Silicon carbide (SiC) yumburaan san su don ƙarfin ban mamaki, juriya na zafi, da karko. Waɗannan kaddarorin sun sa su dace don amfani a cikin wurare masu tauri, kamar injunan sararin samaniya ko injinan masana'antu. Amma ta yaya ainihin waɗannan kayan haɓaka suka ƙirƙira? Bari mu rushe tsarin mataki-mataki.

1.Raw Material Shiri

Duk yana farawa da tsaftataccen siliki carbide foda. Ka yi la'akari da wannan a matsayin "gari" don yin burodin yumbu "cake." Don inganta kayan abu na ƙarshe, ƙananan abubuwan ƙarawa-kamar aluminum oxide ko boron mahadi-ana haɗe su a ciki. Wadannan additives suna aiki kamar manne a lokacin matakai na gaba, suna taimakawa barbashi su haɗa da kyau.

2. Siffata yumbura

Ana juya foda ta zama nau'i mai yuwuwa. Ana amfani da hanyoyin gama gari guda biyu:

Latsawa: Ana matse foda zuwa wani takamaiman siffa ta amfani da matsi mai ƙarfi, kama da haɗa dusar ƙanƙara a cikin ƙwallon dusar ƙanƙara.

Gyaran Injection: Ana haɗe foda tare da ɗaure na ɗan lokaci (kamar kakin zuma) don ƙirƙirar cakuda mai-kamar kullu, wanda ake allura a cikin gyare-gyare don hadaddun siffofi.

A wannan mataki, kayan har yanzu yana da rauni-kamar busassun yashi sassaka-kuma yana buƙatar "gasa" don zama mai ƙarfi.

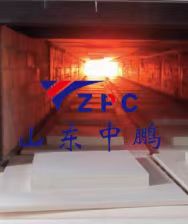

3. Tsarin Tsarkakewa

A nan ne sihiri ya faru. Ana dumama yumbu mai siffa a cikin tanderu ta musamman a yanayin zafi mai tsananin zafi (sau da yawa sama da 1,800°C). A lokacin sintering, abubuwa biyu masu mahimmanci suna faruwa:

Barbashi Bond: The silicon carbide hatsi girma kusa, kawar da gibi da samar da ingantaccen tsari.

Additives Aiki: Abubuwan da aka ƙara suna narkewa kaɗan, ƙirƙirar "gada" tsakanin barbashi don haɓaka tauri.

Yanayin da ke cikin tanderun ana sarrafa shi a hankali-wani lokaci yana cika da iskar gas-don hana halayen da ba a so.

4. Ƙarshen Ƙarfafawa

Bayan sintering, yumbu na iya samun ƙarin jiyya don inganta aikin sa:

goge: Don aikace-aikacen da ke buƙatar filaye masu santsi (misali, hatimi ko bearings).

Shafi: Za'a iya ƙara ƙaramin kariya na bakin ciki (kamar silicon nitride) don haɓaka juriya.

Machining: Daidaitaccen yanke ko hakowa don cimma girma na ƙarshe.

Me Yasa Wannan Tsari Yayi Mahimmanci

Sirrin ƙarfin silicon carbide ya ta'allaka ne kan yadda atom ɗin sa ke haɗawa yayin sintering. Tsarin zafin jiki mai zafi yana haifar da hanyar sadarwa mai karfi na silicon-carbon bond, wanda ke da tsayayya ga zafi, lalata, da damuwa na jiki. Abubuwan da ake ƙarawa da madaidaicin sarrafa zafin jiki suna tabbatar da samfurin ƙarshe ba kawai mai wuya bane amma kuma yana da ƙarfi don tsayayya da fatattaka.

Babban Hoto

Daga manyan injin injin injin injin lantarki zuwa tsarin sarrafa gurɓataccen gurɓataccen iska, yumbu na silicon carbide yana taka muhimmiyar rawa a fasahar zamani. Yayin da tsarin kera ke da sarkakiya, wannan tsantsan ma'auni na kimiyya da aikin injiniya ne ke juyar da foda mai sauƙi zuwa wani abu mai iya jure yanayi mafi tsauri.

Yayin da bincike ya ci gaba, sabbin hanyoyin-kamar bugu na 3D na yumbu-suna tasowa, suna yin alƙawarin ma ƙarin sabbin amfani ga wannan kayan na ban mamaki.

Lokacin aikawa: Maris 19-2025