Silicon carbide (SiC) inodzivirira kusakara uye ngura zvakanyanya nekuda kwehunhu hwayo hwepanyama uye hwemakemikari.

Panyaya yekusapera, kuomarara kweMohs kwesilicon carbide kunogona kusvika 9.5, kuri kwechipiri kune diamond ne boron nitride. Kusapera kwayo kwakaenzana nekupetwa ka266 kwesimbi yemanganese uye ka1741 kupfuura simbi ine chromium yakawanda.

Panyaya yekudzivirira ngura, silicon carbide ine kugadzikana kwakanyanya kwemakemikari uye inodzivirira zvakanyanya kune maacid akasimba, alkalis, uye munyu. Panguva imwecheteyo, silicon carbide inodzivirirawo ngura zvakanyanya kune simbi dzakanyungudutswa dzakadai sealuminium ne zinc, uye inowanzoshandiswa muzvigadziko zvesimbi uye molds muindasitiri yesimbi.

Parizvino, silicon carbide pamwe chete nechimiro chayo chakasimba uye kusashanda kwayo kwemakemikari zvave zvichishandiswa zvakanyanya mumaindasitiri akadai semigodhi, simbi, uye makemikari, zvichiva sarudzo yakanaka yezvinhu mumamiriro ekushanda akaomarara.

| zvinhu | kuramba kupfeka | kuramba ngura | kushanda kwekupisa kwakanyanya | Zvehupfumi (zvenguva refu) |

| Silicon carbide | Yakakwira zvakanyanya | Yakasimba zvikuru | Yakanaka kwazvo (<1600℃) | Yakakwirira |

| Zviumbwa zveAlumina | Yakakwirira | Simba | Avhareji (<1200℃) | Pakati nepakati |

| Chiwanikwa chesimbi | Pakati nepakati | Kusasimba (kunoda kuputirwa) | Kusasimba (kunogona kuoxidation) | Kusasimba |

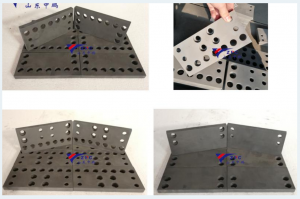

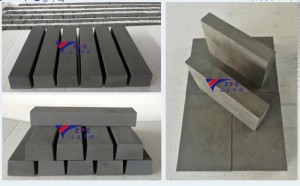

Silicon carbide isingapfeki bhurokoimhando yakakosha muzvigadzirwa zvesilicon carbide. Hunhu hwesilicon carbide hunodzivirira kupera uye hunodzivirira ngura hunoita kuti ishandiswe zvakanyanya mumidziyo yekukuya yakaita semigodhi yekupwanya uye mill mills, zvichideredza kutsiva michina nguva nenguva kunokonzerwa nekusakara uye nokudaro zvichideredza mari yekugadzirisa michina.

Zvinotevera kuenzanisa pakati pezvigadziko zvinodzivirira kusakara zvesilicon carbide nezvimwe zvinhu zvechinyakare zvinodzivirira kusakara:

| Kuoma uye Kuramba Kupfeka | Silicon carbide isingapfeki bhuroko | Zvinhu zvechinyakare |

| Kuoma uye Kuramba Kupfeka | Kuomarara kweMohs 9.5, kuramba kupfeka kwakasimba kwazvo (hupenyu hwakawedzera ne5-10 times) | Simbi yakakandwa ine chromium yakawanda ine kuomarara kushoma (HRC 60~65), uye alumina ceramics inogona kutsemuka nekupwanyika. |

| Kuramba ngura | Haipindi maasidhi akasimba uye alkali | Simbi dzinogona kubatwa nengura, nepo alumina ichiramba acid zvakanyanya |

| Kugadzikana kwekupisa kwakanyanya | Kuramba tembiricha kwe1600 ℃, kusaoxidize pakupisa kwakanyanya | Simbi inogona kuchinja kana tembiricha yakakwira, nepo alumina ichiramba tembiricha ye1200 ℃ chete. |

| Kufambisa kwekupisa | 120 W/m · K, kupisa kunopera nekukurumidza, kuramba kupisa | Simbi ine mafambiro akanaka ekupisa asi inokurumidza kuoxidation, nepo zviumbwa zvesimbi zvakajairika zvisina mafambiro asina kunaka ekupisa |

| Zvehupfumi | Nguva refu yehupenyu uye mutengo wakaderera wezvose | Simbi dzinoda kutsiviwa nguva nenguva, zviumbwa zvesimbi zvinopera simba, uye mitengo yenguva refu yakakwira |

Nguva yekutumira: Kurume-18-2025