Iiseramikhi zeSilicon carbide (SiC)zaziwa ngamandla azo amangalisayo, ukumelana nobushushu, kunye nokuqina. Ezi mpawu zizenza zilungele ukusetyenziswa kwiindawo ezinzima, njengeenjini zeenqwelo-moya okanye oomatshini bemizi-mveliso. Kodwa ezi zinto ziphucukileyo zenziwe njani kanye kanye? Masihlalutye inkqubo inyathelo ngenyathelo.

1. Ukulungiswa kwezinto eziluhlaza

Konke kuqala ngomgubo we-silicon carbide ococekileyo kakhulu. Cinga ngale nto njengomgubo wokubhaka “ikhekhe” yeseramikhi. Ukuphucula iimpawu zezinto zokugqibela, kuxutywa izixa ezincinci zezongezo—ezifana ne-aluminium oxide okanye ii-boron compounds. Ezi zongezo zisebenza njengeglue kwizigaba zamva nje, zinceda amasuntswana ukuba adibane ngempumelelo.

2. Ukubumba iCeramic

Emva koko umgubo uguqulwa ube yimo enokubumbeka. Iindlela ezimbini eziqhelekileyo zisetyenziswa:

Ukucinezela: Umgubo ucinezelwa ube yimo ethile kusetyenziswa uxinzelelo oluphezulu, okufana nokuxinana kwekhephu libe yibhola yekhephu.

Ukubumba Ngenaliti: Umgubo uxutywa nesixhobo sokubopha sexeshana (njengewax) ukwenza umxube ofana nentlama, ofakwa kwiimolds ukuze kubekho iimilo ezintsonkothileyo.

Kule nqanaba, izinto zisabuthathaka—njengomfanekiso oqingqiweyo wesanti eyomileyo—kwaye kufuneka “zibhakwe” ukuze zomelele.

3. Inkqubo yokuHlamba

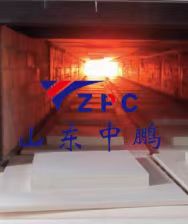

Kulapho ke kwenzeka khona umlingo. I-ceramic emile itshiswa kwisithando esikhethekileyo kumaqondo obushushu aphezulu kakhulu (ngamaxesha amaninzi ngaphezulu kwe-1,800°C). Ngexesha lokutshiswa, izinto ezimbini ezibalulekileyo zenzeka:

I-Particles Bond: Iinkozo ze-silicon carbide ziyasondelana, zisusa izikhewu kwaye zenze isakhiwo esiqinileyo.

Izongezo ziyasebenza: Iikhompawundi ezongeziweyo zinyibilika kancinci, zenze "ibhulorho" phakathi kwamasuntswana ukuze komelezwe ukuqina.

Imeko-bume engaphakathi kwesithando ilawulwa ngononophelo—ngamanye amaxesha izaliswe ziigesi ezingasebenziyo—ukuthintela iimpembelelo ezingafunekiyo.

4. Izinto zokugqiba

Emva kokusila, i-ceramic isenokunyangwa ngakumbi ukuphucula ukusebenza kwayo:

Ukupolisha: Kwizicelo ezifuna iindawo ezigudileyo (umz., izitywini okanye iibheringi).

Ukwaleka: Umaleko obhityileyo wokukhusela (njenge-silicon nitride) ungongezwa ukuze womeleze ukuguguleka.

Umatshini: Ukusika okanye ukubhola ngokuchanekileyo ukuze kufezekiswe imilinganiselo yokugqibela.

Kutheni le nkqubo ibalulekile

Imfihlo yamandla e-silicon carbide ikwindlela ii-athomu zayo ezidibana ngayo ngexesha lokusila. Inkqubo yobushushu obuphezulu idala uthungelwano lweebhondi ze-silicon-carbon ezinamandla, ezimelana nobushushu, ukugqwala, kunye noxinzelelo lomzimba. Izongezo kunye nolawulo oluchanekileyo lobushushu ziqinisekisa ukuba imveliso yokugqibela ayinzima nje kuphela kodwa ikwanzima ngokwaneleyo ukumelana nokuqhekeka.

Umfanekiso Omkhulu

Ukususela kwiiturbines ezisemgangathweni ophezulu ukuya kwiinkqubo zokulawula ungcoliseko, ii-silicon carbide ceramics zidlala indima ebalulekileyo kubuchwepheshe banamhlanje. Nangona inkqubo yokuvelisa inzima, yile bhalansi ecokisekileyo yesayensi kunye nobunjineli eguqula i-powder elula ibe yinto ekwaziyo ukumelana neemeko ezinzima.

Njengoko uphando luqhubeka, iindlela ezintsha—ezifana nokuprintwa kwe-3D kwezinto zodongwe—ziyavela, zithembisa ukusetyenziswa okutsha ngakumbi kwezi zinto zimangalisayo.

Ixesha lokuthumela: Matshi-19-2025