A cikin 'yan shekarun nan, semiconductors na silicon carbide compound sun sami kulawa sosai a masana'antar. Duk da haka, a matsayin kayan aiki mai inganci, silicon carbide ƙaramin ɓangare ne kawai na na'urorin lantarki (diodes, na'urorin wutar lantarki). Haka kuma ana iya amfani da shi azaman gogewa, kayan yankewa, kayan gini, kayan gani, masu ɗaukar abubuwan kara kuzari, da ƙari. A yau, galibi muna gabatar da yumbu na silicon carbide, waɗanda ke da fa'idodin kwanciyar hankali na sinadarai, juriyar zafi mai yawa, juriyar lalacewa, juriyar tsatsa, juriyar zafi mai yawa, ƙarancin haɓakar zafi, ƙarancin yawa, da ƙarfin injina mai yawa. Ana amfani da su sosai a fannoni kamar injunan sinadarai, makamashi da kariyar muhalli, semiconductors, ƙarfe, tsaron ƙasa da masana'antar soja.

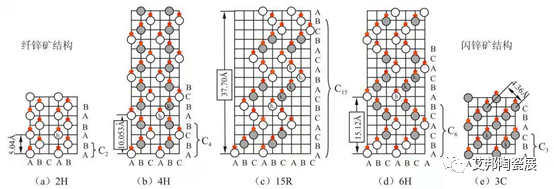

Silikon carbide (SiC)ya ƙunshi silicon da carbon, kuma wani sinadari ne na tsari iri-iri, wanda ya haɗa da nau'ikan lu'ulu'u guda biyu: α - SiC (nau'in kwanciyar hankali mai zafi) da β - SiC (nau'in kwanciyar hankali mai ƙarancin zafi). Akwai nau'ikan yanayi daban-daban sama da 200, daga cikinsu akwai 3C SiC na β - SiC da 2H SiC, 4H SiC, 6H SiC, da 15R SiC na α - SiC.

Tsarin SiC na Jiki da Yawa

Idan zafin ya ƙasa da 1600 ℃, SiC yana wanzuwa a cikin nau'in β – SiC kuma ana iya shirya shi daga cakuda mai sauƙi na silicon da carbon a kusan 1450 ℃. Lokacin da zafin ya wuce 1600 ℃, β – SiC yana canzawa a hankali zuwa nau'ikan polymorphs daban-daban na α – SiC. Ana samar da 4H SiC cikin sauƙi a kusan 2000 ℃; Duk polymorphs na 6H da 15R suna buƙatar yanayin zafi mai yawa sama da 2100 ℃ don sauƙin samuwa; 6H SiC na iya kasancewa mai karko sosai ko da a yanayin zafi ya wuce 2200 ℃, wanda hakan ke sa a yi amfani da shi sosai a aikace-aikacen masana'antu.

Tsarkakken silicon carbide lu'ulu'u ne mara launi da haske, yayin da silicon carbide na masana'antu na iya zama mara launi, rawaya mai haske, kore mai haske, kore mai duhu, shuɗi mai haske, shuɗi mai duhu, ko ma baƙi, tare da raguwar matakan haske. Masana'antar abrasion ta rarraba silicon carbide zuwa nau'i biyu dangane da launi: baƙar silicon carbide da kore silicon carbide. Ba tare da launi zuwa kore mai duhu ba ana rarraba silicon carbide mai duhu a matsayin kore silicon carbide, yayin da shuɗi mai haske zuwa baƙi silicon carbide ana rarraba shi azaman baƙar silicon carbide. Baƙar silicon carbide da kore silicon carbide duka lu'ulu'u ne masu siffar alpha SiC, kuma galibi ana amfani da foda mai siffar silicon carbide mai launin kore azaman kayan aiki don yumburan silicon carbide.

Aikin Ceramics na Silicon Carbide da aka Shirya ta hanyoyi daban-daban

Duk da haka, tukwanen silicon carbide suna da rashin ƙarfi na ƙarancin tauri da kuma ƙarfin karyewa. Saboda haka, a cikin 'yan shekarun nan, tukwanen silicon carbide masu haɗaka waɗanda aka gina bisa ga tukwanen silicon carbide, kamar ƙarfafa zare (ko wisker), ƙarfafa watsa barbashi iri-iri, da kayan aiki masu sauƙin fahimta, sun bayyana a jere, suna inganta tauri da ƙarfin kayan aiki daban-daban.

A matsayin wani abu mai ƙarfi na yumbu mai ƙarfi, ana ƙara amfani da yumbu na silicon carbide a cikin murhunan zafi mai zafi, masana'antar ƙarfe, sinadarai na petrochemicals, na'urorin lantarki na injiniya, sararin samaniya, makamashi da kariyar muhalli, makamashin nukiliya, motoci da sauran fannoni.

A shekarar 2022, ana sa ran girman kasuwar yumbun silicon carbide a kasar Sin zai kai yuan biliyan 18.2. Tare da fadada fannonin amfani da shi da kuma bukatu na ci gaba, an kiyasta cewa girman kasuwa na yumbun silicon carbide zai kai yuan biliyan 29.6 nan da shekarar 2025.

A nan gaba, tare da karuwar yawan shigar sabbin motocin makamashi, makamashi, masana'antu, sadarwa da sauran fannoni, da kuma tsauraran buƙatu don ingantattun kayan aikin injiniya ko kayan lantarki a fannoni daban-daban, ana sa ran girman kasuwa na kayayyakin yumbu na silicon carbide zai ci gaba da faɗaɗa, daga cikinsu sabbin motocin makamashi da kuma na'urorin daukar hoto muhimmin fannoni ne na ci gaba.

Ana amfani da yumburan silicon carbide a cikin murhun yumbu saboda kyawawan halayen injina masu zafi, juriyar wuta, da juriyar girgizar zafi. Daga cikinsu, murhun rola galibi ana amfani da su don busarwa, sintering, da maganin zafi na kayan lantarki masu kyau na batirin lithium-ion, kayan lantarki masu kyau, da electrolytes. Kayan lantarki masu kyau da mara kyau na batirin lithium suna da mahimmanci ga sabbin motocin makamashi. Kayan daki na murhun yumbu na silicon carbide muhimmin sashi ne na murhun, wanda zai iya inganta ƙarfin samar da murhun da kuma rage yawan amfani da makamashi sosai.

Ana kuma amfani da kayayyakin yumbu na silicon carbide sosai a cikin sassa daban-daban na motoci. Bugu da ƙari, ana amfani da na'urorin SiC galibi a cikin PCUs (na'urorin sarrafa wutar lantarki, kamar DC/DC a kan jirgin) da OBCs (na'urorin caji) na sabbin motocin makamashi. Na'urorin SiC na iya rage nauyi da girman kayan aikin PCU, rage asarar makulli, da inganta yanayin zafi da ingancin tsarin na'urori; Hakanan yana yiwuwa a ƙara matakin wutar lantarki na na'urar, sauƙaƙe tsarin da'ira, inganta yawan wutar lantarki, da ƙara saurin caji yayin caji na OBC. A halin yanzu, kamfanonin motoci da yawa a duniya sun yi amfani da silicon carbide a cikin samfura da yawa, kuma ɗaukar babban silicon carbide ya zama abin birgewa.

Idan ana amfani da yumburan silicon carbide a matsayin kayan ɗaukar kaya masu mahimmanci a cikin tsarin samar da ƙwayoyin photovoltaic, samfuran da aka samar kamar tallafin jirgin ruwa, akwatunan jirgin ruwa, da kayan haɗin bututu suna da kyakkyawan kwanciyar hankali na zafi, ba sa lalacewa lokacin amfani da su a yanayin zafi mai yawa, kuma ba sa haifar da gurɓatattun abubuwa masu cutarwa. Suna iya maye gurbin tallafin jirgin ruwa na quartz da aka saba amfani da shi, akwatunan jirgin ruwa, da kayan haɗin bututu, kuma suna da fa'idodi masu yawa na farashi.

Bugu da ƙari, hasashen kasuwa na na'urorin wutar lantarki na silicon carbide na photovoltaic yana da faɗi. Kayan SiC suna da ƙarancin juriya, cajin ƙofa, da halayen cajin dawowar baya. Amfani da SiC Mosfet ko SiC Mosfet tare da inverters na photovoltaic na SiC SBD na iya ƙara ingancin juyawa daga 96% zuwa sama da 99%, rage asarar makamashi da fiye da 50%, da kuma ƙara tsawon rayuwar zagayowar kayan aiki da sau 50.

Ana iya gano yadda ake haɗa yumburan silicon carbide tun daga shekarun 1890, lokacin da ake amfani da silicon carbide galibi don kayan niƙa na injiniya da kayan da ba sa jurewa. Tare da haɓaka fasahar samarwa, an haɓaka samfuran SiC masu fasaha sosai, kuma ƙasashe a faɗin duniya suna mai da hankali sosai ga ci gaban masana'antu na yumbu na zamani. Ba su gamsu da shirya yumburan silicon carbide na gargajiya ba. Kamfanonin da ke samar da yumbu na fasaha suna haɓaka cikin sauri, musamman a ƙasashen da suka ci gaba inda wannan lamari ya fi muhimmanci. Masana'antun ƙasashen waje galibi sun haɗa da Saint Gobain, 3M, CeramTec, IBIDEN, Schunk, Narita Group, Toto Corporation, CoorsTek, Kyocera, Aszac, Japan Jingke Ceramics Co., Ltd., Japan Special Ceramics Co., Ltd., IPS Ceramics, da sauransu.

Ci gaban silicon carbide a China ya kasance a makare idan aka kwatanta da ƙasashe masu tasowa kamar Turai da Amurka. Tun lokacin da aka gina tanda ta farko ta masana'antu don kera SiC a Masana'antar Niƙa Tayar Farko a watan Yunin 1951, China ta fara samar da silicon carbide. Masu kera yumbu na silicon carbide na cikin gida galibi suna cikin birnin Weifang, lardin Shandong. A cewar ƙwararru, wannan ya faru ne saboda kamfanonin haƙar kwal na gida suna fuskantar fatarar kuɗi kuma suna neman sauyi. Wasu kamfanoni sun gabatar da kayan aiki masu dacewa daga Jamus don fara bincike da samar da silicon carbide.ZPC yana ɗaya daga cikin manyan masana'antun carbide na silicon sintered.

Lokacin Saƙo: Nuwamba-09-2024