qhia tau tias muaj kev tiv thaiv kev yaig zoo dua tiv thaiv cov hmoov tshauv ya (Mohs 5-7). Kev sim hauv thaj teb qhia tau tias SiC nozzles tseem hnav tsawg dua 5% tom qab 20,000 teev kev pabcuam, piv rau 30-40% hnav hauv alumina nozzles thiab ua tsis tiav ntawm cov hlau polymer-coated hauv 8,000 teev.

4. Cov yam ntxwv ntawm kev ntws

Qhov chaw tsis ntub ntawm SiC uas tau sib txuas ua ke (lub kaum sab xis sib cuag >100°) ua rau muaj kev sib kis slurry meej nrog CV tus nqi <5%. Nws qhov chaw du heev (Ra 0.2-0.4μm) txo qhov siab poob los ntawm 15-20% piv rau cov hlau nozzles, thaum tswj cov coefficients tso tawm ruaj khov (± 1%) dhau sijhawm ua haujlwm ntev.

5. Kev Txij Nkawm Yooj Yim

SiC txoj kev tsis muaj tshuaj lom neeg tso cai rau cov txheej txheem ntxuav hnyav suav nrog:

- Lub tshuab dej siab heev (txog li 250 bar)

- Kev ntxuav ultrasonic nrog cov kua alkaline

- Siv lub tshuab ua kom huv ntawm 150 ° C

Tsis muaj kev pheej hmoo ntawm kev puas tsuaj ntawm qhov chaw uas feem ntau pom muaj nyob rau hauv cov hlau uas muaj polymer lossis coated.

6. Kev Lag Luam Txog Lub Neej

Txawm hais tias cov nqi pib rau SiC nozzles yog 2-3 × siab dua li tus qauv 316L stainless hlau, lawv lub neej ua haujlwm 8-10 xyoo (piv rau 2-3 xyoos rau cov hlau) txo qhov zaus hloov pauv los ntawm 70%. Tag nrho cov nqi muaj qhia tau tias txuag tau 40-60% dhau 10-xyoo, tsis muaj lub sijhawm tsis ua haujlwm rau kev kho hauv qhov chaw.

7. Kev Sib Haum Xeeb Ib puag ncig

SiC qhia txog kev ua tau zoo tsis muaj qhov sib piv hauv cov xwm txheej hnyav:

- Kev tiv thaiv ntsev tsuag: 0% kev hloov pauv loj tom qab 5000 teev ASTM B117 sim

- Kev ua haujlwm ntawm cov kua qaub dew point: Tiv taus 160 ° C H2SO4 vapors

- Kev tiv thaiv kev poob siab thermal: Muaj sia nyob 1000 ° C → 25 ° C quench cycles

8. Cov Khoom Tiv Thaiv Kev Ntshaw

Cov qauv atomic covalent ntawm SiC tsim ib qho chaw tsis muaj reactive nrog cov nqi scaling qis dua 80% piv rau lwm cov hlau. Cov kev tshawb fawb crystallographic qhia tau hais tias cov calcite thiab gypsum deposits tsim cov bonds tsis muaj zog (adhesion <1 MPa) ntawm SiC piv rau >5 MPa ntawm cov hlau, ua rau yooj yim dua mechanical tshem tawm.

Xaus Lus Txog Kev Txawj Ntse

Silicon carbide ceramic tshwm sim ua qhov kev xaiv khoom zoo tshaj plaws rau FGD nozzles los ntawm kev ntsuam xyuas kev ua tau zoo:

- 10 × lub neej ua haujlwm ntev dua li lwm cov hlau

- Txo tau 92% ntawm kev saib xyuas tsis tau npaj tseg

- Kev txhim kho 35% ntawm kev tshem tawm SO2 los ntawm cov qauv tsuag tsis tu ncua

- Ua raws li EPA 40 CFR Tshooj 63 cov qauv tso pa tawm tag nrho

Nrog rau kev nce qib ntawm cov txheej txheem tsim khoom xws li kev sib xyaw ua kua thiab CVD txheej, cov nozzles SiC tiam tom ntej tau ua tiav qhov tiav ntawm qhov chaw me dua thiab cov qauv nyuaj uas yav dhau los tsis tau ua tiav hauv cov khoom siv ceramics. Kev hloov pauv ntawm thev naus laus zis no tso silicon carbide ua cov khoom siv xaiv rau cov tshuab ntxuav roj flue tiam tom ntej.

Lub sijhawm tshaj tawm: Lub Peb Hlis-20-2025