I-silicon carbide (i-SiC) ibonakalisa ukuguguleka okugqwesileyo kunye nokumelana nokugqwala ngenxa yeempawu zayo ezizodwa zomzimba nezekhemikhali.

Ngokuphathelele ukumelana nokuguguleka, ubunzima be-Mohs be-silicon carbide bunokufikelela kwi-9.5, bulandela i-diamond kunye ne-boron nitride kuphela. Ukumelana kwayo nokuguguleka kufana nokuphindwe ka-266 kune-manganese steel kunye nokuphindwe ka-1741 kune-chromium cast iron ephezulu.

Ngokuphathelele ukumelana nokugqwala, i-silicon carbide inozinzo oluphezulu kakhulu lweekhemikhali kwaye ibonakalisa ukumelana okuhle kakhulu nee-asidi ezinamandla, ii-alkalis, kunye nezisombululo zetyuwa. Okwangoku, i-silicon carbide ikwanokumelana okuphezulu kokugqwala kwiintsimbi ezinyibilikisiweyo ezifana ne-aluminium kunye ne-zinc, kwaye isetyenziswa kakhulu kwii-crucibles kunye nee-molds kushishino lwe-metallurgical.

Okwangoku, i-silicon carbide edityaniswe nesakhiwo esiqinileyo kunye nokungangeni kwayo kweekhemikhali isetyenziswa kakhulu kumashishini afana nemigodi, intsimbi, kunye neekhemikhali, ibe lolona khetho lufanelekileyo lwezinto phantsi kweemeko zokusebenza ezinzima.

| izinto | ukumelana nokuguguleka | ukumelana nokugqwala | ukusebenza kobushushu obuphezulu | Ezoqoqosho (ixesha elide) |

| I-silicon carbide | Iphezulu kakhulu | Yomelele kakhulu | Igqwesile (<1600℃) | Phezulu |

| Iiseramikhi zeAlumina | Phezulu | Unamandla | Umndilili< 1200℃) | Phakathi |

| Ingxubevange yesinyithi | Phakathi | Ubuthathaka (ifuna ukugqunywa) | Ubuthathaka (inokutsaleleka kwi-oxidation) | Ubuthathaka |

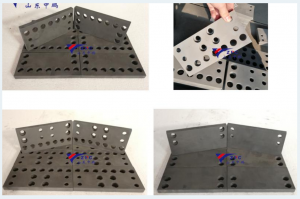

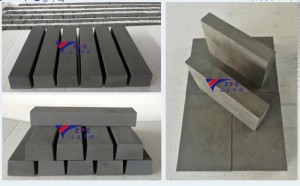

Ibhloko engagugiyo ye-silicon carbideluluhlu olubalulekileyo kwiimveliso ze-silicon carbide. Iimpawu ze-silicon carbide ezingagugiyo nezingagugiyo zenza ukuba isetyenziswe kakhulu kwizixhobo zokugaya ezifana nee-mine crushers kunye nee-ball mills, nto leyo enciphisa ukutshintshwa kwezixhobo rhoqo okubangelwa kukuguguleka kwaye ngaloo ndlela kunciphisa iindleko zokugcinwa koomatshini.

Oku kulandelayo kukuthelekisa phakathi kweebhloko ezinganyangekiyo zesilicon carbide kunye nezinye iibhloko ezinganyangekiyo zezinto zemveli:

| Ukuqina kunye nokumelana nokunxiba | Ibhloko engagugiyo ye-silicon carbide | Izixhobo zemveli |

| Ukuqina kunye nokumelana nokunxiba | Ubunzima beMohs 9.5, ukumelana nokuguguleka okunamandla kakhulu (ubomi bunyuke ngama-5-10 amaxesha) | Isinyithi esinobuthi obuphezulu be-chromium sinobunzima obuphantsi (HRC 60~65), kwaye i-alumina ceramics ithanda ukuqhekeka kancinci. |

| Ukumelana nokugqwala | Ayimelani ne-asidi ezinamandla kunye ne-alkali | Iintsimbi zinomngcipheko wokubola, ngelixa i-alumina inokumelana ne-asidi eqhelekileyo |

| Uzinzo lobushushu obuphezulu | Ukumelana nobushushu obuyi-1600 ℃, ukungaxilisi kubushushu obuphezulu | Isinyithi sinokuguquguquka xa kushushu kakhulu, ngelixa i-alumina inokumelana nobushushu obuyi-1200 ℃ kuphela. |

| Ukuqhuba kobushushu | 120 W/m · K, ukusasaza ubushushu ngokukhawuleza, ukumelana noxinzelelo lobushushu | Isinyithi sinomoya ofanelekileyo wokushisa kodwa sinomoya ongcolileyo, ngelixa iiseramikhi eziqhelekileyo zinomoya ophantsi wokushisa. |

| Ezoqoqosho | Ixesha elide lokuphila kunye nexabiso eliphantsi iyonke | Iintsimbi zifuna ukutshintshwa rhoqo, iiseramikhi zibuthathaka, kwaye iindleko zexesha elide ziphezulu |

Ixesha leposi: Matshi-18-2025