Gilashin silicon carbide

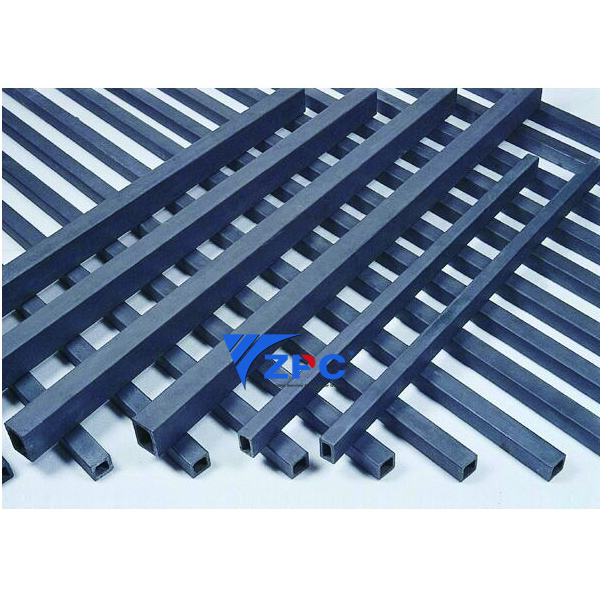

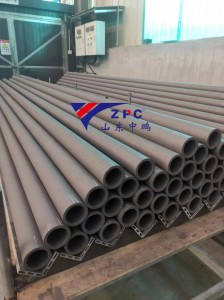

Na'urorin jujjuyawar yumbu na silicon carbide (R-SiC) masu haɗakar amsawasun fito a matsayin muhimman abubuwa a tsarin sarrafa zafi na zamani, musamman a fannin kera batirin lithium, samar da yumbu mai inganci, da kuma daidaita simintin ƙarfe mai maganadisu. Waɗannan na'urori na musamman suna sake fasalta ƙa'idodin aiki a cikin tanderun masana'antu masu zafi sosai ta hanyar magance manyan ƙalubalen daidaiton zafi da dorewar injina.

Aikin Zafin da Ba a Daidaita ba

An ƙera shi don ya ci gaba da aiki a zafin 1450-1600°C - ya fi na'urorin jujjuyawar alumina na gargajiya girma - na'urorin jujjuyawar R-SiC suna kiyaye daidaiton girma koda a lokacin zagayowar zafi mai tsanani. Tsarin su na musamman yana ba da damar:

• Daidaito tsakanin canja wurin zafi da sauri (±5°C a tsawon abin naɗawa)

• Jure wa zagayowar girgizar zafi sama da 100 (1400°C ↔ zafin ɗaki)

• Sifili nakasa a yanayin zafi mai tsanani mai dorewa

An Sake Fasalta Manhajoji Masu Muhimmanci

1. Samar da Batirin Lithium

- Daidaito mai kyau don haɗa kayan lantarki

- Gudanar da cathodes na NMC/LFP ba tare da gurɓatawa ba

- Aiki mai dorewa wajen rage yanayi

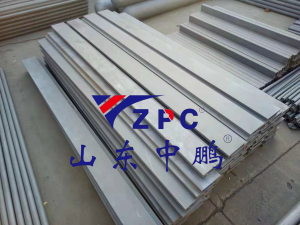

2. Sarrafa Cikakkun Kayan Karafa

- Tallafin da ba ya buƙatar warp don manyan tayal (har zuwa 1.5 × 3m)

- Daidaita saurin gudu a cikin layukan gilashin kayan tsafta

- Kammalawar saman da ba ta da alama (Ra <0.8μm)

3. Kera Kayan Magnetic

- Juyawa mara girgiza don daidaita sintering na ferrite

- Rashin daidaiton sinadarai a cikin muhalli mai wadataccen hydrogen

Fa'idodin Aiki

Ƙarfin Lodi: Yana goyon bayan nauyi mafi girma na 3-5× a kowane tsawon raka'a idan aka kwatanta da na'urorin ƙarfe masu juyawa

Juriyar Canzawa: Yana riƙe da <0.05mm/m madaidaiciya bayan sa'o'i 10,000 na aiki

Ingancin Makamashi: An rage amfani da makamashin tanderu kashi 18-22% ta hanyar ingantaccen rarraba zafi

Yarjejeniyar Masana'antu: Mai dacewa da murhun motoci, murhun birgima mai layuka da yawa, da kuma tanderun rami masu haɗaka

Dorewa a Tattalin Arziki

Duk da cewa ana buƙatar saka hannun jari na farko da kashi 30-40% fiye da na'urorin rollers na gargajiya, hanyoyin R-SiC sun nuna:

- Tsawon lokacin sabis na 70% (shekaru 5-7 idan aka kwatanta da shekaru 2-3)

- Kashi 90% na sake amfani da shi ta hanyar hanyoyin sake amfani da zafi

- Rage farashin gyara kashi 60% daga saman da ke jure wa gogewa

Tsarin Shirye-shirye na Nan gaba

Na'urorin R-SiC na zamani yanzu sun haɗa da:

- Ramin bin diddigin da aka sassaka da Laser don layukan samarwa ta atomatik

- Porosity na musamman don takamaiman yanayin iska

- Na'urori masu auna zafi da aka haɗa don ayyukan kiln mai wayo

Waɗannan ci gaban fasaha suna sanya rollers na silicon carbide masu haɗakar amsawa a matsayin abubuwan da ba makawa a cikin tsarin dumama masana'antu na gaba, wanda ke ba masana'antun damar cimma ingantaccen sarrafa zafin jiki, daidaiton samfura mafi girma, da kuma ayyukan samar da kayayyaki masu ɗorewa a fannoni daban-daban na fasaha.

Kamfanin Shandong Zhongpeng Special Ceramics Co., Ltd yana ɗaya daga cikin manyan hanyoyin samar da sabbin kayan yumbu na silicon carbide a China. SiC technical yumbu: Taurin Moh shine 9 (taurin New Moh shine 13), tare da kyakkyawan juriya ga zaizayar ƙasa da tsatsa, kyakkyawan juriya - juriya da hana iskar shaka. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da kayan alumina 92%. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani da shi don siffofi masu rikitarwa. Tsarin ƙididdigewa yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da nasaba da komai. Kullum muna ci gaba da ƙalubalantar manufofinmu kuma muna mayar da zukatanmu ga al'umma.