Silicon carbide (SiC) yana da juriya sosai ga lalacewa da tsatsa saboda keɓancewarsa ta musamman ta zahiri da sinadarai.

Dangane da juriyar lalacewa, ƙarfin Mohs na silicon carbide zai iya kaiwa 9.5, wanda ya fi na lu'u-lu'u da boron nitride. juriyar lalacewa daidai yake da sau 266 na ƙarfe manganese da kuma sau 1741 na ƙarfe mai yawan chromium.

Dangane da juriyar tsatsa, silicon carbide yana da matuƙar ƙarfin sinadarai kuma yana da kyakkyawan juriya ga acid mai ƙarfi, alkalis, da kuma maganin gishiri. A halin yanzu, silicon carbide yana da juriya mai ƙarfi ga ƙarfe mai narkewa kamar aluminum da zinc, kuma ana amfani da shi sosai a cikin bututun ƙarfe da molds a masana'antar ƙarfe.

A halin yanzu, an yi amfani da silicon carbide tare da tsarin da ya yi tsauri da kuma rashin ingancin sinadaransa sosai a masana'antu kamar hakar ma'adinai, ƙarfe, da sinadarai, wanda hakan ya zama zaɓi mafi kyau a cikin mawuyacin yanayi na aiki.

| abu | juriyar lalacewa | juriyar tsatsa | yawan zafin jiki | Tattalin Arziki (na dogon lokaci) |

| Silicon carbide | Mai matuƙar girma | Ƙarfi sosai | Madalla (<1600℃) | Babban |

| Tukwanen Alumina | Babban | Mai ƙarfi | Matsakaicin (<1200℃) | Matsakaici |

| Gashin ƙarfe | Matsakaici | Mai rauni (yana buƙatar shafa) | Mai rauni (mai yuwuwa ga iskar shaka) | Mai rauni |

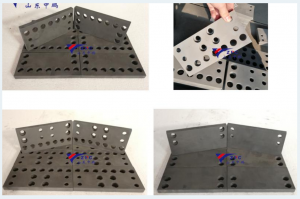

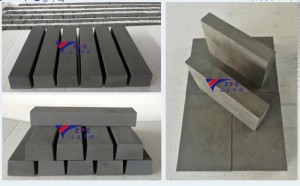

Toshe mai jure wa lalacewa ta silicon carbideRarraba abu ne mai mahimmanci a cikin samfuran silicon carbide. Abubuwan da ke jure lalacewa da kuma jure tsatsa na silicon carbide suna sa a yi amfani da shi sosai a cikin kayan niƙa kamar injin niƙa ma'adinai da injin niƙa ƙwallo, wanda ke rage yawan maye gurbin kayan aiki da lalacewa ke haifarwa, don haka rage farashin kula da injin.

Ga kwatancen da ke ƙasa tsakanin tubalan da ke jure wa lalacewa ta silicon carbide da sauran tubalan da ke jure wa lalacewa ta gargajiya:

| Taurin da Juriyar Sawa | Toshe mai jure wa lalacewa ta silicon carbide | Kayan gargajiya |

| Taurin da Juriyar Sawa | Taurin Mohs 9.5, juriyar lalacewa mai ƙarfi sosai (rayuwar ta ƙaru da sau 5-10) | Babban ƙarfe mai simintin chromium yana da ƙarancin tauri (HRC 60~65), kuma yumbun alumina suna da saurin karyewa. |

| Juriyar lalata | Yana jure wa acid mai ƙarfi da alkalis | Karfe yana da saurin lalacewa, yayin da alumina ke da matsakaicin juriya ga acid |

| Kwanciyar hankali mai yawa | Juriyar zafin jiki na 1600 ℃, ba ya yin oxidizing a yanayin zafi mai yawa | Karfe yana da saurin lalacewa a yanayin zafi mai yawa, yayin da alumina ke da juriyar zafin jiki na 1200 ℃ kawai |

| Maida wutar lantarki ta thermal | 120 W/m · K, saurin watsa zafi, juriya ga girgizar zafi | Karfe yana da kyakkyawan juriyar zafi amma yana da saurin kamuwa da iskar shaka, yayin da tukwane na yau da kullun ba su da isasshen juriyar zafi. |

| tattalin arziki | Tsawon rai da ƙarancin farashi gabaɗaya | Karfe yana buƙatar maye gurbinsa akai-akai, yumbu yana da rauni, kuma farashi mai tsawo yana da yawa |

Lokacin Saƙo: Maris-18-2025