Izitsha zobumba ze-silicon carbide (SiC)zaziwa ngamandla azo amangalisayo, ukumelana nokushisa, kanye nokuqina. Lezi zakhiwo zizenza zilungele ukusetshenziswa ezindaweni ezinzima, njengezinjini zezindiza noma imishini yezimboni. Kodwa lezi zinto ezithuthukisiwe zakhiwa kanjani ngempela? Ake sihlaziye inqubo isinyathelo ngesinyathelo.

1. Ukulungiselela Izinto Ezingavuthiwe

Konke kuqala ngempuphu ye-silicon carbide emsulwa kakhulu. Cabanga ngalokhu “njengofulawa” wokubhaka “ikhekhe” le-ceramic. Ukuze uthuthukise izakhiwo zezinto zokugcina, inani elincane lezithasiselo—njenge-aluminium oxide noma ama-boron compounds—liyaxutshwa. Lezi zithasiselo zisebenza njengeglue ezigabeni zakamuva, zisiza izinhlayiya ukuthi zihlangane kahle.

2. Ukubumba i-Ceramic

Impuphu ibe isiguqulwa ibe uhlobo olubumbekayo. Izindlela ezimbili ezivamile zisetshenziswa:

Ukucindezela: Impushana icindezelwa ibe yisimo esithile kusetshenziswa ukucindezela okuphezulu, okufana nokucindezela iqhwa libe yibhola leqhwa.

Ukubumba Ngomjovo: Impushana ixutshwa nesihlanganisi sesikhashana (njenge-wax) ukuze kudalwe ingxube efana nenhlama, efakwa ezikhumbeni zezimo eziyinkimbinkimbi.

Kulesi sigaba, izinto zisabuthakathaka—njengesithombe sesihlabathi esomile—futhi kudingeka “zibhakwe” ukuze ziqine.

3. Inqubo Yokuhlanza

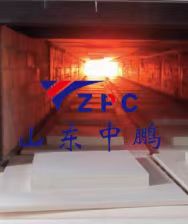

Yilapho umlingo wenzeka khona. I-ceramic emise okwesimo ishiswa esithandweni esikhethekile emazingeni okushisa aphezulu kakhulu (ngokuvamile angaphezu kuka-1,800°C). Ngesikhathi sokushisa, kwenzeka izinto ezimbili ezibalulekile:

Isibopho Sezinhlayiya: Izinhlayiya ze-silicon carbide ziyasondelana, zisusa izikhala futhi zakhe isakhiwo esiqinile.

Izithasiselo Ziyasebenza: Izithako ezengeziwe ziyancibilika kancane, zidale “ibhuloho” phakathi kwezinhlayiya ukuze kuqiniswe ukuqina.

Indawo engaphakathi kwesithando ilawulwa ngokucophelela—ngezinye izikhathi igcwele amagesi angasebenzi—ukuvimbela ukusabela okungafuneki.

4. Izinto Zokuqeda

Ngemva kokusila, i-ceramic ingase ithole ukwelashwa okwengeziwe ukuze ithuthukise ukusebenza kwayo:

Ukupholisha: Kwezicelo ezidinga izindawo ezibushelelezi (isb., izivalo noma amabheringi).

Ukugqoka: Isendlalelo esincane sokuvikela (njenge-silicon nitride) singangezwa ukuze kwandiswe ukumelana nokuguguleka.

Umshini: Ukusika noma ukubhoboza okunembile ukuze kufezwe ubukhulu bokugcina.

Kungani Le Nqubo Ibalulekile

Imfihlo yamandla e-silicon carbide itholakala endleleni ama-athomu ayo ahlangana ngayo ngesikhathi sokushiswa. Inqubo yokushisa okuphezulu idala inethiwekhi yezibopho eziqinile ze-silicon-carbon, ezimelana nokushisa, ukugqwala, kanye nokucindezeleka ngokomzimba. Izithasiselo kanye nokulawula izinga lokushisa okunembile kuqinisekisa ukuthi umkhiqizo wokugcina awugcini nje ngokuba nzima kodwa futhi uqine ngokwanele ukumelana nokuqhekeka.

Isithombe Esikhulu Kakhulu

Kusukela kuma-turbine asezingeni eliphezulu kuya ezinhlelweni zokulawula ukungcola, i-silicon carbide ceramics idlala indima ebalulekile kwezobuchwepheshe besimanje. Nakuba inqubo yokukhiqiza iyinkimbinkimbi, yile bhalansi ecophelelayo yesayensi nobunjiniyela eguqula i-powder elula ibe yinto ekwazi ukumelana nezimo ezinzima kakhulu.

Njengoba ucwaningo luqhubeka, izindlela ezintsha—njengokunyathelisa izinto zobumba nge-3D—ziyavela, zithembisa ukusetshenziswa okusha kakhulu kwalokhu okumangalisayo.

Isikhathi sokuthunyelwe: Mashi-19-2025