Alwaaxyada silikoon-kaarboon-ka ah

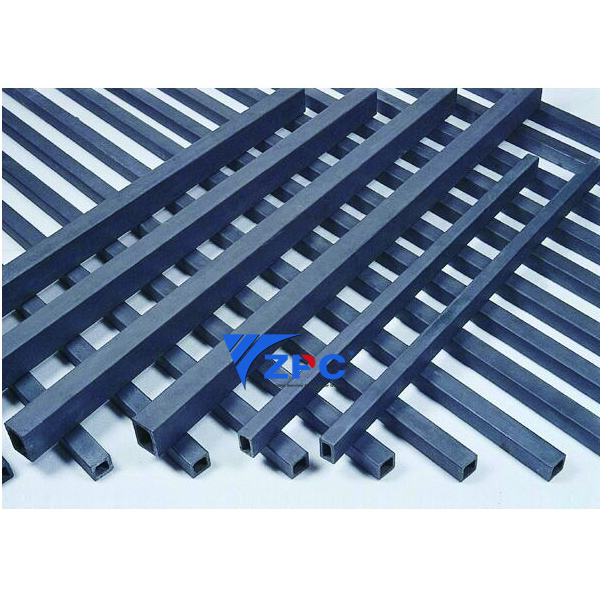

Rulabyada dhoobada ah ee silikoon carbide (R-SiC) ee falcelinta ku shaqeeyaWaxay soo baxeen qaybo muhiim ah oo ka mid ah nidaamyada casriga ah ee farsamaynta kulaylka, gaar ahaan kuwa ugu fiican soo saarista baytariyada lithium, soo saarista dhoobada horumarsan, iyo sintering-ka walxaha magnetic-ka ee saxda ah. Roogyadan gaarka ah waxay dib u qeexaan heerarka waxqabadka ee foornooyinka warshadaha ee heerkulka sare leh iyagoo wax ka qabanaya caqabadaha muhiimka ah ee xasilloonida kulaylka iyo cimri dhererka farsamada.

Waxqabadka Kulaylka ee Aan La Midayn

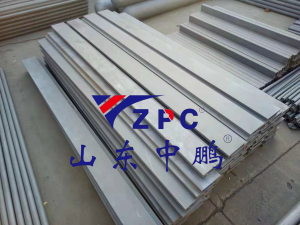

Loogu talagalay inay si joogto ah ugu shaqeyso 1450-1600°C - oo aad uga sarreeya duubayaasha alumina dhaqameed - duubayaasha R-SiC waxay ilaaliyaan saxnaanta cabbirka xitaa marka ay socdaan wareegga kulaylka aadka u daran. Qaab-dhismeedkooda yar yar ee gaarka ah wuxuu awood u siinayaa:

• Isku-mid ahaanshaha wareejinta kulaylka degdegga ah (±5°C dhererka rogrogmada)

• U adkeysan kara wareegyada shoogga kulaylka 100+ (1400°C ↔ heerkulka qolka)

• Isbeddel aan kala go 'lahayn oo ku yimaada heerkulka sare ee joogtada ah

Codsiyada Muhiimka ah ee Dib loo Shaaciyay

1. Soo saarista Baytariga Litium-ka

- Isku-hagaajin sax ah oo loogu talagalay sintering-ka walxaha elektiroonigga ah

- Maareynta katoodhada NMC/LFP ee aan wasakhda lahayn

- Hawlgal deggan oo lagu yareynayo jawiga

2. Habaynta Dhoobada Sare

- Taageero aan lahayn wareeg oo loogu talagalay taayirrada qaab-weyn (ilaa 1.5 × 3m)

- Xakameyn xawaare oo joogto ah oo ku saabsan khadadka muraayadaha qalabka nadaafadda

- Dhammaystirka dusha sare ee aan calaamadda lahayn (Ra <0.8μm)

3. Soo saarista Walxaha Birlabta ah

- Wareeg aan gariir lahayn oo loogu talagalay sintering ferrite ah oo ku saleysan

- Dareeraha kiimikada ee deegaannada hodanka ku ah haydarojiin

Faa'iidooyinka Hawlgalka

Awoodda Rarka: Waxay taageertaa miisaan ka weyn 3-5× dhererkiiba marka loo eego duubayaasha birta ah

Iska caabbinta Isbeddelka: Waxay ilaalisaa <0.05mm/m toosan ka dib 10,000 saacadood oo shaqo ah

Waxtarka Tamarta: 18-22% ayaa hoos u dhigtay isticmaalka tamarta foornada iyada oo loo marayo qaybinta kulaylka ee la hagaajiyay

Iswaafajinta Warshadaha Kala Duwan: La qabsan karo foornada baabuurta la shito, foornada duuban ee lakabka badan leh, iyo foornada tunnel-ka isku-dhafan

Joogtaynta Dhaqaalaha

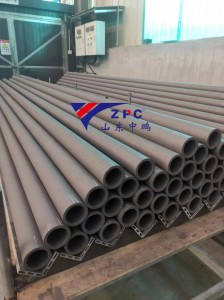

Iyadoo ay u baahan tahay maalgashi bilow ah oo 30-40% ka sarreeya rollers-ka caadiga ah, xalalka R-SiC waxay muujinayaan:

- 70% muddo dheer oo adeeg ah (5-7 sano marka la barbar dhigo 2-3 sano)

- 90% dib-u-warshadayn iyada oo loo marayo hababka dib-u-soo-celinta kulaylka

- 60% kharashka dayactirka oo ka hooseeya meelaha u adkaysta xoqidda

Naqshad Diyaar u ah Mustaqbalka

Roollada casriga ah ee R-SiC hadda waxay ka kooban yihiin:

- Godadka raadraaca ee lagu xardhay laser-ka ee khadadka wax soo saarka ee otomaatiga ah

- Porosity la habeyn karo si loo helo jawi gaar ah oo la isku halleyn karo

- Dareemayaal kuleyl oo isku dhafan oo loogu talagalay hawlgallada foornada casriga ah

Horumarradan tignoolajiyada ah waxay u dhigaan duubayaasha carbide-ka silicon-ka ee falcelinta ku shaqeeya inay yihiin qaybo aan laga maarmi karin nidaamyada kuleylinta warshadaha ee jiilka soo socda, taasoo u oggolaanaysa soosaarayaasha inay gaaraan xakamaynta heerkulka oo adag, joogtaynta badeecada oo sareysa, iyo socodka shaqada wax soo saarka ee waara ee qaybaha badan ee tignoolajiyada sare.

Shirkadda Shandong Zhongpeng Special Ceramics Co., Ltd waa mid ka mid ah xalalka ugu waaweyn ee walxaha cusub ee dhoobada ah ee silicon carbide ee Shiinaha. Dhoobada farsamada ee SiC: Adkaanshaha Moh waa 9 (adkeysiga New Moh waa 13), oo leh iska caabin aad u fiican oo ka dhan ah nabaad-guurka iyo daxalka, xoqid aad u fiican - iska caabin iyo ka-hortagga oksaydhka. Nolosha adeegga ee badeecada SiC waa 4 ilaa 5 jeer ka dheer 92% walxaha alumina. MOR ee RBSiC waa 5 ilaa 7 jeer ka badan SNBSC, waxaa loo isticmaali karaa qaabab badan oo adag. Habka xigashada waa mid degdeg ah, gaarsiintu waa sidii la ballanqaaday tayadana waa mid aan la barbar dhigi karin. Had iyo jeer waxaan ku adkaysannaa inaan ka hortagno yoolalkayaga oo aan qalbiyadeenna dib ugu celinno bulshada.