Kwiminyaka yakutshanje, ii-semiconductors ze-silicon carbide compound ziye zafumana ingqalelo enkulu kushishino. Nangona kunjalo, njengezinto ezisebenza kakuhle, i-silicon carbide yinxalenye encinci yezixhobo ze-elektroniki (ii-diode, izixhobo zamandla). Ingasetyenziswa njengezinto zokubrasive, izinto zokusika, izinto zokwakha, izinto ezibonakalayo, ii-catalyst carriers, nokunye. Namhlanje, sazisa ikakhulu ii-ceramics ze-silicon carbide, ezineenzuzo zokuzinza kweekhemikhali, ukumelana nobushushu obuphezulu, ukumelana nokuguguleka, ukumelana nokugqwala, ukuqhuba okuphezulu kobushushu, i-low thermal expansion coefficient, i-low density, kunye namandla aphezulu oomatshini. Zisetyenziswa kakhulu kwiindawo ezifana noomatshini beekhemikhali, amandla kunye nokukhuselwa kwendalo, ii-semiconductors, i-metallurgy, ukhuselo lwesizwe kunye noshishino lomkhosi.

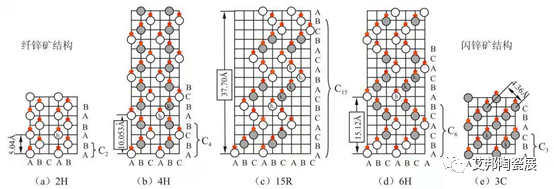

I-silicon carbide (i-SiC)ine-silicon kunye ne-carbon, kwaye yi-compound eqhelekileyo yesakhiwo seentlobo ezininzi, ikakhulu equka iintlobo ezimbini zekristale: α – SiC (uhlobo oluzinzileyo lobushushu obuphezulu) kunye ne-β – SiC (uhlobo oluzinzileyo lobushushu obuphantsi). Kukho iintlobo ezininzi ezingaphezu kwama-200 xa zizonke, phakathi kwazo i-3C SiC ye-β – SiC kunye ne-2H SiC, 4H SiC, 6H SiC, kunye ne-15R SiC ye-α – SiC zimela.

Ulwakhiwo lweSiC Multibody

Xa ubushushu bungaphantsi kwe-1600 ℃, i-SiC ikhona ngohlobo lwe-β-SiC kwaye ingalungiswa ngomxube olula we-silicon kunye ne-carbon malunga ne-1450 ℃. Xa ubushushu budlula i-1600 ℃, i-β-SiC itshintsha kancinci ibe zii-polymorphs ezahlukeneyo ze-α-SiC. I-4H SiC iveliswa lula malunga ne-2000 ℃; Zombini ii-polymorphs ze-6H kunye ne-15R zifuna ubushushu obuphezulu obungaphezulu kwe-2100 ℃ ukuze kube lula ukuyilwa; i-6H SiC inokuhlala izinzile nokuba kubushushu obungaphezulu kwe-2200 ℃, nto leyo eyenza ukuba isetyenziswe kakhulu kwizicelo zoshishino.

I-silicon carbide ecocekileyo yikristale engenambala necacileyo, ngelixa i-silicon carbide yemizi-mveliso inokuba nombala, ibe mthubi okhanyayo, ibe luhlaza okotshani, ibe luhlaza okotshani, ibe luhlaza okotshani, ibe luhlaza okotshani, ibe luhlaza okotshani, okanye ibe mnyama, kunye namanqanaba okucaca anciphayo. Ishishini elirhabaxa lihlela i-silicon carbide kwiindidi ezimbini ngokusekelwe kumbala: i-silicon carbide emnyama kunye ne-silicon carbide eluhlaza okotshani. I-silicon carbide engenambala ukuya kuluhlaza okotshani ihlelwa njenge-silicon carbide eluhlaza okotshani, ngelixa i-silicon carbide ekhanyayo ukuya kumnyama ihlelwa njenge-silicon carbide emnyama. I-silicon carbide emnyama kunye ne-silicon carbide eluhlaza zombini ziikristale ze-alpha SiC hexagonal, kwaye i-silicon carbide micro powder eluhlaza isetyenziswa ngokubanzi njengezinto eziluhlaza ze-silicon carbide ceramics.

Ukusebenza kweSilicon Carbide Ceramics elungiselelwe ziinkqubo ezahlukeneyo

Nangona kunjalo, ii-silicon carbide ceramics zineengxaki zokuqina okuphantsi kokuqhekeka kunye nokuqhekeka okuphezulu. Ke ngoko, kwiminyaka yakutshanje, ii-composite ceramics ezisekelwe kwi-silicon carbide ceramics, ezifana ne-fiber (okanye i-whisker) reinforcement, i-heterogeneous particle dispersion strength, kunye nezixhobo ezisebenzayo ze-gradient, ziye zavela ngokulandelelana, ziphucula ukuqina kunye namandla ezixhobo ngazinye.

Njengesixhobo se-ceramic esisebenza kakuhle kakhulu esinobushushu obuphezulu, ii-silicon carbide ceramics ziye zasetyenziswa ngakumbi kwii-ovens ezisebenzisa ubushushu obuphezulu, i-metallurgy yentsimbi, ii-petrochemicals, ii-electronics zoomatshini, i-aerospace, amandla kunye nokhuseleko lokusingqongileyo, amandla enyukliya, iimoto kunye nezinye iindawo.

Ngowama-2022, ubungakanani bemarike yeeseramikhi zesakhiwo sesilicon carbide eTshayina kulindeleke ukuba bufikelele kwi-18.2 yeebhiliyoni zeeyuan. Njengoko kwanda ngakumbi amasimi okusetyenziswa kunye neemfuno zokukhula okusezantsi, kuqikelelwa ukuba ubungakanani bemarike yeeseramikhi zesakhiwo sesilicon carbide buza kufikelela kwi-29.6 yeebhiliyoni zeeyuan ngo-2025.

Kwixesha elizayo, ngenxa yokwanda kwesantya sokungena kwezithuthi ezintsha zamandla, amandla, ishishini, unxibelelwano kunye nezinye iinkalo, kunye neemfuno ezingqongqo ngakumbi zezixhobo zoomatshini okanye izixhobo ze-elektroniki ezichanekileyo kakhulu, ezinganyangekiyo kakhulu, kunye nokuthembeka okuphezulu kwiindawo ezahlukeneyo, ubungakanani bemarike yeemveliso ze-silicon carbide ceramic kulindeleke ukuba buqhubeke nokukhula, phakathi kwazo izithuthi ezintsha zamandla kunye ne-photovoltaics ziindawo ezibalulekileyo zophuhliso.

Iiceramics ze-silicon carbide zisetyenziswa kwii-oven ze-ceramic ngenxa yeempawu zazo ezintle kakhulu zoomatshini ezishushu kakhulu, ukumelana nomlilo, kunye nokumelana nobushushu. Phakathi kwazo, ii-oven ze-roller zisetyenziselwa ukomisa, ukuthulula, kunye nonyango lobushushu bezinto ze-electrode ze-lithium-ion battery positive, izinto ze-electrode ezingalunganga, kunye nee-electrolytes. Izinto ze-electrode ze-lithium battery positive kunye ne-negative ziyimfuneko kwizithuthi zamandla amatsha. Ifenitshala ye-oven ye-silicon carbide ceramic yinxalenye ebalulekileyo yee-oven, enokuphucula amandla okuvelisa i-oven kwaye inciphise kakhulu ukusetyenziswa kwamandla.

Iimveliso ze-silicon carbide ceramic zikwasetyenziswa kakhulu kwiindawo ezahlukeneyo zeemoto. Ukongeza, izixhobo zeSiC zisetyenziswa kakhulu kwi-PCUs (iiyunithi zokulawula amandla, ezifana ne-DC/DC esebhodini) kunye nee-OBC (iiyunithi zokutshaja) zezithuthi ezintsha zamandla. Izixhobo zeSiC zinokunciphisa ubunzima kunye nomthamo wezixhobo zePCU, zinciphise ukulahleka kweswitshi, kwaye ziphucule ubushushu bokusebenza kunye nokusebenza kakuhle kwenkqubo yezixhobo; Kunokwenzeka kwakhona ukwandisa inqanaba lamandla eyunithi, ukwenza lula ulwakhiwo lwesekethe, ukuphucula uxinano lwamandla, kunye nokwandisa isantya sokutshaja ngexesha lokutshaja kwe-OBC. Okwangoku, iinkampani ezininzi zeemoto kwihlabathi liphela zisebenzise i-silicon carbide kwiimodeli ezininzi, kwaye ukwamkelwa okukhulu kwe-silicon carbide kuye kwaba ngumkhwa.

Xa iiseramikhi ze-silicon carbide zisetyenziswa njengezixhobo eziphambili zokuthwala izinto kwinkqubo yokuvelisa iiseli ze-photovoltaic, iimveliso ezivelayo ezifana nezixhaso zeenqanawa, iibhokisi zeenqanawa, kunye nezihlanganisi zepayipi zinozinzo oluhle lobushushu, aziguquguquki xa zisetyenziswa kumaqondo obushushu aphezulu, kwaye azivelisi ungcoliseko oluyingozi. Zingathatha indawo yezixhaso zeenqanawa ze-quartz ezisetyenziswa rhoqo, iibhokisi zeenqanawa, kunye nezihlanganisi zepayipi, kwaye zinezibonelelo ezinkulu zeendleko.

Ukongeza, amathuba emarike yezixhobo zamandla ze-silicon carbide ze-photovoltaic abanzi. Izixhobo ze-SiC zinokumelana okuphantsi, i-gate charge, kunye neempawu ze-recoverage charge ezibuyela umva. Ukusebenzisa i-SiC Mosfet okanye i-SiC Mosfet kunye ne-SiC SBD photovoltaic inverters kunokunyusa ukusebenza kokuguqulwa ukusuka kwi-96% ukuya ngaphezulu kwe-99%, kunciphise ukulahleka kwamandla ngaphezulu kwe-50%, kwaye kwandise ubomi bomjikelo wezixhobo ngamaxesha angama-50.

Ukwenziwa kwee-ceramics ze-silicon carbide kunokulandelwa emva kwiminyaka yoo-1890, xa i-silicon carbide yayisetyenziswa kakhulu kwizinto zokugaya ngoomatshini kunye nezinto ezichaseneyo. Ngophuhliso lwetekhnoloji yemveliso, iimveliso ze-SiC zobuchwepheshe obuphezulu ziye zaphuhliswa kakhulu, kwaye amazwe kwihlabathi liphela anikela ingqalelo engakumbi ekuphuhlisweni kwee-ceramics eziphambili. Asenelisekanga kukulungiswa kwee-ceramics ze-silicon carbide zendabuko. Amashishini avelisa ii-ceramics zobuchwepheshe obuphezulu aphuhliswa ngokukhawuleza, ngakumbi kumazwe aphuhlileyo apho le nto ibaluleke ngakumbi. Abavelisi bamanye amazwe ikakhulu baquka iSaint Gobain, 3M, CeramTec, IBIDEN, Schunk, Narita Group, Toto Corporation, CoorsTek, Kyocera, Aszac, Japan Jingke Ceramics Co., Ltd., Japan Special Ceramics Co., Ltd., IPS Ceramics, njl.

Uphuhliso lwe-silicon carbide eTshayina belusemva kwexesha xa luthelekiswa namazwe aphuhlileyo afana neYurophu neMelika. Ukususela oko kwakhiwa isithando sokuqala semizi-mveliso sokuvelisa i-SiC kwiFirst Grinding Wheel Factory ngoJuni 1951, iTshayina yaqala ukuvelisa i-silicon carbide. Abavelisi basekhaya beeseramiki ze-silicon carbide bagxile kakhulu kwiSixeko saseWeifang, kwiPhondo laseShandong. Ngokutsho kweengcali, oku kungenxa yokuba amashishini endawo okumba amalahle ajongene nokungaphumeleli kwaye afuna utshintsho. Ezinye iinkampani ziye zazisa izixhobo ezifanelekileyo ezivela eJamani ukuqala uphando kunye nokuvelisa i-silicon carbide.I-ZPC yenye yezona nkampani zinkulu zokwenza i-reaction sintered silicon carbide.

Ixesha leposi: Novemba-09-2024