Lilemong tsa morao tjena, li-semiconductor tsa motsoako oa silicon carbide li fumane tlhokomelo e pharaletseng indastering. Leha ho le joalo, e le thepa e sebetsang hantle, silicon carbide ke karolo e nyane feela ea lisebelisoa tsa elektroniki (diode, lisebelisoa tsa motlakase). E ka boela ea sebelisoa e le li-abrasives, lisebelisoa tsa ho seha, thepa ea sebopeho, thepa ea optical, li-catalyst carriers, le tse ling. Kajeno, re hlahisa haholo-holo li-ceramic tsa silicon carbide, tse nang le melemo ea botsitso ba lik'hemik'hale, ho hanyetsa mocheso o phahameng, ho hanyetsa ho tsofala, ho hanyetsa ho bola, ho khanna mocheso o phahameng, coefficient e tlase ea katoloso ea mocheso, letsoalo le tlase, le matla a phahameng a mechini. Li sebelisoa haholo masimong a kang mechine ea lik'hemik'hale, matla le tšireletso ea tikoloho, li-semiconductor, tšepe, tšireletso ea naha le indasteri ea sesole.

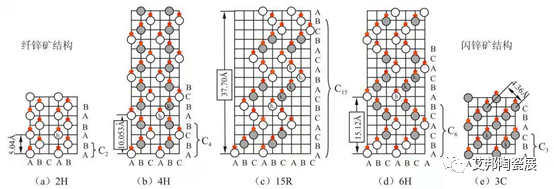

Carbide ea silicon (SiC)e na le silicon le khabone, 'me ke motsoako o tloaelehileng oa sebopeho sa mefuta e mengata, haholo-holo o kenyeletsang mefuta e 'meli ea kristale: α – SiC (mofuta o tsitsitseng oa mocheso o phahameng) le β – SiC (mofuta o tsitsitseng oa mocheso o tlase). Ho na le mefuta e mengata e fetang 200 ka kakaretso, eo har'a eona 3C SiC ea β – SiC le 2H SiC, 4H SiC, 6H SiC, le 15R SiC ea α – SiC li emelang.

Sebopeho sa Setšoantšo sa SiC Multibody

Ha mocheso o le ka tlase ho 1600 ℃, SiC e teng ka sebopeho sa β – SiC mme e ka lokiswa ho tswa motswakong o bonolo wa silicon le khabone hoo e ka bang 1450 ℃. Ha mocheso o feta 1600 ℃, β – SiC e fetoha butle-butle ho ba di-polymorph tse fapaneng tsa α – SiC. 4H SiC e hlahiswa habonolo hoo e ka bang 2000 ℃; Di-polymorph tsa 6H le 15R ka bobedi di hloka mocheso o phahameng o fetang 2100 ℃ bakeng sa ho thehwa ha bonolo; 6H SiC e ka dula e tsitsitse haholo esita le mochesong o fetang 2200 ℃, e leng se etsang hore e sebediswe haholo dibakeng tsa indasteri.

Carbide e hloekileng ea silicon ke kristale e se nang 'mala le e bonaletsang, ha carbide ea silicon ea indasteri e ka ba e se nang 'mala, e mosehla o moputsoa, e tala e bobebe, e tala e lefifi, e putsoa e bobebe, e putsoa e lefifi, kapa esita le e ntšo, ka maemo a fokotsehang a pepeneneng. Indasteri ea khorofo e arola carbide ea silicon ka mefuta e 'meli ho latela' mala: carbide e ntšo ea silicon le carbide e tala ea silicon. Carbide ea silicon e se nang 'mala ho isa ho e tala e arotsoe e le carbide e tala ea silicon, ha carbide ea silicon e putsoa e bobebe ho isa ho e ntšo e arotsoe e le carbide e ntšo ea silicon. Carbide e ntšo ea silicon le carbide e tala ea silicon ka bobeli ke likristale tsa alpha SiC tse nang le mahlakore a tšeletseng, 'me phofo e nyane ea silicon carbide e tala hangata e sebelisoa e le thepa e tala bakeng sa li-ceramics tsa silicon carbide.

Tshebetso ea Li-ceramic tsa Silicon Carbide tse Lokisitsoeng ke Mekhoa e Fapaneng

Leha ho le jwalo, diserame tsa silicon carbide di na le bothata ba ho ba thata ho robeha le ho ba bosawana bo phahameng. Ka hona, dilemong tsa morao tjena, diserame tse kopaneng tse thehilweng hodima diserame tsa silicon carbide, tse kang matlafatso ya faeba (kapa whisker), matlafatso ya ho hasana ha dikarolwana tse fapaneng, le thepa e sebetsang ya gradient, di hlahile ka ho latellana, di ntlafatsa thatafalo le matla a thepa ka nngwe.

Jwalo ka thepa ya ceramic e sebetsang hantle haholo, di-ceramic tsa silicon carbide di sebedisitsoe haholo diontong tsa mocheso o phahameng, tshepe ya tshepe, dikhemikhale tsa peterole, di-elektroniki tsa mechini, difofane, matla le tshireletso ya tikoloho, matla a nyutlelie, dikoloi le masimo a mang.

Ka 2022, boholo ba 'maraka oa li-ceramic tsa sebopeho sa silicon carbide Chaena bo lebelletsoe ho fihla ho li-yuan tse libilione tse 18.2. Ka katoloso e eketsehileng ea masimo a ts'ebeliso le litlhoko tsa kholo e theohelang, ho hakanngoa hore boholo ba 'maraka oa li-ceramic tsa sebopeho sa silicon carbide bo tla fihla ho li-yuan tse libilione tse 29.6 ka 2025.

Nakong e tlang, ka sekhahla se ntseng se eketseha sa ho kenella ha likoloi tse ncha tsa eneji, matla, indasteri, puisano le masimo a mang, hammoho le litlhoko tse thata tse ntseng li eketseha tsa likarolo tsa mechini kapa likarolo tsa elektroniki tse nepahetseng haholo, tse hanyetsang ho tsofala haholo, le tse tšepahalang haholo masimong a fapaneng, boholo ba 'maraka oa lihlahisoa tsa ceramic tsa silicon carbide bo lebelletsoe ho tsoela pele ho hola, tseo har'a tsona likoloi tse ncha tsa eneji le li-photovoltaics e leng libaka tsa bohlokoa tsa nts'etsopele.

Diserami tsa silicon carbide di sebediswa diontong tsa ceramic ka lebaka la thepa ya tsona e ntle ya mechine e nang le mocheso o phahameng, ho hanyetsa mollo, le ho hanyetsa ho thothomela ha mocheso. Har'a tsona, diontong tsa roller di sebediswa haholo bakeng sa ho omisa, ho tjhesa le ho phekola mocheso wa thepa ya electrode ya lithium-ion, thepa ya electrode e mpe, le di-electrolyte. Thepa ya electrode e ntle le e mpe ya betri ya lithium ke ya bohlokwa bakeng sa dikoloi tse ntjha tsa eneji. Thepa ya ka tlung ya silicon carbide ke karolo ya bohlokwa ya diontong, e ka ntlafatsang bokgoni ba tlhahiso ya ontong le ho fokotsa tshebediso ya matla haholo.

Lihlahisoa tsa ceramic tsa silicon carbide le tsona li sebelisoa haholo likarolong tse fapaneng tsa likoloi. Ho phaella moo, lisebelisoa tsa SiC li sebelisoa haholo ho PCUs (li-unit tsa taolo ea matla, joalo ka DC/DC e ka har'a sekepe) le OBCs (li-unit tsa ho tjhaja) tsa likoloi tse ncha tsa matla. Lisebelisoa tsa SiC li ka fokotsa boima le bophahamo ba lisebelisoa tsa PCU, tsa fokotsa tahlehelo ea switch, le ho ntlafatsa mocheso oa ts'ebetso le katleho ea sistimi ea lisebelisoa; Hoa khoneha hape ho eketsa boemo ba matla a yuniti, ho nolofatsa sebopeho sa potoloho, ho ntlafatsa bongata ba matla, le ho eketsa lebelo la ho tjhaja nakong ea ho tjhaja OBC. Hona joale, lik'hamphani tse ngata tsa likoloi lefatšeng ka bophara li sebelisitse silicon carbide mehlala e mengata, 'me ho amoheloa ka bongata ha silicon carbide e se e le mokhoa.

Ha diseramiki tsa silicon carbide di sebediswa e le thepa ya bohlokwa ya ho jara tshebetsong ya tlhahiso ya disele tsa photovoltaic, dihlahiswa tse hlahang jwalo ka ditšehetso tsa sekepe, mabokose a sekepe, le di-fitting tsa diphaephe di na le botsitso bo botle ba mocheso, ha di senyehe ha di sebediswa dithempereichara tse phahameng, mme ha di hlahise ditshila tse kotsi. Di ka nkela ditšehetso tsa sekepe sa quartz tse sebediswang hangata sebaka, mabokose a sekepe, le di-fitting tsa diphaephe sebaka, mme di na le melemo e meholo ya ditjeo.

Ho phaella moo, menyetla ea 'maraka ea lisebelisoa tsa motlakase tsa silicon carbide ea photovoltaic e pharaletse. Lisebelisoa tsa SiC li na le litšobotsi tse tlase tsa ho hanyetsa, ho tjhaja ha heke, le ho khutlisa matla. Ho sebelisa SiC Mosfet kapa SiC Mosfet hammoho le li-inverter tsa SiC SBD photovoltaic ho ka eketsa bokhoni ba phetoho ho tloha ho 96% ho ea ho feta 99%, ho fokotsa tahlehelo ea matla ka ho feta 50%, le ho eketsa bophelo ba potoloho ea lisebelisoa ka makhetlo a 50.

Ho kopanngoa ha li-ceramic tsa silicon carbide ho ka lateloa morao ho fihlela lilemong tsa bo-1890, ha silicon carbide e ne e sebelisoa haholo-holo bakeng sa thepa ea ho sila ea mechine le thepa e hanyetsang. Ka nts'etsopele ea theknoloji ea tlhahiso, lihlahisoa tsa SiC tsa theknoloji e phahameng li ntlafalitsoe haholo, 'me linaha lefatšeng ka bophara li ela hloko haholoanyane ntlafatso ea li-ceramic tse tsoetseng pele. Ha li sa khotsofala ke ho lokisoa ha li-ceramic tsa silicon carbide tsa setso. Likhamphani tse hlahisang li-ceramic tsa theknoloji e phahameng li ntse li hola ka potlako, haholo-holo linaheng tse tsoetseng pele moo ketsahalo ena e leng ea bohlokoa haholoanyane. Bahlahisi ba kantle ho naha ba kenyelletsa haholo-holo Saint Gobain, 3M, CeramTec, IBIDEN, Schunk, Narita Group, Toto Corporation, CoorsTek, Kyocera, Aszac, Japan Jingke Ceramics Co., Ltd., Japan Special Ceramics Co., Ltd., IPS Ceramics, jj.

Nts'etsopele ea carbide ea silicon Chaena e ile ea lieha haholo ha e bapisoa le linaha tse tsoetseng pele tse kang Europe le Amerika. Ho tloha ha sebōpi sa pele sa indasteri sa tlhahiso ea SiC se hahuoa Fekthering ea Pele ea Mabili a ho Sila ka Phuptjane 1951, Chaena e ile ea qala ho hlahisa carbide ea silicon. Bahlahisi ba malapeng ba li-ceramics tsa silicon carbide ba shebane haholo le Motse oa Weifang, Profinseng ea Shandong. Ho ea ka litsebi, sena se bakoa ke hore likhoebo tsa merafo ea mashala tsa lehae li tobane le ho putlama 'me li batla phetoho. Likhamphani tse ling li hlahisitse lisebelisoa tse amehang ho tsoa Jeremane ho qala ho etsa lipatlisiso le ho hlahisa carbide ea silicon.ZPC ke e 'ngoe ea bahlahisi ba bangata ba silicon carbide e nang le karabelo e matla.

Nako ea poso: Pulungoana-09-2024