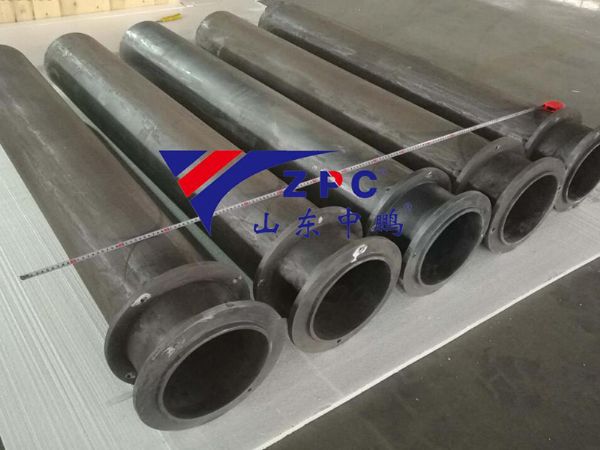

Iityhubhu ze-silicon carbide ezikhazimlayo

Iityhubhu ze-silicon carbide ezikhazimlayoZizinto zeseramikhi eziphambili ezaziwa kakhulu ngokusebenza kwazo ngendlela egqwesileyo kwizicelo zoshishino ezishushu kakhulu nezirhabaxa. Iimpawu zazo zezinto ezisetyenzisiweyo kunye nokuguquguquka kwesakhiwo kuzenza zibe yimfuneko kwiimeko zokusebenza ezinzima. Apha ngezantsi kukho isishwankathelo seenzuzo kunye nokusetyenziswa kwazo.

1. Iipropati zezinto eziBalaseleyo

I-SiC yinto yeseramikhi esebenza kakuhle eneempawu ezibalaseleyo:

(1)Ukumelana nobushushu obugqithisileyo: Iyakwazi ukusebenza ngokuqhubekayo kumaqondo obushushu afikelela kwi-1600°C kunye nokuvezwa kwexesha elifutshane okugqitha i-1800°C, idlula kakhulu izisombululo zemveli ezisekwe kwisinyithi.

(2)Ukuqhuba Okuphezulu Kobushushu: Ngokuqhuba okungaphezulu ngokuphindwe kabini ukuya kathathu kuneentsimbi, iityhubhu ze-silicon carbide ezikhazimlayo zivumela ukufudumeza okukhawulezayo kunye nokusasazwa kobushushu obufanayo.

(3)Ukwanda kobushushu obuphantsi: Ukwanda kobushushu obuncinci kunciphisa uxinzelelo ngexesha lokutshintsha kobushushu, okuqinisekisa uzinzo lwesakhiwo.

(4)Ukuxhathisa ukubola kunye nokubola: Ayimelani nee-asidi, ii-alkali, iintsimbi ezinyibilikisiweyo, kunye neegesi ezirhabaxa, nokuba kuphantsi kweemeko zobushushu obuphezulu ezihlala ixesha elide.

2. Ukuguquguquka kwesakhiwo

Iityhubhu ze-silicon carbide radiant zinokulungiswa ngokweemfuno ezahlukeneyo zoshishino:

(1)Iiyilo ezinokwenziwa ngokwezifiso: Zifumaneka zilungelelaniswe ngokuthe ngqo, zimile okwe-U, okanye zimile okwe-W ukuze kuphuculwe ukusasazwa kobushushu kunye nokusetyenziswa kwendawo.

(2)Ukuhlanganiswa Okuqinileyo: Iyahambelana nee-flange zesinyithi okanye iinkqubo zokutywina ze-ceramic ukuze kuqhagamshelwe unxibelelwano olungenako ukuvuza kwiisetingi ezintsonkothileyo.

- Iingenelo zokusebenza

(1)Ukusebenza kakuhle kwamandla: Ubushushu obuphezulu bunciphisa ukusetyenziswa kwamandla ngokuvumela ukudluliselwa kobushushu ngokukhawuleza.

(2)Ubomi obude benkonzo: Iityhubhu ze-silicon carbide ezikhazimlayo zihlala ixesha elide ngokuphindwe kathathu ukuya kahlanu kunezinye iindlela zesinyithi kwiindawo ezinzima, nto leyo enciphisa ixesha lokungasebenzi kunye neendleko zokutshintsha.

(3)Ukumelana Nokutshatyalazwa Kobushushu: Imelana nemijikelo yokufudumeza nokupholisa ngokukhawuleza ngaphandle kokuqhekeka, ifanelekile kwiinkqubo ezifuna utshintsho lobushushu rhoqo.

4. Izicelo eziphambili zemizi-mveliso

Iityhubhu ze-silicon carbide radiant zigqwesile kumacandelo abalulekileyo:

(1)I-Metallurgy: Isetyenziswa kwii-annealing oven, kwii-carburizing oven, nakwiinkqubo ze-brazing ukuze kunyangwe ubushushu obufanayo.

(2)Ukucubungula ngeekhemikhali: Kusebenza njengeetyhubhu zokusabela okanye izixhasi ze-catalyst kwii-reactors ezishushu kakhulu kunye nee-pyrolysis furnaces.

(3)Ukwenziwa kweeCeramics/Glass: Qinisekisa ulawulo oluchanekileyo lobushushu kwii-ovens ezitshisayo kunye nee-ovens ezinyibilikisa iglasi.

(4)Iinkqubo zeNdalo: Zifakwa kwiindawo zokutshisa inkunkuma nakwiiyunithi zonyango lokukhupha umsi ukuze kulawulwe iigesi ezirhabaxa kumaqondo obushushu aphezulu.

5. Iingenelo zokuthelekisa ngaphezu kwezinye iindlela:

| Ipropathi | Iityhubhu ze-silicon carbide ezikhazimlayo | Iityhubhu zesinyithi | Iityhubhu zeQuartz |

| Ubushushu Obuphezulu | 1600℃ | <1200℃ | <1200 ℃ (ixesha elifutshane) |

| Ukumelana nokugqwala | Igqwesile | Iphakathi | Ayilunganga kwiindawo ezine-alkaline |

| Ukumelana noTshabalalo oluTshisayo | Phezulu | Iphantsi | Iphakathi |

6. Kutheni Ukhetha iityhubhu ze-silicon carbide ezikhazimlayo?

Iityhubhu ze-silicon carbide radiant zezona zikhetho zifanelekileyo kumashishini abeka phambili:

(1) Uzinzo lobushushu obugqithisileyo ngaphandle kokuwohloka kokusebenza.

(2)Ukuthembeka kwexesha elide kwiindawo ezirhabaxa okanye ezikhupha ioksijini.

(3)Ukufudumala okusebenzisa amandla kakuhle nangokulinganayo kwiinkqubo eziqhutywa ngokuchanekileyo.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zinkulu zezinto ezintsha ze-silicon carbide ceramic eTshayina. I-SiC technical ceramic: Ubunzima bukaMoh buyi-9 (Ubunzima bukaMoh obuyi-13), bunokumelana okuhle nokukhukuliseka kunye nokugqwala, ukukrala okugqwesileyo - ukumelana nokubola kunye nokuchasana ne-oxidation. Ubomi benkonzo yemveliso yeSiC bubude obuphindwe ka-4 ukuya ku-5 kune-92% ye-alumina material. I-MOR ye-RBSiC iphindwe ka-5 ukuya ku-7 kune-SNBSC, ingasetyenziselwa iimilo ezinzima ngakumbi. Inkqubo yokucaphula iyakhawuleza, ukuhanjiswa kunjengoko kuthembisiwe kwaye umgangatho awulingani. Sihlala siqhubeka nokuchasa iinjongo zethu kwaye sibuyisela iintliziyo zethu kuluntu.