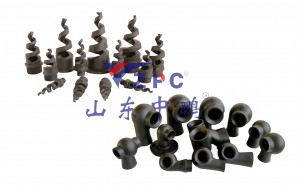

1. Juriyar Tsatsa

bututun FGDYana aiki a cikin yanayi mai yawan lalatawa wanda ke ɗauke da sinadarin sulfur oxides, chlorides, da sauran sinadarai masu ƙarfi. Yumburin silicon carbide (SiC) yana nuna juriya ga tsatsa tare da asarar taro ƙasa da kashi 0.1% a cikin mafita na pH 1-14 (bisa ga gwajin ASTM C863). Idan aka kwatanta da ƙarfe mai bakin ƙarfe (PREN 18-25) da ƙarfe nickel (PREN 30-40), SiC yana kiyaye daidaiton tsari ba tare da tsatsa ko damuwa ba ko da a cikin acid mai ƙarfi a yanayin zafi mai yawa.

2. Kwanciyar Hankali Mai Yawan Zafi

Yanayin zafi na aiki a cikin tsarin fitar da iskar gas mai danshi yawanci yana tsakanin 60-80°C tare da ƙwanƙwasawa sama da 120°C. SiC serami yana riƙe da kashi 85% na ƙarfin zafin ɗakinsa a 1400°C, yana yin aiki fiye da tukwanen alumina (yana rasa ƙarfi da kashi 50% da 1000°C) da ƙarfe masu jure zafi. Tsarin watsa zafi (120 W/m·K) yana ba da damar watsa zafi mai inganci, yana hana taruwar damuwa ta zafi.

3. Juriyar Sakawa

Tare da taurin Vickers na 28 GPa da kuma taurin karyewa na 4.6 MPa·m¹/², SiC yana nuna juriya mai kyau ga yashewa daga barbashin tokar kwari (Mohs 5-7). Gwaje-gwajen fili sun nuna cewa bututun SiC suna ci gaba da lalacewa <5% bayan sa'o'i 20,000 na aiki, idan aka kwatanta da lalacewar bututun alumina da kashi 30-40% da kuma gazawar gaba ɗaya na ƙarfe masu rufi da polymer cikin sa'o'i 8,000.

4. Halayen Guduwar Ruwa

Fuskar SiC mai ɗaurewa da amsawa (kusurwar hulɗa fiye da 100°) ba ta da jikewa sosai tare da ƙimar CV <5%. Fuskar sa mai santsi sosai (Ra 0.2-0.4μm) tana rage raguwar matsin lamba da kashi 15-20% idan aka kwatanta da bututun ƙarfe, yayin da take kiyaye daidaiton fitarwa (±1%) a tsawon lokaci.

5. Sauƙin Kulawa

Rashin daidaiton sinadarai na SiC yana ba da damar hanyoyin tsaftacewa masu ƙarfi waɗanda suka haɗa da:

- Jirgin ruwa mai ƙarfi (har zuwa mashaya 250)

- Tsaftacewa ta Ultrasonic tare da maganin alkaline

- Tsaftace tururi a zafin 150°C

Ba tare da haɗarin lalacewar saman da aka saba gani a cikin bututun ƙarfe masu rufi da polymer ko masu rufi ba.

6. Tattalin Arzikin Zamani

Duk da cewa farashin farko na bututun SiC ya fi na ƙarfe 316L na yau da kullun girma da 2-3×, tsawon lokacin sabis na shekaru 8-10 (idan aka kwatanta da shekaru 2-3 na ƙarfe) yana rage yawan maye gurbin da 70%. Jimlar kuɗin mallakar yana nuna tanadi 40-60% a cikin shekaru 10, tare da rashin lokacin aiki don gyaran da ke cikin gida.

7. Dacewa da Muhalli

SiC yana nuna aiki mara misaltuwa a cikin mawuyacin yanayi:

- Juriyar feshi mai gishiri: canjin taro 0% bayan gwajin ASTM B117 na awanni 5000

- Aikin wurin raɓar acid: Yana jure tururin H2SO4 160°C

- Juriyar girgizar zafi: Yana tsira daga zagayowar kashewa ta 1000°C→25°C

8. Halayen hana ƙima

Tsarin atomic na covalent na SiC yana ƙirƙirar saman da ba ya amsawa tare da ƙimar sikelin ƙasa da kashi 80% fiye da madadin ƙarfe. Nazarin kristal ya nuna cewa ma'ajiyar calcite da gypsum suna samar da haɗin gwiwa mai rauni (mannewa <1 MPa) akan SiC idan aka kwatanta da >5 MPa akan ƙarfe, wanda ke ba da damar cirewa cikin sauƙi ta injiniya.

Kammalawa ta Fasaha

Yumburin silicon carbide ya fito a matsayin mafi kyawun zaɓi na kayan don nozzles na FGD ta hanyar cikakken kimanta aiki:

- Tsawon rayuwar sabis na 10× fiye da madadin ƙarfe

- Rage kashi 92% na gyaran da ba a tsara ba

- Inganta kashi 35% a cikin ingancin cire SO2 ta hanyar tsarin feshi mai daidaito

- Cikakken bin ƙa'idodin hayaki na EPA 40 CFR Sashe na 63

Tare da ci gaba da dabarun kera kayayyaki kamar su sintering na ruwa da kuma rufe CVD, bututun SiC na zamani suna cimma kammalawar saman sub-micron da kuma yanayin ƙasa mai rikitarwa da ba a taɓa samu a cikin yumbu ba. Wannan juyin halittar fasaha yana sanya silicon carbide a matsayin kayan da aka fi so don tsarin tsaftace iskar gas na zamani.

Lokacin Saƙo: Maris-20-2025