Zvigadzirwa zvesimbi zvesilicon carbide (SiC)dzinozivikanwa nesimba radzo rinoshamisa, dzinodzivirira kupisa, uye kugara kwenguva refu. Hunhu uhwu hunoita kuti dzive dzakakodzera kushandiswa munzvimbo dzakaoma, senge mainjini emuchadenga kana michina yeindasitiri. Asi zvinhu izvi zvemhando yepamusoro zvinogadzirwa sei chaizvo? Ngatitsanangure maitiro acho nhanho nhanho.

1. Kugadzirira Zvinhu Zvisina Kugadzirwa

Zvese zvinotanga neupfu hwesilicon carbide hwakachena kwazvo. Funga nezveizvi se "hupfu" hwekubika "keke" receramic. Kuti uvandudze hunhu hwechinhu chekupedzisira, huwandu hudiki hwezvinhu zvinowedzerwa - senge aluminium oxide kana boron compounds - zvinosanganiswa. Izvi zvinowedzerwa zvinoshanda seglue panguva dzekupedzisira, zvichibatsira kuti zvidimbu zvibatane zvinobudirira.

2. Kuumba Ceramic

Upfu hwacho hunozoshandurwa kuita chimiro chinoumbwa. Nzira mbiri dzinoshandiswa:

Kudzvanya: Hupfu hunodzvanywa kuita chimiro chakati uchishandisa kudzvanywa kwakanyanya, zvakafanana nekudzvanya chando kuita bhora rechando.

Kugadzira Jekiseni: Hupfu hunosanganiswa nechinobatanidza kwenguva pfupi (senge wakisi) kuti pave nemusanganiswa wakaita sehupfu, uyo unopinzwa muzviumbwa zvemaumbirwo akaomarara.

Padanho iri, chinhu chacho chichiri kusimba—sechifananidzo chejecha rakaoma—uye chinofanira “kubikwa” kuti chive chakasimba.

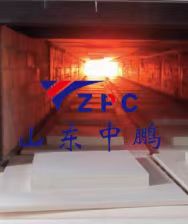

3. Maitiro Ekuchenesa

Apa ndipo panoitika mashiripiti. Ceramic yakaita sechiumbwa inopiswa muchoto chakakosha pakupisa kwakanyanya (kazhinji pamusoro pe1,800°C). Panguva yekupiswa, zvinhu zviviri zvakakosha zvinoitika:

Particles Bond: Tsanga dzesilicon carbide dzinokura pedyo, dzichibvisa mipata uye dzichigadzira chimiro chakasimba.

Zvinowedzerwa Zvinoshanda: Makemikoro akawedzerwa anonyunguduka zvishoma, zvichiita kuti pave ne "bhiriji" pakati pezvikamu kuti zviwedzere kusimba.

Mamiriro ezvinhu ari mukati mechoto anodzorwa nokungwarira—dzimwe nguva anozadzwa nemagasi asina simba—kudzivirira migumisiro isingadiwe.

4. Kupedzisa Kugadzirisa

Mushure mekupiswa, ceramic inogona kupiwa mamwe marapirwo ekuvandudza mashandiro ayo:

Kupolisha: Kune mashandisirwo anoda nzvimbo dzakatsetseka (semuenzaniso, zvisimbiso kana mabheringi).

Kupfeka: Chidziviriro chakatetepa (senge silicon nitride) chinogona kuwedzerwa kuti chiwedzere kuramba kupfekwa.

Kugadzira: Kucheka kana kuchera nemazvo kuti uwane saizi yekupedzisira.

Nei Maitiro Aya Achikosha

Chakavanzika chesimba resilicon carbide chiri pakuti maatomu ayo anobatana sei panguva yekupiswa. Maitiro ekupisa kwakanyanya anogadzira network ye silicon-carbon bonds dzakasimba, idzo dzinoramba kupisa, ngura, uye kushushikana kwemuviri. Zvinowedzerwa uye kudzora tembiricha kwakanyatsojeka zvinoita kuti chigadzirwa chekupedzisira chisave chakaoma chete asiwo chakasimba zvakakwana kuti chisatsemuke.

Mufananidzo Mukuru

Kubva kumaturbine emhando yepamusoro kusvika kumasystem ekudzora kusvibiswa, silicon carbide ceramics inoita basa rakakosha mutekinoroji yemazuva ano. Kunyange hazvo maitiro ekugadzira akaomarara, ndiko kuenzana kwakanyatsoitwa kwesainzi neinjiniya ndiko kunoshandura hupfu hwakareruka kuita chinhu chinokwanisa kutsungirira mamiriro akaomarara.

Sezvo tsvakurudzo ichifambira mberi, nzira itsva—dzakadai sekudhinda zvinhu zvesimbi mu3D—dziri kubuda, zvichivimbisa kushandiswa kwakawanda kwezvinhu izvi zvinoshamisa.

Nguva yekutumira: Kurume-19-2025