Eminyakeni yamuva nje, ama-semiconductor e-silicon carbide compound athole ukunakwa okubanzi embonini. Kodwa-ke, njengezinto ezisebenza kahle kakhulu, i-silicon carbide iyingxenye encane nje yamadivayisi kagesi (ama-diode, amadivayisi kagesi). Ingasetshenziswa futhi njengezinto zokubhula, izinto zokusika, izinto zokwakha, izinto ezibonakalayo, abathwali be-catalyst, nokuningi. Namuhla, sethula kakhulu ama-ceramics e-silicon carbide, anezinzuzo zokuzinza kwamakhemikhali, ukumelana nokushisa okuphezulu, ukumelana nokuguguleka, ukumelana nokugqwala, ukuqhuba okuphezulu kokushisa, i-coefficient yokwanda kokushisa okuphansi, ubuningi obuphansi, kanye namandla aphezulu omshini. Asetshenziswa kabanzi emikhakheni efana nemishini yamakhemikhali, ukuvikelwa kwamandla nokwemvelo, ama-semiconductor, i-metallurgy, ukuzivikela kwezwe kanye nemboni yezempi.

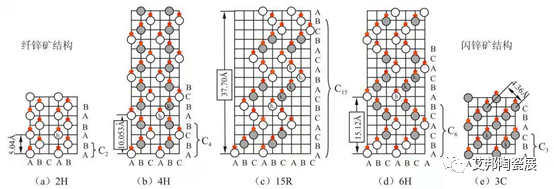

I-silicon carbide (i-SiC)iqukethe i-silicon ne-carbon, futhi iyinhlanganisela yesakhiwo ejwayelekile yezinhlobo eziningi, ikakhulukazi ehlanganisa izinhlobo ezimbili zekristalu: i-α – SiC (uhlobo oluzinzile olusezingeni eliphezulu) kanye ne-β – SiC (uhlobo oluzinzile olusezingeni eliphansi). Kunezinhlobo eziningi ezingaphezu kuka-200 sezizonke, phakathi kwazo i-3C SiC ye-β – SiC kanye ne-2H SiC, i-4H SiC, i-6H SiC, kanye ne-15R SiC ye-α – SiC ezimele.

Isakhiwo se-Figure SiC Multibody

Uma izinga lokushisa lingaphansi kuka-1600 ℃, i-SiC ikhona ngesimo se-β – SiC futhi ingalungiswa ngengxube elula ye-silicon ne-carbon cishe ku-1450 ℃. Uma izinga lokushisa lidlula ku-1600 ℃, i-β – SiC ishintsha kancane kancane ibe ama-polymorph ahlukahlukene e-α – SiC. I-4H SiC ikhiqizwa kalula cishe ku-2000 ℃; Womabili ama-polymorph angu-6H kanye no-15R adinga amazinga okushisa aphezulu ngaphezu kuka-2100 ℃ ukuze kube lula ukwakheka; i-6H SiC ingahlala izinzile ngisho noma amazinga okushisa edlula ku-2200 ℃, okwenza isetshenziswe kabanzi ezisetshenziswa ezimbonini.

I-silicon carbide emsulwa iyikristalu engenambala futhi esobala, kuyilapho i-silicon carbide yezimboni ingaba engenambala, ephuzi ngokuphaphathekile, eluhlaza okotshani, eluhlaza okotshani, eluhlaza okotshani, okwesibhakabhaka okukhanyayo, okwesibhakabhaka okumnyama, noma ngisho nomnyama, ngamazinga okukhanya anciphayo. Imboni ehluphayo ihlukanisa i-silicon carbide ngezinhlobo ezimbili ngokusekelwe kumbala: i-silicon carbide emnyama kanye ne-silicon carbide eluhlaza okotshani. I-silicon carbide engenambala kuya koluhlaza okotshani ihlukaniswa njenge-silicon carbide eluhlaza okotshani, kuyilapho i-silicon carbide eluhlaza okotshani kuya komnyama ihlukaniswa njenge-silicon carbide emnyama. I-silicon carbide emnyama kanye ne-silicon carbide eluhlaza kokubili kungamakristalu e-alpha SiC hexagonal, kanti i-silicon carbide micro powder eluhlaza ngokuvamile isetshenziswa njengezinto zokusetshenziswa ze-silicon carbide ceramics.

Ukusebenza kwe-Silicon Carbide Ceramics Okulungiselelwe Ngezinqubo Ezihlukene

Kodwa-ke, izitsha zobumba ze-silicon carbide zinobunzima bokuqina okuphansi kokuqhekeka kanye nokuqhekeka okuphezulu. Ngakho-ke, eminyakeni yamuva nje, izitsha zobumba ezihlanganisiwe ezisekelwe kuzitsha zobumba ze-silicon carbide, njengokuqinisa i-fiber (noma i-whisker), ukuqinisa ukuhlakazeka kwezinhlayiya ezingafani, kanye nezinto zokusebenza kwe-gradient, ziye zavela ngokulandelana, zithuthukisa ukuqina namandla ezinto ngazinye.

Njengezinto zokwakha ze-ceramic ezisezingeni eliphezulu ezisebenza kahle kakhulu, i-silicon carbide ceramics iye yasetshenziswa kakhulu kuma-oven asezingeni eliphezulu, i-metallurgy yensimbi, amakhemikhali kaphethroli, ama-electronics emishini, izindiza, amandla kanye nokuvikelwa kwemvelo, amandla enuzi, izimoto kanye neminye imikhakha.

Ngo-2022, usayizi wemakethe wezinto zobumba ze-silicon carbide eShayina kulindeleke ukuthi ufinyelele kuma-yuan ayizigidi eziyizinkulungwane ezingu-18.2. Njengoba kwanda amasimu okusetshenziswa kanye nezidingo zokukhula ezingezansi, kulinganiselwa ukuthi usayizi wemakethe wezinto zobumba ze-silicon carbide uzofinyelela kuma-yuan ayizigidi eziyizinkulungwane ezingu-29.6 ngo-2025.

Esikhathini esizayo, ngesilinganiso esikhulayo sokungena kwezimoto ezintsha zamandla, amandla, imboni, ukuxhumana kanye neminye imikhakha, kanye nezidingo eziqinile eziya ngokuya ziphezulu zezingxenye zemishini noma izingxenye ze-elekthronikhi ezinembile kakhulu, ezingagugi kakhulu, kanye nokuthembeka okuphezulu emikhakheni ehlukahlukene, kulindeleke ukuthi ubukhulu bemakethe yemikhiqizo ye-silicon carbide ceramic buqhubeke nokukhula, phakathi kwazo izimoto ezintsha zamandla kanye ne-photovoltaics kuyizindawo ezibalulekile zokuthuthukiswa.

Izitsha zobumba ze-silicon carbide zisetshenziswa kuma-oven e-ceramic ngenxa yezakhiwo zazo ezinhle kakhulu zomshini ezishisa kakhulu, ukumelana nomlilo, kanye nokumelana nokushaqeka kokushisa. Phakathi kwazo, ama-oven e-roller asetshenziswa kakhulu ekomiseni, ekushiseni, nasekuphatheni ukushisa kwezinto ze-electrode ze-lithium-ion battery positive, izinto ze-electrode ezingezinhle, kanye nama-electrolyte. Izinto ze-electrode ze-lithium battery positive kanye nezingezinhle zibalulekile ezimotweni ezintsha zamandla. Ifenisha ye-oven e-silicon carbide ceramic iyisici esibalulekile sama-oven, esingathuthukisa amandla okukhiqiza i-oven futhi sinciphise kakhulu ukusetshenziswa kwamandla.

Imikhiqizo ye-silicon carbide ceramic nayo isetshenziswa kabanzi ezingxenyeni ezahlukene zezimoto. Ngaphezu kwalokho, amadivayisi e-SiC asetshenziswa kakhulu kuma-PCU (amayunithi okulawula amandla, njenge-DC/DC esebhodini) kanye nama-OBC (amayunithi okushaja) ezimoto ezintsha zamandla. Amadivayisi e-SiC anganciphisa isisindo kanye nomthamo wemishini ye-PCU, anciphise ukulahlekelwa yi-switch, futhi athuthukise izinga lokushisa lokusebenza kanye nokusebenza kahle kwesistimu yamadivayisi; Kungenzeka futhi ukwandisa izinga lamandla eyunithi, ukwenza lula isakhiwo sesekethe, ukuthuthukisa ubuningi bamandla, kanye nokwandisa isivinini sokushaja ngesikhathi sokushaja kwe-OBC. Njengamanje, izinkampani eziningi zezimoto emhlabeni wonke zisebenzise i-silicon carbide kumamodeli amaningi, futhi ukwamukelwa okukhulu kwe-silicon carbide sekuyinto evamile.

Lapho kusetshenziswa i-silicon carbide ceramics njengezinto ezibalulekile zokuthwala enqubweni yokukhiqizwa kwamaseli e-photovoltaic, imikhiqizo evelayo efana nezisekelo zesikebhe, amabhokisi esikebhe, kanye nokufakwa kwamapayipi inokuqina okuhle kokushisa, ayiguquki uma isetshenziswa emazingeni okushisa aphezulu, futhi ayikhiqizi ukungcola okuyingozi. Ingathatha indawo yezisekelo zesikebhe ze-quartz ezisetshenziswa kakhulu, amabhokisi esikebhe, kanye nokufakwa kwamapayipi, futhi inezinzuzo ezinkulu zezindleko.

Ngaphezu kwalokho, amathuba emakethe amadivayisi kagesi e-photovoltaic silicon carbide abanzi. Izinto ze-SiC zinezici eziphansi zokumelana, ukushaja kwesango, kanye nokushaja okubuyiselwe emuva. Ukusebenzisa i-SiC Mosfet noma i-SiC Mosfet kuhlanganiswe nama-inverter e-SiC SBD photovoltaic kungandisa ukusebenza kahle kokuguqulwa kusuka ku-96% kuya ngaphezu kuka-99%, kunciphise ukulahlekelwa kwamandla ngaphezu kuka-50%, futhi kwandise impilo yomjikelezo wemishini ngezikhathi ezingu-50.

Ukwenziwa kwe-silicon carbide ceramics kungalandelelwa emuva ngawo-1890, lapho i-silicon carbide yayisetshenziswa kakhulu ezintweni zokugaya ngomshini kanye nezinto eziphikisayo. Ngokuthuthuka kobuchwepheshe bokukhiqiza, imikhiqizo ye-SiC yobuchwepheshe obuphezulu iye yathuthukiswa kabanzi, futhi amazwe emhlabeni wonke agxila kakhulu ekuthuthukisweni kwezimboni ze-ceramics ezithuthukisiwe. Awenelisekile ngokulungiswa kwe-silicon carbide ceramics yendabuko. Amabhizinisi akhiqiza i-ceramics yobuchwepheshe obuphezulu athuthuka ngokushesha, ikakhulukazi emazweni athuthukile lapho lesi simo sibaluleke kakhulu. Abakhiqizi bangaphandle bahlanganisa kakhulu iSaint Gobain, 3M, CeramTec, IBIDEN, Schunk, Narita Group, Toto Corporation, CoorsTek, Kyocera, Aszac, Japan Jingke Ceramics Co., Ltd., Japan Special Ceramics Co., Ltd., IPS Ceramics, njll.

Ukuthuthukiswa kwe-silicon carbide eShayina kwase kwephuzile uma kuqhathaniswa namazwe athuthukile njengeYurophu neMelika. Selokhu kwakhiwa isithando sokuqala sezimboni sokukhiqiza i-SiC eFirst Grinding Wheel Factory ngoJuni 1951, iShayina yaqala ukukhiqiza i-silicon carbide. Abakhiqizi basekhaya be-silicon carbide ceramics bagxile kakhulu eWeifang City, eSifundazweni saseShandong. Ngokusho kochwepheshe, lokhu kungenxa yokuthi amabhizinisi endawo okumbiwa kwamalahle abhekene nokuqothuka futhi afuna uguquko. Ezinye izinkampani zethule imishini efanele evela eJalimane ukuqala ukucwaninga nokukhiqiza i-silicon carbide.I-ZPC ingenye yezinkampani ezinkulu kakhulu zokukhiqiza i-silicon carbide ephefumulayo.

Isikhathi sokuthunyelwe: Novemba-09-2024