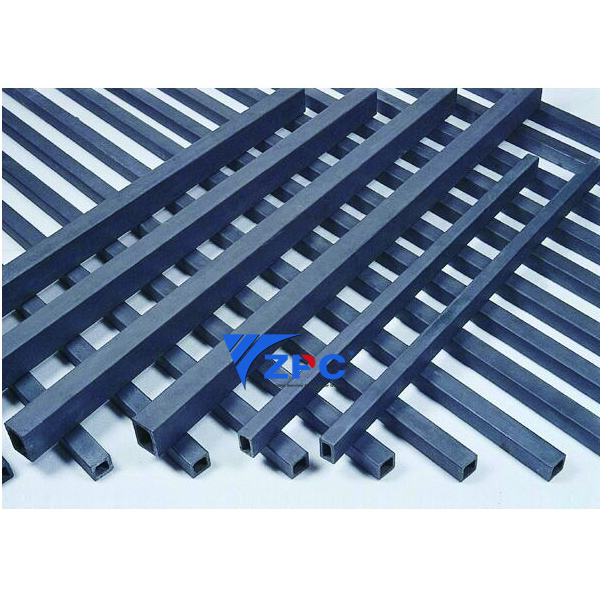

Imiqadi ye-silicon carbide

Iirola zeseramikhi ze-silicon carbide (R-SiC) ezixutywe ne-reaction-sinteredZivele njengezinto ezibalulekileyo kwiinkqubo zanamhlanje zokucubungula ubushushu, ingakumbi ezigqwesileyo ekuveliseni iibhetri ze-lithium, ukuvelisa iiseramikhi eziphambili, kunye nokucocwa kwezinto zemagnethi ngokuchanekileyo. Ezi roller zikhethekileyo zichaza kwakhona imigangatho yokusebenza kwii-oven zoshishino ezinobushushu obuphezulu ngokujongana nemingeni ephambili ekuzinzeni kobushushu kunye nokuqina koomatshini.

Ukusebenza kobushushu obungalinganiyo

Yenzelwe ukusebenza rhoqo kwi-1450-1600°C – iphezulu kakhulu kunee-alumina rollers zemveli – ii-R-SiC rollers zigcina ukuchaneka kobukhulu nokuba ziphantsi kobushushu obugqithisileyo. Ulwakhiwo lwazo olukhethekileyo lwe-microstructure luvumela oku kulandelayo:

• Ukufana okukhawulezayo kokudlulisa ubushushu (±5°C kubude berola)

• Ukumelana nemijikelo yobushushu engaphezulu kwe-100 (1400°C ↔ ubushushu begumbi)

• Akukho kuguquka kokuqhekeka xa kushushu kakhulu

Izicelo ezibalulekileyo zichazwe ngokutsha

1. Ukuveliswa kwebhetri yeLithium

- Ulungelelwaniso oluchanekileyo lokucoca izinto ze-electrode

- Ukuphathwa kwee-cathode ze-NMC/LFP ngaphandle kongcoliseko

- Ukusebenza okuzinzileyo ekunciphiseni umoya

2. Ukucubungula iiCeramics eziPhambili

- Inkxaso engenamagophe kwiithayile ezinkulu (ukuya kuthi ga kwi-1.5×3m)

- Ulawulo oluqhubekayo lwesantya kwimigca yeglasi yezixhobo zangasese

- Ukugqitywa komphezulu ongengophawu (Ra <0.8μm)

3. Ukuveliswa kwezinto zeMagnetic

- Ukujikeleza okungenangcangcazelo kwi-ferrite sintering ejolise kuyo

- Ukungangeni kweekhemikhali kwiindawo ezityebileyo ngehydrogen

Iingenelo zokusebenza

Umthamo woMthwalo: Ixhasa ubunzima obuyi-3-5 × obukhulu ngobude beyunithi nganye xa kuthelekiswa neeroli ze-alloy zesinyithi

Ukumelana nokuguquka: Igcina ukuthe tye okungaphantsi kwe-0.05mm/m emva kweeyure zokusebenza ezili-10,000

Ukusebenza kakuhle kwamandla: Ukusetyenziswa kwamandla esitovini okuncitshisiweyo yi-18-22% ngokusasazwa kobushushu okwenziwe ngcono

Ukuhambelana kweMizi-mveliso eyahlukeneyo: Ingaguquguquka kwii-shuttle kilns, iziko le-roller elinamaleya amaninzi, kunye neziko ze-hybrid tunnel

Uzinzo lwezoQoqosho

Nangona kufuneka utyalo-mali lokuqala oluphezulu ngama-30-40% kunee-roller eziqhelekileyo, izisombululo ze-R-SiC zibonisa oku kulandelayo:

- Izithuba zenkonzo ezinde ngama-70% (iminyaka emi-5-7 xa kuthelekiswa neminyaka emi-2-3)

- Ukukwazi ukuphinda kusetyenziswe nge-90% ngokusebenzisa iinkqubo zokubuyisela ubushushu

- Iindleko zokulungisa eziphantsi ngama-60% ezivela kwiindawo ezinganyangekiyo

Uyilo oluLungele iXesha elizayo

Iirola ze-R-SiC zanamhlanje ngoku ziquka:

- Iigroove zokulandelela ezibhalwe nge-laser zemigca yemveliso ezenzekelayo

- I-porosity enokulungiselelwa ngokwezifiso ukuze kubekho ukuvuleka komoya othile

- Izinzwa zobushushu ezidityanisiweyo zokusebenza kwe-oven ekrelekrele

Olu phuculo lobuchwepheshe lubeka iirola ze-silicon carbide ezisebenzisa i-reaction-sintered njengezinto ezibalulekileyo kwiinkqubo zokufudumeza zoshishino zesizukulwana esilandelayo, nto leyo evumela abavelisi ukuba bafikelele kulawulo lobushushu oluqinileyo, ukuhambelana okuphezulu kwemveliso, kunye nemisebenzi yemveliso ezinzileyo kumacandelo amaninzi obuchwepheshe obuphezulu.

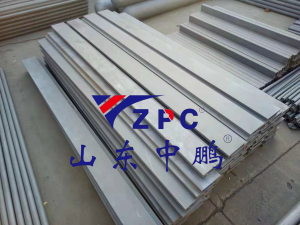

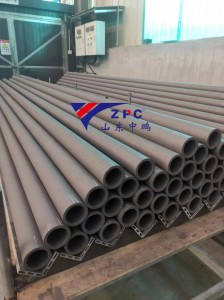

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.