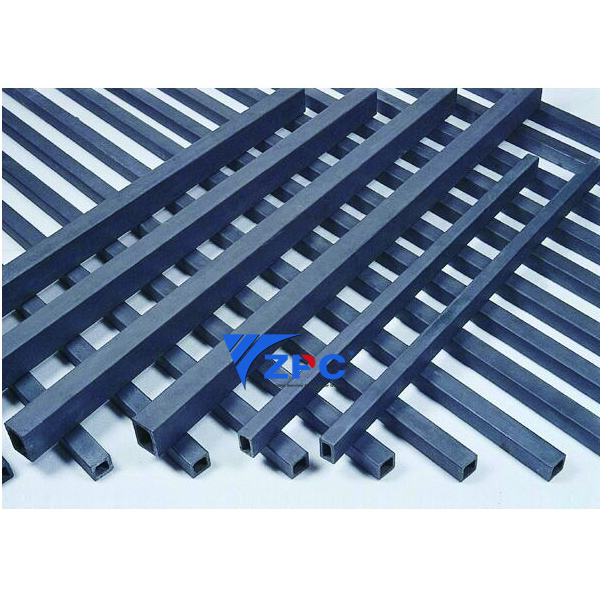

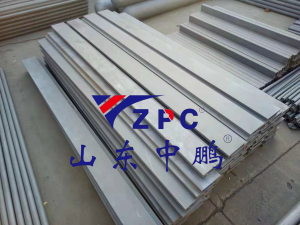

Matanda esilicon carbide

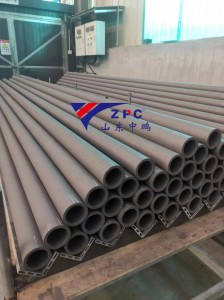

Marori esimbi esilicon carbide (R-SiC) anogadzirwa nesimbiDzakabuda sezvinhu zvakakosha mumazuva ano ekugadzirisa kupisa, kunyanya kugona kugadzira mabhatiri e lithium, kugadzira ceramics yepamusoro, uye kugadzira zvinhu zvine magnetic sintering nemazvo. Aya maroller akasarudzika anotsanangura patsva mwero wekushanda mumaovheni eindasitiri anodziya zvakanyanya nekugadzirisa matambudziko makuru ekugadzikana kwekupisa uye kugara kwenguva refu kwemakanika.

Kushanda Kwekupisa Kusingaenzaniswi

Yakagadzirwa kuti ishande nguva dzose pa1450-1600°C - yakakwirira zvakanyanya kupfuura maroller ekare ealumina - maroller eR-SiC anochengetedza divi rakanyatsojeka kunyangwe kana paine kupisa kwakanyanya. Magadzirirwo awo akasiyana anogonesa:

• Kufanana kwekupisa nekukurumidza (±5°C pakureba kweroller)

• Kutsungirira kutenderera kwekupisa kwe100+ (1400°C ↔ tembiricha yemukamuri)

• Kusachinja-chinja kwesimba remudumbu kana tembiricha yakakwira yaramba iripo

Maitiro Akakosha Akatsanangurwa Patsva

1. Kugadzirwa kweMabhatiri eLithium

- Kurongeka kwakarurama kwekushomeka kwezvinhu zve electrode

- Kubatwa kweNMC/LFP cathodes pasina kusvibiswa

- Kushanda kwakasimba mukuderedza mhepo

2. Kugadziriswa Kwepamusoro kweCeramics

- Rutsigiro rusina warp rwemataira makuru (kusvika 1.5×3m)

- Kudzora kumhanya nguva dzose mumitsetse yegirazi rezvishandiso zvekuchenesa

- Kupera kwekumusoro kusina kunyorwa (Ra <0.8μm)

3. Kugadzira Zvinhu Zvinoshandisa Magneti

- Kutenderera kusina kudedera kwesimbi yeferrite yakatarisana

- Kusashanda kwemakemikari munzvimbo dzine hydrogen yakawanda

Zvakanakira Kushanda

Kugona Kutakura: Inotsigira huremu hwakakura hwe3-5 × pahurefu hweyuniti vs. maroller esimbi alloy

Kuramba Kuchinja: Inochengetedza kutwasuka <0.05mm/m mushure memaawa gumi ekushanda

Kushanda Nesimba: 18-22% kuderedzwa kwesimba rechoto kuburikidza nekugoverwa kwekupisa kwakagadziridzwa

Kuenderana Kwemaindasitiri Akawanda: Kunogona kushandiswa kumakilni ekufambisa, nzvimbo dzemoto dzinotenderedza zvinhu zvakawanda, uye maovheni emugero wehybrid

Kugara Kwehupfumi Hwakasimba

Kunyange zvazvo zvichidikanwa mari yekutanga yepamusoro ne30-40% kupfuura maroller akajairwa, mhinduro dzeR-SiC dzinoratidza:

- 70% nguva dzebasa dzakareba (makore 5-7 vs. makore 2-3)

- 90% inogona kudzokororwazve kuburikidza nemaitiro ekupisa

- 60% mitengo yekuchengetedza yakaderera kubva panzvimbo dzisingakuvadzi

Dhizaini Yakagadzirira Ramangwana

Maroller emazuva ano eR-SiC ikozvino anosanganisira:

- Migero yekutevera yakagadzirwa neLaser yemitsetse yekugadzira otomatiki

- Kugona kugadziriswa kwenzvimbo yemhepo chaiyo

- Ma sensor ekupisa akabatanidzwa ekushanda kwehwhini yakangwara

Kufambira mberi uku kwetekinoroji kunoita kuti ma "reaction-sintered silicon carbide rollers" ashande sezvinhu zvakakosha muzvigadzirwa zveindasitiri zvechizvarwa chinotevera, zvichibvumira vagadziri kuti vagone kudzora tembiricha zvakanyanya, kugara kwenguva refu kwezvigadzirwa, uye kugadzira zvinhu nenzira inochengetedza mafambiro ebasa munzvimbo dzakasiyana-siyana dzetekinoroji yepamusoro.

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yemhando huru dzesilicon carbide ceramic itsva muChina. SiC technical ceramic: Kuomarara kwaMoh kwa9 (Kuomarara kwaNew Moh kwa13), nekusimba kwakanaka pakukukurwa nekuora, kusimba kwakanaka - kusimba uye kudzivirira oxidation. Hupenyu hwebasa rechigadzirwa cheSiC hwakareba ka4 kusvika ka5 kupfuura 92% alumina material. MOR yeRBSiC yakapetwa ka5 kusvika ka7 kupfuura SNBSC, inogona kushandiswa kune mamwe maumbirwo akaomarara. Maitiro ekukosha kwemashoko anokurumidza, kuendesa kwacho kwakaitwa sezvakavimbiswa uye mhando yacho haina kukosha. Tinogara tichiramba tichipikisa zvinangwa zvedu uye tinopa moyo yedu kunharaunda.