I-Silicon carbide (SiC) ikhombisa ukumelana nokugqwala okumangalisayo ngenxa yezakhiwo zayo eziyingqayizivele zomzimba nezamakhemikhali.

Ngokuphathelene nokumelana nokuguguleka, ubulukhuni be-Mohs be-silicon carbide bungafinyelela ku-9.5, okwesibili kuphela ngemva kwe-diamond ne-boron nitride. Ukumelana kwayo nokuguguleka kufana nokuphindwe izikhathi ezingu-266 kunokwensimbi ye-manganese kanye nokuphindwe izikhathi ezingu-1741 kunokwensimbi ephezulu ye-chromium.

Ngokuphathelene nokumelana nokugqwala, i-silicon carbide inokuqina okuphezulu kakhulu kwamakhemikhali futhi ikhombisa ukumelana okuhle kakhulu nama-asidi aqinile, ama-alkali, kanye nezixazululo zikasawoti. Okwamanje, i-silicon carbide nayo inokumelana okuphezulu kokugqwala nezinsimbi ezincibilikisiwe njenge-aluminium ne-zinc, futhi ivame ukusetshenziswa ezitsheni ezivuthayo kanye nezikhunta embonini yensimbi.

Njengamanje, i-silicon carbide ehlanganiswe nesakhiwo esiqinile kanye nokungangeni kwamakhemikhali kwayo kuye kwasetshenziswa kabanzi ezimbonini ezifana nezezimayini, insimbi, kanye namakhemikhali, okuba ukukhetha okuhle kwezinto ngaphansi kwezimo zokusebenza ezimbi kakhulu.

| izinto | ukumelana nokuguguleka | ukumelana nokugqwala | ukusebenza kwezinga lokushisa eliphezulu | Ezomnotho (isikhathi eside) |

| I-silicon carbide | Kuphezulu kakhulu | Kuqine kakhulu | Kuhle kakhulu (<1600℃) | Phezulu |

| Izinto zobumba ze-Alumina | Phezulu | Uqinile | Isilinganiso< 1200 ℃) | Okuphakathi nendawo |

| Ingxubevange yensimbi | Okuphakathi nendawo | Kubuthakathaka (kudinga ukumbozwa) | Ibuthakathaka (ithambekele ekufakweni kwe-oxidation) | Kubuthakathaka |

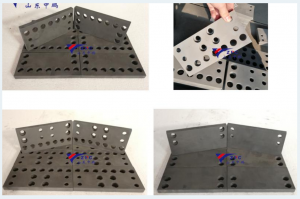

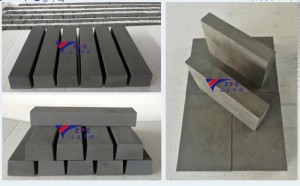

Ibhulokhi elingagugi le-silicon carbidekuyisigaba esibalulekile emikhiqizweni ye-silicon carbide. Izakhiwo ze-silicon carbide ezingagugi futhi ezingagqwali zenza ukuthi isetshenziswe kabanzi emishinini yokugaya efana nama-crusher emayini kanye nama-ball mill, okunciphisa ukushintshwa kwemishini njalo okubangelwa ukuguguleka futhi ngaleyo ndlela kunciphisa izindleko zokugcinwa komshini.

Okulandelayo ukuqhathanisa phakathi kwamabhulokhi amelana nokuguguleka e-silicon carbide namanye amabhulokhi amelana nokuguguleka ezinto zendabuko:

| Ukuqina Nokumelana Nokugqoka | Ibhulokhi elingagugi le-silicon carbide | Izinto zendabuko |

| Ukuqina Nokumelana Nokugqoka | Ubulukhuni be-Mohs 9.5, ukumelana nokuguguleka okunamandla kakhulu (impilo yanda ngokuphindwe ka-5-10) | Insimbi ecijile ene-chromium ephezulu inobulukhuni obuphansi (HRC 60~65), kanti i-alumina ceramics ivame ukuqhekeka kalula |

| Ukumelana nokugqwala | Imelana nama-asidi aqinile nama-alkali | Izinsimbi zivame ukugqwala, kanti i-alumina inokumelana okujwayelekile kwe-asidi |

| Ukuqina kokushisa okuphezulu | Ukumelana nokushisa okungu-1600 ℃, okungagcini ngokushisa emazingeni okushisa aphezulu | Insimbi ithambekele ekuguqukeni emazingeni okushisa aphezulu, kuyilapho i-alumina inokumelana nokushisa okungu-1200 ℃ kuphela. |

| Ukuqhuba kwe-thermal | 120 W/m · K, ukushabalalisa ukushisa okusheshayo, ukumelana nokushaqeka kokushisa | Insimbi inomoya omuhle wokushisa kodwa ithambekele ekushiseni, kuyilapho izinto zobumba ezivamile zinomoya omubi wokushisa |

| Ezomnotho | Isikhathi eside sokuphila kanye nezindleko eziphansi jikelele | Izinsimbi zidinga ukushintshwa njalo, izinto zobumba ziyaphuka, futhi izindleko zesikhathi eside ziphakeme |

Isikhathi sokuthunyelwe: Mashi-18-2025