Miyala ya silicon carbide

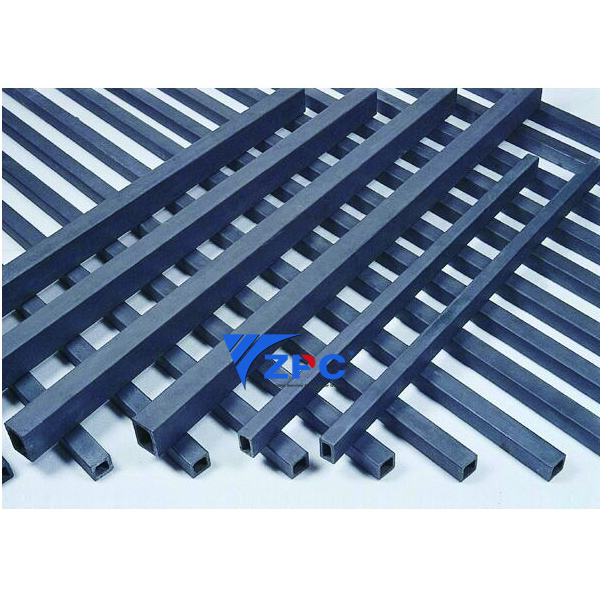

Ma ceramic roller a silicon carbide (R-SiC) opangidwa ndi Reaction-sinteredMa rollers apaderawa akuwonekera ngati zinthu zofunika kwambiri mu makina amakono opangira kutentha, makamaka popanga mabatire a lithiamu, kupanga zinthu zadothi zapamwamba, komanso kuyeretsa zinthu zamaginito molondola. Ma rollers apaderawa amatanthauziranso miyezo yogwirira ntchito m'mafakitale otentha kwambiri pothana ndi mavuto akuluakulu pakukhazikika kwa kutentha komanso kulimba kwa makina.

Magwiridwe Osayerekezeka a Kutentha

Ma rollers a R-SiC omwe adapangidwa kuti azigwira ntchito mosalekeza pa 1450-1600°C - okwera kwambiri kuposa ma rollers a alumina achikhalidwe - amasunga kulondola kwa mawonekedwe ngakhale kutentha kwambiri. Kapangidwe kawo kapadera kamalola:

• Kusamutsa kutentha mwachangu mofanana (±5°C kutalika kwa roller)

• Kupirira kutentha kwa 100+ (1400°C ↔ kutentha kwa chipinda)

• Kusasinthika konse kwa mafunde pa kutentha kwakukulu komwe kumapitirirabe

Mapulogalamu Ofunika Asinthidwanso

1. Kupanga Mabatire a Lithium

- Kulinganiza bwino zinthu za elekitirodi

- Kugwiritsa ntchito ma cathode a NMC/LFP popanda kuipitsidwa

- Kugwira ntchito kokhazikika pochepetsa mpweya

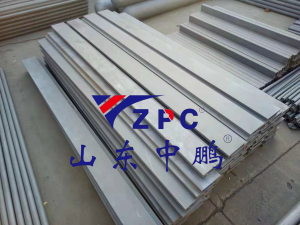

2. Kukonza Zinthu Zapamwamba Zopangira Zadothi

- Thandizo lopanda kupotoka la matailosi akuluakulu (mpaka 1.5×3m)

- Kuwongolera liwiro nthawi zonse m'mizere yowunikira ziwiya zaukhondo

- Kumaliza kwa pamwamba kosalemba (Ra <0.8μm)

3. Kupanga Zinthu Zogwiritsa Ntchito Maginito

- Kuzungulira kopanda kugwedezeka kwa ferrite sintering yolunjika

- Kusagwira ntchito kwa mankhwala m'malo okhala ndi haidrojeni wambiri

Ubwino Wogwirira Ntchito

Kutha Kunyamula: Kumathandizira kulemera kwakukulu kwa 3-5 × pa unit kutalika poyerekeza ndi ma rollers a alloy achitsulo

Kukana Kusintha: Kusunga kulunjika kwa <0.05mm/m patatha maola 10,000 ogwira ntchito

Kugwiritsa Ntchito Mphamvu Mwachangu: 18-22% kuchepetsa kugwiritsa ntchito mphamvu mu uvuni kudzera mu kugawa kutentha koyenera

Kugwirizana kwa Makampani Osiyanasiyana: Kutha kusinthidwa ndi ma shuttle kilns, ma multi-layer roller hearths, ndi ma hybrid tunnel furnaces

Kukhazikika kwa Zachuma

Ngakhale kuti ndalama zoyambira zimafunika ndalama zokwana 30-40% kuposa ma rollers achikhalidwe, mayankho a R-SiC akuwonetsa izi:

- 70% nthawi yayitali yogwirira ntchito (zaka 5-7 poyerekeza ndi zaka 2-3)

- 90% yobwezeretsanso pogwiritsa ntchito njira zotenthetsera

- 60% yotsika mtengo yokonza zinthu kuchokera pamalo osapsa

Kapangidwe Kokonzeka M'tsogolo

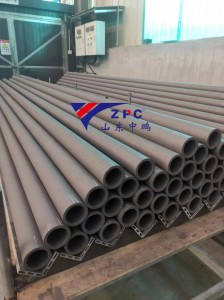

Ma rollers amakono a R-SiC tsopano akuphatikizapo:

- Mizere yotsatirira yojambulidwa ndi laser ya mizere yopangira yokha

- Ma porosity osinthika kuti mpweya ulowerere bwino

- Zosewerera kutentha zophatikizidwa kuti zigwire ntchito mu uvuni wanzeru

Kupita patsogolo kwa ukadaulo kumeneku kumaika ma rollers a silicon carbide opangidwa ndi reaction-sintered ngati zinthu zofunika kwambiri mu makina otenthetsera mafakitale a m'badwo wotsatira, zomwe zimathandiza opanga kuti azitha kuwongolera kutentha kwambiri, kusinthasintha kwa zinthu, komanso kupanga zinthu mokhazikika m'magawo ambiri apamwamba.

Shandong Zhongpeng Special Ceramics Co., Ltd ndi imodzi mwa njira zazikulu kwambiri zothetsera zinthu zatsopano za silicon carbide ceramic ku China. SiC technical ceramic: Kuuma kwa Moh ndi 9 (Kuuma kwa New Moh ndi 13), komwe kumalimbana bwino ndi kukokoloka ndi dzimbiri, kukana bwino kwambiri - kukana komanso kukana okosijeni. Moyo wa ntchito wa SiC ndi wautali nthawi 4 mpaka 5 kuposa 92% alumina. MOR ya RBSiC ndi nthawi 5 mpaka 7 kuposa ya SNBSC, ingagwiritsidwe ntchito pazinthu zovuta kwambiri. Njira yowerengera mawu ndi yachangu, kutumiza kumakhala monga momwe kunalonjezera ndipo khalidwe lake ndi lapamwamba kwambiri. Nthawi zonse timapitilizabe kutsutsa zolinga zathu ndikubwezera mitima yathu kwa anthu.